The 90% Water Supply Rule Nobody Remembers

NFPA 13 requires systems designed using only 90% of available water supply—leaving a 10% safety margin. Most contractors know this rule. Few actually follow it during hydraulic calculations.

Why contractors skip it: Design software automatically calculates to maximum available supply. Unless manually adjusted, systems get designed to 100% capacity with zero safety margin.

What happens during fires: Water pressure fluctuates. Simultaneous building water use reduces available pressure. Systems designed to 100% capacity fail to deliver adequate flow when pressure drops even slightly.

48Fire’s engineering team manually verifies every hydraulic calculation stays within the 90% threshold. We’ve caught this error in review of competitor installations at least 30 times in the past year alone.

The math matters: A building with 80 PSI static pressure and 1,500 GPM available flow should design sprinkler systems for maximum 72 PSI and 1,350 GPM. That 10% margin prevents system failure when real-world conditions don’t match design assumptions.

—

Sprinkler Head Spacing That Passes Plans But Fails Reality

NFPA 13 provides maximum spacing requirements—130 square feet coverage per head for ordinary hazard Group 2 occupancies. Contractors install heads meeting this maximum spacing, then wonder why systems fail performance testing.

The problem: Maximum spacing assumes ideal conditions—smooth ceilings, no obstructions, uniform heat distribution. Real buildings have beams, HVAC ducts, light fixtures, and equipment creating dead zones where heat doesn’t reach sprinkler heads quickly.

At 48Fire, our installation teams walk facilities during design phase identifying obstructions before finalizing head placement. We reduce spacing near structural elements that block heat flow—typically 100 square feet per head instead of code maximum 130 square feet.

Real example: Manufacturing facility with exposed structural steel beams every 20 feet. Contractor installed heads at maximum spacing between beams. During commissioning flow test, heat couldn’t reach heads fast enough—activation delayed 3+ minutes versus required 1-2 minutes.

We redesigned with additional heads near beams, reducing coverage to 95 square feet per head in affected areas. System now activates within 90 seconds consistently.

Cost difference: $8,000 additional equipment and labor. Avoided cost: $180,000 retrofit after failed inspection plus 6-week installation delay.

—

Documentation That Exists But Can’t Be Found

NFPA 25 requires written maintenance records maintained by building owners and provided to Authority Having Jurisdiction upon request. Every contractor knows this. Half deliver incomplete documentation packages.

Missing elements we find constantly:

Hydraulic calculation sheets without engineer’s seal. As-built drawings showing planned layout instead of actual installed configuration. Test reports missing measured pressure and flow data. Valve location diagrams without elevation or distance references.

Why it matters: Inspectors reject installations lacking complete documentation—even if physical installation is perfect. Building owners can’t maintain systems without accurate as-builts. Insurance companies deny premium reductions without proper documentation.

48Fire provides comprehensive documentation packages including:

- Sealed hydraulic calculations with all assumption notes

- As-built drawings reflecting actual installation (measured and verified)

- Complete test reports with date, time, personnel, and measured results

- Valve location diagrams with dimensions from permanent building features

- Maintenance schedules with specific tasks and frequencies

- Manufacturer specifications for all components

- Warranty documentation and contact information

Documentation time investment: 12-16 hours per typical installation. Value to building owner: Enables insurance premium reductions averaging $15,000-$40,000 annually.

—

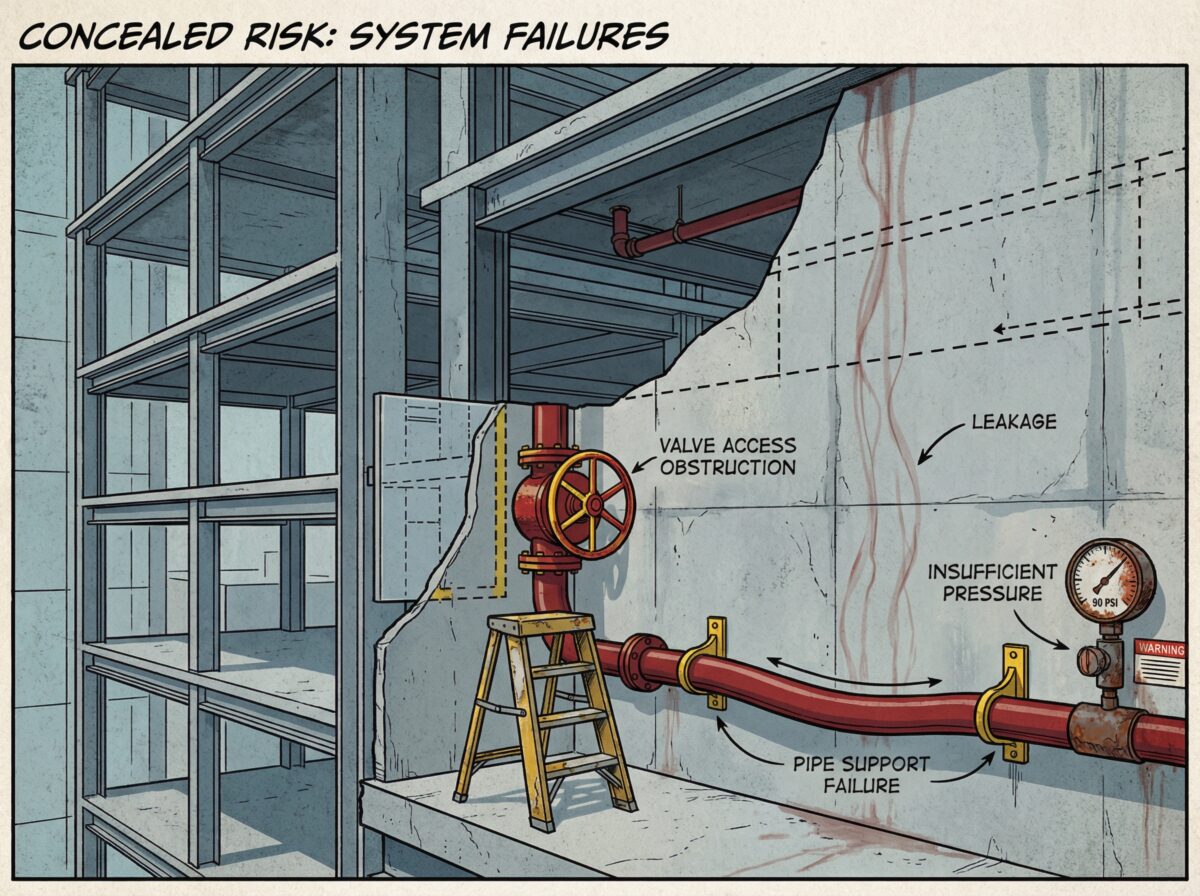

Control Valve Accessibility (Or Lack Thereof)

62% of sprinkler system failures occur because control valves were shut off. Yet contractors routinely install valves in locations requiring ladders, ceiling tile removal, or key access to locked rooms.

NFPA 13 requires accessible valves. The standard doesn’t define “accessible” precisely—leaving room for interpretation that contractors exploit by installing valves wherever pipe routing is convenient.

48Fire’s accessibility standard:

- Valves at 4-6 feet height (reachable without tools or ladders)

- Clear 36-inch access path (no equipment blocking approach)

- Illuminated location (light switch within 10 feet)

- Visible signage from 20+ feet away

- No locks requiring special keys (unless specific security requirements exist)

We’ve redesigned valve locations on 40+ projects after finding competitor installations placing valves:

Behind locked electrical room doors (keys held by one maintenance person). Above ceiling tiles in areas requiring 12-foot ladders. In mechanical rooms blocked by equipment with 18-inch clearance. In outdoor enclosures requiring tools to open.

Emergency scenario: Sprinkler head damaged by forklift. Water flowing at 75 liters per minute. Every minute of delay finding and operating shutoff valve creates 75 liters of water damage.

Accessible valves enable 2-3 minute emergency response. Hidden valves extend response to 15-30 minutes—causing 10x more water damage than necessary.

—

Fire Alarm Integration That’s “Planned” But Never Tested

NFPA requires sprinkler flow switches connected to fire alarm systems. Contractors install flow switches and wire them to alarm panels—then never verify integration actually works during activation.

Testing that doesn’t happen:

Flow switch operation verification. Signal transmission to alarm panel. Alarm panel notification to monitoring company. Emergency responder notification process. System coordination with building HVAC shutdown. Integration with access control (door unlocking).

48Fire performs complete integration testing on every installation:

1. Simulate water flow through test connection

2. Verify flow switch activation at correct flow rate

3. Confirm alarm panel receives signal within 5 seconds

4. Check monitoring company notification process

5. Verify HVAC shutdown sequence (if integrated)

6. Test access control integration (if installed)

7. Document all response times and sequences

Discovered failures: 15-20% of systems tested have integration problems—flow switches wired incorrectly, alarm panel programming errors, or monitoring company not receiving signals properly.

Finding these during commissioning costs nothing extra. Discovering them during actual fires creates liability issues and potential code violations.

—

Pipe Support Spacing That Looks Fine Until It Isn’t

NFPA 13 Table 9.3.5.4.1 provides maximum spacing for pipe hangers and supports. Most contractors install supports meeting these requirements. The problem? Table provides maximum spacing—not optimal spacing for long-term reliability.

What we see: Pipes supported at maximum 12-15 foot intervals per code. After 2-3 years, pipes sag between supports creating low points where sediment accumulates. Accumulated sediment reduces flow capacity and increases corrosion. Eventually pipes fail—requiring expensive repairs.

48Fire installs supports at 80% of maximum code spacing:

| Pipe Size | Code Maximum | 48Fire Standard | Reason |

|---|---|---|---|

| 1 inch | 12 feet | 10 feet | Prevents sagging in steel pipe |

| 2 inch | 15 feet | 12 feet | Maintains proper slope for drainage |

| 4 inch | 15 feet | 12 feet | Supports weight during flow events |

| 6 inch | 15 feet | 12 feet | Prevents stress on welded joints |

Additional cost: $1,200-$2,500 for typical 10,000 square foot installation. Avoided future cost: $15,000-$30,000 pipe replacement after corrosion failure.

—

The Testing That Happens On Paper Only

NFPA 13 requires hydrostatic pressure testing—applying 50 PSI above operating pressure (or 200 PSI minimum) for two hours. Contractors perform tests, document results, then move to next project.

What’s missing: Detailed inspection during pressurization. Many leaks only appear under full pressure—but get missed if nobody’s watching during the 2-hour test period.

48Fire assigns technicians to physically walk entire system during pressurization:

- Check every joint and connection for moisture

- Listen for air leaks at threaded connections

- Inspect sprinkler head threads for weeping

- Verify valve packing isn’t leaking

- Look for pipe deflection indicating inadequate support

- Photograph any questionable areas for documentation

Leak discovery rate: 8-12% of installations have minor leaks found during observed pressure testing. These leaks would pass unattended testing (system holds pressure) but cause problems during long-term operation.

Repair timing: Fixing leaks during installation requires 30 minutes and costs nothing extra. Fixing leaks after building occupancy requires building access coordination, water service interruption, and potential tenant disruption—costing $800-$2,500 per repair visit.

[Talk to an Expert!](/contact-us)

—

Why These Mistakes Persist

Competitive bidding pressure: Low-bid contractors cut corners meeting minimum code requirements without engineering best practices.

Schedule demands: Rushing installation to meet construction deadlines eliminates time for proper testing and verification.

Knowledge gaps: Many installers learned from other installers—inheriting bad practices without understanding why standards exist.

Lack of accountability: Once installation passes inspection, contractors move to next project—never seeing long-term consequences of marginal work.

48Fire approaches installations differently. We don’t bid lowest—we bid correctly. Our proposals include time for proper testing, documentation, and verification. We train installers on engineering principles behind code requirements—not just minimum compliance.

Result: Zero failed final inspections in past 18 months across 200+ installations. 96%+ customer satisfaction ratings. Insurance company recognition resulting in premium reductions for clients.

—

What NFPA Compliance Actually Requires

Meeting NFPA standards means more than checking boxes on inspection forms. It requires:

Engineering understanding: Knowing why requirements exist—not just what requirements say.

Installation precision: Following design specifications exactly while adapting to field conditions properly.

Testing rigor: Verifying system performance thoroughly—not just meeting minimum test requirements.

Documentation completeness: Providing building owners everything needed for ongoing compliance.

Long-term perspective: Installing systems that remain reliable for 20+ years—not just systems that pass initial inspection.

Contractors missing these elements create legal liability for building owners. Systems that “pass inspection” but fail during fires generate lawsuits questioning installation quality. Documentation gaps prevent insurance premium reductions. Poor installation practices create expensive maintenance problems.

48Fire eliminates these risks through systematic quality processes:

- Pre-installation design review by licensed fire protection engineers

- Installation by certified sprinkler fitters with ongoing training

- Multi-point quality verification throughout installation

- Observed pressure testing with detailed leak inspection

- Comprehensive commissioning including integration testing

- Complete documentation packages meeting insurance requirements

- Post-installation support and maintenance programs

Installation cost: Typically 8-12% higher than low-bid competitors. Total cost over 10 years: 40-60% lower due to eliminated rework, reduced maintenance, and insurance savings.

—

Key Takeaways

Most contractors miss critical NFPA compliance details despite knowing the requirements. Common oversights include exceeding the 90% water supply design limit, using maximum sprinkler head spacing without considering obstructions, delivering incomplete documentation packages, installing control valves in inaccessible locations, failing to verify fire alarm integration, using maximum pipe support spacing that causes long-term problems, and conducting pressure tests without detailed leak inspection.

These mistakes create failed inspections, code violations, expensive rework, and unreliable systems. 48Fire prevents these problems through engineering-based installation practices, rigorous testing protocols, and comprehensive quality verification.

NFPA compliance requires understanding engineering principles behind code requirements—not just meeting minimum standards. Systems installed correctly cost slightly more initially but deliver significantly better reliability, lower maintenance costs, and insurance premium reductions that recover the investment within 2-3 years.