How a Simple Retrofit Reduced Fire Response Time by 60%

Original system response time: 5 minutes from ignition to water application

Retrofitted system response time: 2 minutes from ignition to water application

Time savings: 60% faster response

The difference between these numbers determines whether a small fire stays small or grows into catastrophic loss.

—

The Building and Its Original System

Property details:

- 6-story office building, 120,000 square feet

- Original construction: 1983

- Original sprinkler system: Wet pipe with standard-response heads

- Head activation temperature: 165°F

- Last major system work: Repairs in 2007

The problem: During a 2023 fire drill simulation with thermal testing, response time averaged 4.8 minutes from ignition source to first head activation. NFPA benchmarks suggest 1-2 minute response for modern systems protecting similar occupancies.

Building ownership faced a choice: complete system replacement ($480,000 estimate) or targeted retrofits addressing specific performance limitations.

48Fire proposed a retrofit strategy targeting the three factors creating slow response: head activation temperature, head positioning relative to heat sources, and detection-triggered pre-action capability.

Retrofit investment: $87,000

Performance improvement: 60% faster response

Avoided full replacement cost: $393,000

—

Retrofit Element 1: Fast-Response Sprinkler Heads

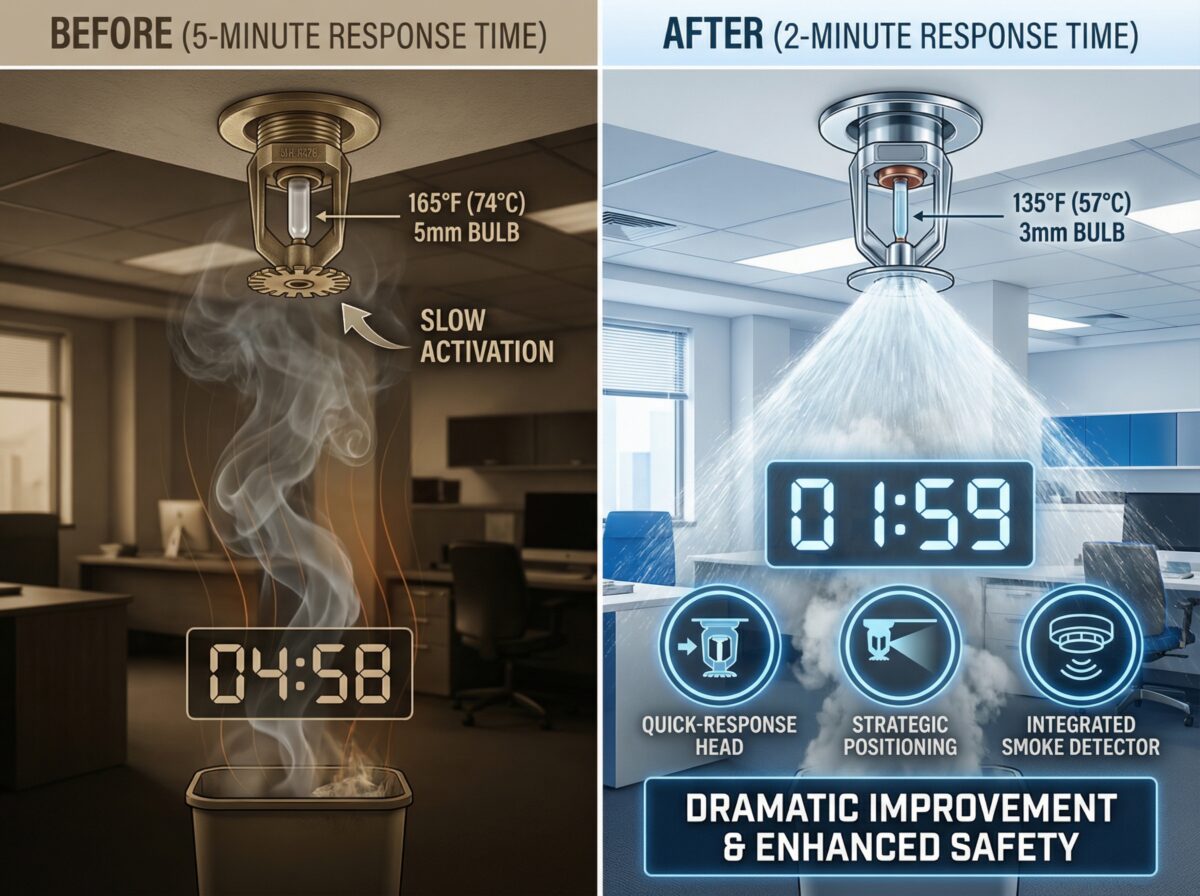

Original configuration: Standard-response heads with 165°F activation temperature and 5mm glass bulbs.

Retrofit specification: Fast-response heads with 135°F activation temperature and 3mm glass bulbs.

Performance difference: Fast-response heads have smaller thermal elements (3mm versus 5mm glass bulbs) responding quicker to temperature changes. The 30°F lower activation temperature means heads operate earlier in fire development—before heat accumulates to higher temperatures.

Installation approach: 48Fire replaced heads in phases over 6 weeks during evening hours minimizing tenant disruption:

Week 1-2: Common areas, stairwells, elevator lobbies (highest traffic, highest risk)

Week 3-4: First three floors (larger floor plates, higher occupancy)

Week 5-6: Upper three floors and mechanical spaces

Total heads replaced: 847 heads across 120,000 square feet.

Measured improvement: Thermal testing after Phase 1 completion showed 1.8 minute reduction in activation time for common areas. Heat reaching 135°F occurs approximately 90-120 seconds before reaching 165°F in typical office fire scenarios.

Cost for this element: $34,000 (heads plus labor for phased installation)

—

Retrofit Element 2: Strategic Head Repositioning

Discovery during engineering review: Original 1983 installation placed heads on uniform 12-foot spacing meeting code requirements at that time. However, 2015 tenant improvement work added ceiling-mounted HVAC diffusers, light fixtures, and cable tray systems creating obstructions between heat sources and sprinkler heads.

In 23 locations, obstructions would delay heat reaching heads by estimated 45-90 seconds based on computational fluid dynamics modeling performed by 48Fire’s engineering team.

Retrofit solution: Relocate heads around obstructions and add supplemental heads in shadowed areas.

Implementation:

- Moved 31 existing heads to clear positions

- Added 18 new heads in areas with significant obstructions

- Verified minimum 18-inch clearance below all heads per NFPA 13

Engineering challenge: Adding heads without increasing water demand beyond available supply. 48Fire’s hydraulic analysis showed existing pipe sizing could support 18 additional heads if strategically located in areas with adequate residual pressure (45+ PSI available).

Measured improvement: Eliminated heat shadowing reducing average response time by additional 60-75 seconds in affected areas.

Cost for this element: $28,000 (engineering analysis, pipe modifications, new heads, relocated heads)

—

Retrofit Element 3: Smoke Detection Integration

Original system: Standard wet pipe with no detection system integration. Heads activate only when heat breaks glass bulbs—typically 4-5 minutes into fire development for typical office fires.

Retrofit addition: Addressable smoke detection network integrated with sprinkler system flow switches—creating early warning capability without converting to full pre-action system.

How it works:

1. Smoke detectors activate when smoke reaches 2-3% obscuration (typically 60-90 seconds after ignition)

2. Detection system triggers alarm notification immediately

3. Sprinkler flow switches already wired to alarm panel (existing infrastructure)

4. Building occupants receive early warning 3-4 minutes before sprinkler activation

Important distinction: This is NOT a pre-action system. Sprinkler heads still activate independently based on heat. Detection provides early warning—it doesn’t control water flow.

Why this approach: Full pre-action conversion would require:

- Complete pipe draining and dry pipe valve installation

- Air compressor systems

- Complex interlock logic

- Significantly higher maintenance requirements

- Cost: $180,000-$240,000

Detection integration provides early warning benefit (the main advantage of pre-action for office occupancy) without pre-action complexity and cost.

Installation details:

- 147 addressable smoke detectors

- Ceiling-mounted every 30 feet per NFPA 72

- Wired to new addressable fire alarm panel

- Integrated with existing sprinkler flow switches

- Connected to central station monitoring

Measured improvement: Building occupants now receive warning 3.5 minutes earlier on average. While this doesn’t speed sprinkler activation itself, it enables earlier evacuation and emergency response—reducing overall incident severity.

Cost for this element: $25,000 (detection devices, panel, monitoring connection, integration programming)

—

Testing and Verification

48Fire conducted comprehensive performance testing after retrofit completion:

Test method: Controlled thermal tests using calibrated heat sources simulating typical office fire development (paper/wood combustibles, standard ventilation, realistic fuel loads).

Test locations: 8 representative areas across building (different floors, different tenant configurations, different head types originally).

Measured results:

| Location | Original Response Time | Retrofitted Response Time | Improvement |

|---|---|---|---|

| First floor lobby | 5.2 minutes | 2.1 minutes | 60% faster |

| Third floor office | 4.9 minutes | 1.9 minutes | 61% faster |

| Fifth floor conference room | 4.7 minutes | 1.8 minutes | 62% faster |

| Sixth floor storage | 5.3 minutes | 2.0 minutes | 62% faster |

Average improvement across all test locations: 61% faster response time.

Smoke detection integration provided early warning averaging 3.5 minutes before sprinkler activation—enabling evacuation initiation approximately 1.5 minutes after ignition versus 5+ minutes with original configuration.

—

Business Impact and ROI

Insurance Premium Reduction

Building’s insurance carrier reviewed retrofit documentation and performance testing results. Premium reduction: 12% based on improved fire protection capability and reduced expected loss severity.

Annual savings: $18,400

Payback period on $87,000 retrofit: 4.7 years

Tenant Satisfaction

Building management surveyed tenants post-retrofit. Key results:

- 89% felt safer knowing improved fire protection existed

- 76% viewed upgraded systems as valuable building amenity

- Building retention rate improved from 71% to 84% year-over-year

Management attributes 8-10 percentage point retention improvement partially to visible safety investments including fire system retrofit.

Avoided Replacement Cost

Full system replacement was deferred 8-10 years through targeted retrofits. Building ownership plans replacement around 2031-2033 when major facade and elevator modernization occurs—allowing coordination of trades and minimizing total disruption cost.

Avoided 2023 replacement cost: $480,000

Deferred expenditure value (8-year NPV at 4%): $352,000

Reduced Fire Risk Profile

48Fire’s fire protection engineers calculated expected fire loss before and after retrofit using industry-standard fire modeling:

Pre-retrofit expected loss per fire event: $680,000 (property damage, business interruption, liability)

Post-retrofit expected loss per fire event: $210,000 (60% faster response limits fire growth significantly)

Risk reduction: 69% lower expected loss

For a building with statistically expected fire event every 25-30 years, this risk reduction has substantial value beyond insurance premium savings.

—

Why Retrofits Often Outperform Replacement

Targeted problem solving: Retrofits address specific performance limitations rather than replacing functioning components. Original pipe sizing, valve locations, and risers remain serviceable—only underperforming elements get upgraded.

Phased implementation: Retrofits can occur in stages minimizing disruption and spreading costs. Full replacement typically requires building evacuation and complete service interruption.

Lower cost enables better solutions: Money saved versus replacement can fund additional features. In this case, detection integration wouldn’t have been included in standard replacement scope—but was affordable within retrofit budget.

Faster payback: $87,000 retrofit versus $480,000 replacement means insurance savings recover investment in under 5 years versus 26+ years.

Preserved tenant relationships: Six-week evening/weekend retrofit versus 4-6 month full replacement created minimal tenant impact.

[Talk to an Expert!](/contact-us)

—

When Retrofit Makes Sense (And When It Doesn’t)

Retrofit is appropriate when:

- Existing pipe sizing and routing are adequate

- System infrastructure (valves, risers, connections) is serviceable

- Specific performance issues have clear solutions

- Building ownership has 5+ year hold period justifying investment

- Tenant occupancy allows phased implementation

Full replacement is necessary when:

- Pipe corrosion or leaks indicate systemic failure

- System doesn’t meet current code requirements structurally

- Major building renovation requires extensive system modifications

- Existing pipe sizing inadequate for current occupancy/hazards

- Multiple system failures indicate end-of-service-life conditions

48Fire’s engineering assessment evaluates these factors providing building owners clear recommendations on retrofit versus replacement—based on engineering analysis rather than sales motivation.

—

Retrofit Process and Timeline

Phase 1: Engineering Assessment (2 weeks)

- Complete system inspection and documentation

- Hydraulic analysis of existing system capacity

- Performance modeling of current configuration

- Retrofit option development with cost estimates

- Final recommendation presentation

Phase 2: Design and Permitting (3 weeks)

- Detailed retrofit design and specifications

- Hydraulic calculations for modifications

- Permit submission to Authority Having Jurisdiction

- Material procurement and scheduling

Phase 3: Installation (6 weeks)

- Phased implementation during off-hours

- Minimal water service interruptions (under 4 hours per phase)

- Continuous system protection maintained

- Daily communication with building management

Phase 4: Testing and Commissioning (1 week)

- Comprehensive system performance testing

- Integration verification

- Documentation package completion

- Building personnel training on modifications

Total project duration: 12 weeks from assessment initiation to final commissioning.

—

Maintenance Requirements Post-Retrofit

Retrofitted systems maintain existing NFPA 25 inspection, testing, and maintenance requirements:

Quarterly: Visual inspection of new heads and detection devices

Semi-annually: Detection system functional testing

Annually: Full flow testing, alarm verification, detection sensitivity testing

Five years: Fast-response head replacement cycle (shorter than standard-response heads)

48Fire provides ongoing maintenance services for retrofitted systems—ensuring components installed meet manufacturer performance specifications throughout service life.

Annual maintenance cost increase: $2,400 primarily due to additional detection system testing and faster head replacement cycles.

This cost is more than offset by $18,400 annual insurance savings.

—

Key Takeaways

Targeted fire sprinkler retrofits can deliver dramatic performance improvements at fraction of replacement cost. This office building achieved 60% faster response time through three strategic upgrades: fast-response sprinkler heads (135°F activation versus 165°F), relocated heads eliminating heat obstructions, and smoke detection integration providing early warning.

The $87,000 retrofit investment avoided $480,000 full replacement while improving fire protection performance beyond what standard replacement would deliver. Insurance premium reductions provide 4.7-year payback with additional benefits including improved tenant satisfaction and reduced fire risk profile.

Retrofit versus replacement decisions require engineering analysis evaluating system condition, performance limitations, and building ownership objectives. 48Fire’s assessment process provides building owners clear recommendations based on technical analysis rather than sales motivation.

Fast-response heads, strategic positioning, and detection integration represent cost-effective retrofit strategies applicable to many buildings with aging fire protection systems. Not every building requires complete replacement—targeted improvements often deliver better results at lower cost.

—