200 projects. 200 on-time completions. Zero schedule delays.

Timeline reliability isn’t about working faster—it’s about eliminating the unexpected through systematic planning.

The average commercial fire sprinkler installation faces 2-3 delays adding 1-4 weeks to schedules. Common causes: material delivery issues, coordination conflicts with other trades, unforeseen site conditions, inspection delays, design modifications.

48Fire’s approach eliminates these through front-loaded planning, materials management, trade coordination protocols, and design verification before installation begins.

—

Pre-Construction Planning (The 6-Week Head Start)

Most contractors begin planning when they win contracts. 48Fire begins planning during bidding—building project timelines assuming we’ll win before contracts are signed.

Week 1-2: Design Verification

Licensed fire protection engineer reviews construction documents identifying potential issues:

Conflicts with structural elements (beams blocking sprinkler coverage). Coordination requirements with MEP trades (HVAC, electrical, plumbing). Adequate space for pipe routing in congested areas. Access requirements for installation and future maintenance. Code compliance verification against current NFPA standards.

Identified issues go into bid qualifications—not discovery during installation.

Example: Design shows sprinkler main routed through area where HVAC plans show air handler installation. Engineer identifies conflict during review. Bid includes alternate routing with cost impact. General contractor coordinates resolution before construction starts—not after sprinkler contractor mobilizes.

Result: Zero “unforeseen conditions” causing delays during installation. All conditions known and addressed before work begins.

Week 3-4: Materials Procurement

Long-lead items ordered immediately upon contract award:

Fire pumps (12-16 week lead times). Backflow preventers (8-10 weeks). Clean agent suppression equipment (6-8 weeks). Specialized sprinkler heads (4-6 weeks). Fire alarm panels (6-8 weeks).

Standard items pre-staged at 48Fire warehouses:

Pipe and fittings (all common sizes). Standard sprinkler heads (all types used in portfolio). Common fire alarm devices. Valves and trim packages. Hangers and supports.

Material strategy: Order long-lead items immediately, draw standard items from inventory. By installation start, all materials are on-site or confirmed in-transit with tracking numbers.

Competitor approach: Order materials after mobilization. Wait 4-8 weeks for delivery. Installation schedule slips during wait.

Week 5-6: Installation Planning

Project manager develops detailed installation sequence:

Coordination schedule with other trades (when ceiling clear for pipe installation). Crew allocation and skill matching (complex areas get experienced fitters). Equipment needs (lifts, scaffolding, welding machines). Inspection milestones (rough-in, pressure test, final). Testing requirements and coordination. Quality verification checkpoints.

Installation sequence example for 50,000 SF office building:

Day 1-3: Main riser and supply piping (requires building water service coordination)

Day 4-8: Branch line installation on floors 4-6 (working from top down)

Day 9-13: Branch line installation on floors 1-3

Day 14-15: Sprinkler head installation (after ceiling work by others)

Day 16: Pressure testing (witnessed by general contractor inspector)

Day 17-18: Fire alarm wiring and device installation

Day 19: Integration testing and commissioning

Day 20: Final inspection coordination

Daily schedule shared with general contractor 2 weeks before mobilization. Other trades coordinate around this schedule—not reactive coordination during installation.

—

Trade Coordination Protocol

Fire sprinkler installation requires ceiling space shared with electrical, HVAC, plumbing, and communications trades. Schedule delays happen when trades compete for same space simultaneously.

48Fire’s coordination framework:

Coordination Meeting (2 Weeks Before Start)

All ceiling trades attend: sprinkler contractor, HVAC contractor, electrical contractor, plumbing contractor, communications/data contractor.

Meeting agenda:

Review ceiling space constraints. Establish work sequence priority. Identify conflict areas requiring coordination. Agree on coordination drawings (combined MEP layout). Establish daily communication protocol. Set coordination checkpoints.

Outcome: Written coordination plan signed by all trades. Plan identifies who works where and when. Conflicts identified and resolved before anyone mobilizes.

Example coordination agreement:

“HVAC contractor installs main ducts week 1-2. Sprinkler contractor installs mains week 2-3 (coordinating with HVAC). Electrical contractor installs cable tray week 3-4. Sprinkler contractor installs branch lines week 4-5. All trades coordinate final connections week 6.”

Daily Coordination Huddle

15-minute morning meeting with all active ceiling trades:

Today’s work areas for each trade. Potential conflicts needing resolution. Equipment sharing (lifts, scaffolding). Schedule adjustments if weather or other factors affect work.

48Fire participation: Foreman attends daily, communicates plan to crew, escalates conflicts to project manager if field resolution fails.

Result: Problems solved in 15 minutes rather than discovered after trades block each other causing hour or day delays.

Shared Coordination Model

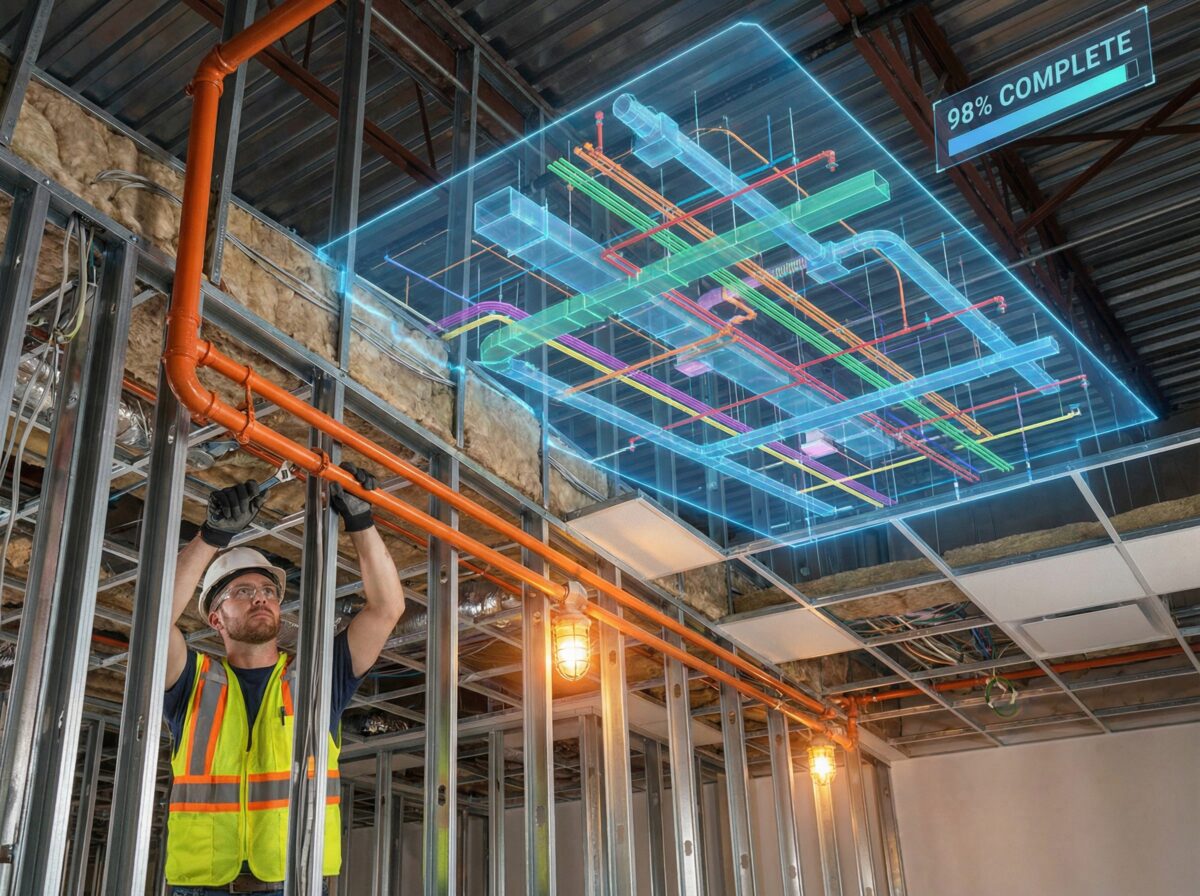

48Fire creates 3D coordination model (BIM – Building Information Modeling) showing sprinkler routing alongside other trades:

Model identifies physical conflicts before installation. All trades review and approve routing. Model used for fabrication (pipe cut to exact lengths). Changes tracked and coordinated through model updates.

Technology investment: $8,000-$12,000 per project for modeling. Saved time: 1-2 weeks eliminating field rework from conflicts. Additional benefit: As-built documentation generated automatically from model.

—

Materials Management System

Material delays kill schedules. Wrong materials delivered, damaged materials discovered during installation, quantity miscalculations requiring additional orders—all cause delays.

48Fire’s materials protocol:

Pre-Installation Verification

One week before installation start:

Verify all materials staged at warehouse or confirmed in transit. Physical count of inventory items. Inspection for shipping damage. Comparison against approved submittal documents. Confirmation quantities match installation requirements.

Quality checkpoint: Materials supervisor (not project manager) conducts verification. Independent check catches quantity errors or damaged items before delivery to jobsite.

Discovery frequency: 3-5% of projects have material issues identified during pre-installation verification—wrong head types ordered, damaged pipe in shipment, insufficient quantities calculated. Caught during verification, these correct without schedule impact. Discovered on jobsite during installation, these cause 3-7 day delays.

Just-In-Time Delivery

Materials delivered to jobsite 2-3 days before needed:

Prevents theft or damage from extended storage. Reduces jobsite congestion. Ensures materials available when needed without excessive inventory.

Delivery sequence example:

Day -2: Main riser materials (large pipe, valves, backflow preventer)

Day 3: Floor 4-6 branch line materials

Day 8: Floor 1-3 branch line materials

Day 13: Sprinkler heads and trim materials

Day 17: Fire alarm devices and wiring

Each delivery timed to crew progression through building.

Inventory Tracking System

Digital system tracks materials from order through installation:

Purchase order creation and vendor confirmation. Shipment tracking (GPS on delivery trucks). Warehouse receipt verification. Jobsite delivery confirmation. Installation consumption logging. Waste/remaining material tracking.

Benefit: Real-time visibility into material status. Project manager knows exact inventory without physical counts. Automatic reorder alerts prevent running out.

System integration: Connected to project schedule. System alerts when materials needed for upcoming tasks aren’t confirmed available.

[Talk to an Expert!](/contact-us)

—

Quality Verification Preventing Rework

Rework creates schedule delays—work done incorrectly requires removal and reinstallation consuming double time.

48Fire’s quality framework:

Daily Quality Inspections

Foreman inspects previous day’s work each morning:

Sprinkler head spacing verification. Pipe support spacing and type. Proper hanger installation. Valve accessibility. Clearance requirements met. Workmanship quality.

Problems identified early: Correction takes minutes. Problems discovered during final inspection take days (removing finished ceiling, accessing pipe, correcting, replacing ceiling).

Inspection documentation: Foreman photographs daily work with timestamp. Creates visual record showing progression and quality. Photos useful resolving disputes or questions during final inspection.

Weekly Engineer Review

48Fire engineer visits jobsite weekly during installation:

Verifies installation matches design intent. Checks complex areas requiring engineering judgment. Reviews any field modifications for hydraulic impact. Coordinates resolution of unforeseen conditions.

Engineer authority: Can stop work if installation deviates from approved design. Prevents installing substantial work incorrectly requiring demolition and reinstallation.

Frequency of stops: 2-3% of projects have engineer-initiated work stops—typically catching errors affecting few devices rather than entire systems. Minor delays (hours to day) preventing major delays (weeks for rework).

Pre-Inspection Quality Audit

Senior 48Fire inspector (not project team) audits installation before final inspection:

Comprehensive checklist covering all inspection points. Deficiency list with photos and locations. Correction timeframe assessment. Re-inspection after corrections.

Internal audit timing: Conducted 3-5 days before scheduled final inspection. Deficiencies corrected before inspector arrives.

Result: Zero failed final inspections requiring reinspection scheduling (2-4 week delays). Inspector verifies rather than discovers.

—

Permitting and Inspection Coordination

Inspection delays occur when inspectors unavailable, paperwork incomplete, or prerequisites not met.

48Fire’s inspection protocol:

Early Permit Application

Permits applied for 6-8 weeks before installation start:

Complete submittal packages (plans, calculations, specifications). Pre-application meetings with Authority Having Jurisdiction. Resolution of plan review comments. Permit issuance before mobilization.

Competitor approach: Apply after contract award. Wait 4-6 weeks for review and approval. Installation delayed waiting for permit.

48Fire advantage: Permits in-hand at mobilization. No waiting.

Inspection Scheduling

Inspections scheduled 2-3 weeks in advance:

Coordinate with project schedule milestones. Confirm inspector availability. Provide required notice (48-72 hours typical). Prepare required documentation. Verify prerequisites completed (other trades’ work).

Example: Sprinkler rough-in inspection requires ceiling open, pipe installed and supported, heads installed, pressure testing complete. Inspection scheduled for Day 16 during planning phase. Confirmation call to inspector Day 13. Inspector arrival Day 16 as scheduled—no waiting for available inspection slots.

Inspector Relationship Management

48Fire maintains relationships with inspectors across service territories:

Regular communication on standard practices. Understanding of inspector preferences and priorities. Reputation for quality work and complete documentation. Track record enabling efficient inspections.

Benefit: Inspectors familiar with 48Fire work require less explanation and verification. Inspections complete faster (2-3 hours versus full-day inspections). Inspector confidence reduces re-inspection likelihood.

—

Problem Resolution Framework

Despite planning, unexpected problems occur. Resolution speed determines whether problems become delays.

48Fire’s escalation protocol:

Field-Level Resolution (Target: Same Day)

Foreman authorized to resolve minor issues:

Material substitutions (equivalent products from approved manufacturers). Minor routing adjustments (maintaining hydraulic adequacy). Coordination adjustments with other trades. Installation sequence modifications.

Authority limits: Foreman decisions can’t affect system hydraulics, change approved submittals, or violate code requirements. Within those limits, foreman has authority making decisions without escalation delays.

Project Manager Resolution (Target: 24 Hours)

Issues exceeding foreman authority escalate to project manager:

Design modifications affecting hydraulics. Submittal changes requiring re-approval. Schedule modifications affecting other trades. Cost impacts requiring change orders.

Response protocol: Project manager responds within 2 hours. Decision or escalation within 24 hours. Written documentation to all stakeholders.

Engineering Resolution (Target: 48 Hours)

Issues affecting structural adequacy or code compliance escalate to engineer:

Hydraulic recalculations for major modifications. Code interpretation questions. Alternative design approaches for unforeseen conditions. Coordination with design team on owner-furnished systems.

Response protocol: Engineer responds same business day. Analysis completed within 48 hours. Written determination with supporting calculations.

Owner/Architect Resolution (Target: 1 Week)

Issues affecting project scope, cost, or design intent involve owner and architect:

Major design changes affecting other systems. Scope additions requiring budget modifications. Code compliance alternatives requiring owner acceptance.

Response protocol: 48Fire prepares analysis with alternatives and costs. Meeting scheduled within 3 days. Decision documented within 7 days.

Key principle: Fast escalation to appropriate decision-maker. No delays waiting for authority to make decisions.

—

The Numbers Behind 200 On-Time Projects

Project types completed:

Office buildings: 87 projects

Retail centers: 34 projects

Healthcare facilities: 26 projects

Educational facilities: 18 projects

Industrial/manufacturing: 22 projects

Residential multi-family: 13 projects

Average project duration: 6.2 weeks (from mobilization to final inspection)

Longest project: 18 weeks (large hospital with complex phasing)

Shortest project: 10 days (small tenant improvement)

Schedule accuracy: 98% of projects completed within +/- 3 days of original schedule

Change order impact on schedule: 4% of projects had change orders affecting scope. Average schedule impact: 4 days. All schedule changes coordinated during weekly meetings—no surprise delays.

Material delay incidents: Zero. All materials confirmed available before installation scheduling.

Trade coordination conflicts: 11 conflicts requiring coordination resolution (5.5% of projects). Average resolution time: 2.3 hours. No conflicts caused full-day delays.

Inspection-related delays: Zero failed final inspections. 2.5% of projects had inspector scheduling changes requiring date adjustments—accommodated within overall schedule with no project delay.

—

Cost Impact of Schedule Reliability

Direct savings to building owners:

No extended general contractor supervision. No acceleration costs from compressed schedules. No occupancy delays affecting lease revenue. No financing cost extensions.

Average savings per project: $8,000-$15,000 (varies by project size)

48Fire competitive advantage:

Contractors value subcontractors providing schedule certainty. Repeat business from general contractors trusting timeline commitments. Premium pricing justified by reliability value. Reduced bid contingencies (uncertainty costs).

Owner satisfaction metrics:

Post-project surveys show 96% satisfaction with schedule performance. 89% of building owners use 48Fire on subsequent projects. 76% of projects generate referrals to other owners.

—

Key Takeaways

48Fire completed 200 consecutive fire sprinkler installations on schedule through systematic front-loaded planning beginning 6 weeks before installation starts. Design verification, materials procurement, and installation planning occur before mobilization eliminating “unforeseen conditions” discovered during construction.

Trade coordination protocols including pre-construction meetings, daily coordination huddles, and shared 3D models prevent conflicts causing schedule delays. Materials management system with pre-installation verification, just-in-time delivery, and digital tracking ensures material availability without delays.

Quality verification through daily inspections, weekly engineer reviews, and pre-inspection audits prevents rework consuming double time. Permitting and inspection coordination with early permit applications and scheduled inspections eliminates waiting for approval or available inspection slots.

Problem resolution framework with clear escalation paths and authority levels enables fast decisions preventing delays from awaiting approvals. Result: 98% schedule accuracy, zero material delays, zero failed final inspections, and zero trade coordination conflicts causing full-day delays across 200 projects.

—