What Every Business Should Know About NFPA 25 & 72

Two separate fire protection standards govern two separate systems. Yet most businesses treat them as disconnected requirements managed by different vendors, scheduled independently, and tracked using separate documentation systems.

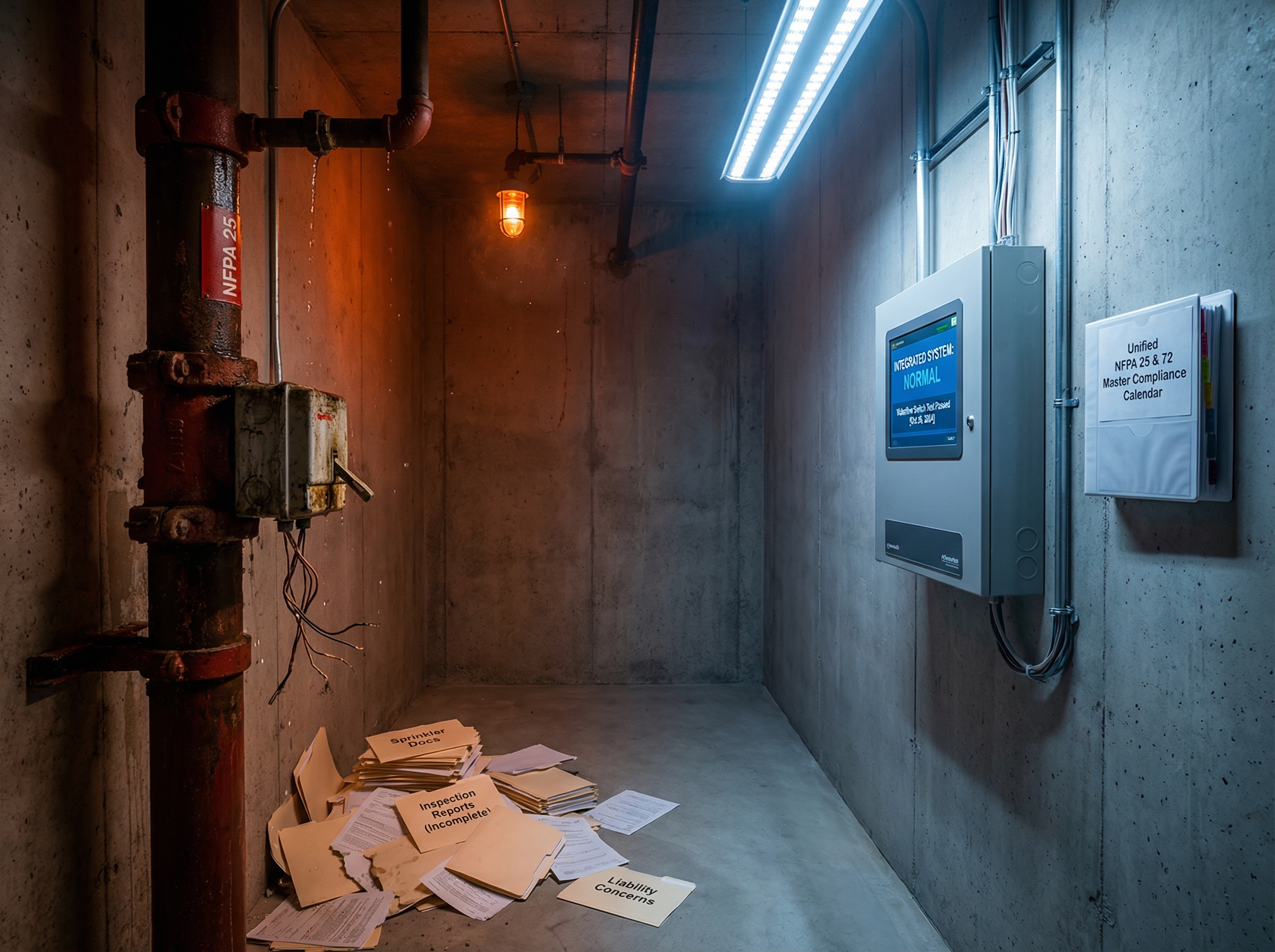

This fragmented approach creates compliance gaps, missed inspections, documentation failures, and—worst case—a facility where systems designed to work together operate in isolation.

NFPA 25 manages sprinkler system testing and maintenance. NFPA 72 manages fire alarm system testing and monitoring. But in real emergencies, these systems must coordinate perfectly. A sprinkler that flows water needs an alarm that alerts occupants. An alarm that sounds needs a sprinkler system ready to suppress the fire. When each standard is followed independently without connection, the result is reduced effectiveness and increased liability.

Understanding how NFPA 25 and NFPA 72 work together—and how to manage both under one compliance framework—separates facilities that pass inspections from those facing repeated violations.

—

The Two Standards: Separate Requirements, Connected Outcomes

NFPA 25: Sprinkler System Testing and Maintenance

NFPA 25 requires fire sprinkler systems to be inspected weekly, monthly, quarterly, annually, and every 5 years, with testing frequencies including quarterly testing of main drain and mechanical alarm devices, semi-annual testing of vane and pressure switch type devices, and annual comprehensive system tests. These requirements apply differently based on sprinkler system type (wet pipe, dry pipe, pre-action, deluge) and local authority adoption.

What NFPA 25 actually requires:

Wet pipe systems (most common in heated areas) must receive monthly gauge and alarm valve inspections plus quarterly water flow alarm tests. Dry pipe systems (used in unheated areas) require weekly control valve and gauge inspections plus quarterly water flow alarm testing using the bypass connection—never by opening the inspector’s test connection, which risks system activation and freeze damage.

The annual comprehensive test is where most violations occur. Annual testing includes inspection of the facility’s supply of spare sprinkler heads to ensure a minimum of two sprinklers of each type and temperature rating, plus a sprinkler wrench for each type. Most facilities maintain neither, creating immediate violations during inspections.

Every 5 years, NFPA 25 requires internal pipe inspection documenting obstruction, corrosion, or sediment. NFPA 25 recommends replacing standard sprinkler heads every 50 years, while fast-response heads have a 20-year testing requirement to maintain effectiveness. If sprinkler heads exceed age limits, they must be tested at a certified lab or replaced.

NFPA 72: Fire Alarm Testing and Monitoring

NFPA 72 requires fire alarm systems in most commercial buildings, with specific testing and documentation mandates. Smoke detectors require annual sensitivity testing. Heat detectors require annual temperature activation tests. Notification devices require annual sound level measurement (minimum 75 dB at all locations). Pull stations require annual mechanical operation testing.

The integration point: Sprinkler waterflow switches must be monitored by fire alarm systems. When a sprinkler activates and water flows, the waterflow switch triggers the fire alarm. This connection means a sprinkler system can’t operate independently—it must integrate with a monitored fire alarm system.

—

Why Separate Management Creates Compliance Failures

Most facilities manage NFPA 25 and NFPA 72 compliance independently because:

Different vendors. Sprinkler contractors maintain sprinkler systems. Fire alarm companies maintain alarm systems. Each vendor operates on their own schedule, using their own documentation format, scheduling systems independently.

Different occupancy knowledge. Fire alarm technicians may not understand NFPA 25 sprinkler requirements. Sprinkler contractors may not be trained in NFPA 72 integration. When each operates separately, coordination fails.

Fragmented documentation. Sprinkler testing records stored one place. Fire alarm records stored elsewhere. During inspections, property managers scramble to locate scattered documentation, often unable to prove compliance within required timeframes.

Scheduling conflicts. One contractor schedules annual testing in March. The other in August. A facility might have June inspections where systems aren’t documented as current, creating violations even though testing technically occurred.

Missed integration testing. NFPA 72 requires testing that waterflow switches trigger alarm signals. But if sprinkler and alarm contractors don’t coordinate, this critical test never happens. The sprinkler flows. The alarm doesn’t sound. The integration fails.

Cost multiplication. Separate contractors, separate service calls, separate documentation systems cost more than integrated compliance management.

—

The Real Consequences of Fragmented Compliance

Fire safety inspections reveal integration failures immediately.

Inspection scenario: Fire marshal arrives for annual inspection. Pulls NFPA 25 compliance records. Sees last water flow test was six months ago. Asks for current NFPA 72 fire alarm monitoring verification proving the waterflow switch triggering tested recently.

Facility manager can’t produce it. Different contractor—different date. The systems tested separately. Integration never verified.

Violation citation: “Sprinkler waterflow switch integration not documented. Cannot confirm fire alarm activation upon sprinkler flow.”

Cost: Violation fine ($500-2,000 depending on jurisdiction) plus immediate reinspection ($300-1,500 fee). Insurance premium increases due to documented violation (5-15% increase). Accelerated inspection frequency (quarterly vs. annual) until violation resolved and documented as corrected.

This scenario happens repeatedly because facilities don’t realize NFPA 25 and NFPA 72 require integrated testing and coordination, not just separate compliance.

—

Integrated Compliance: The Testing Framework That Passes Inspections

48Fire Protection manages NFPA 25 and NFPA 72 as a unified compliance system rather than separate requirements.

Monthly Coordination Check

First business day of each month: Property manager (or 48Fire Protection) performs coordinated visual inspection verifying:

- Sprinkler system control valve is in normal position (open)

- Fire alarm panel shows no trouble signals

- Sprinkler pressure gauges in green zone

- Fire alarm system showing normal operation status

Why this matters: Monthly coordination prevents either system being deactivated, isolated, or failing without immediate discovery.

Quarterly Integration Testing

January, April, July, October: 48Fire Protection performs coordinated testing:

Sprinkler side (NFPA 25 quarterly requirement):

- Water flow alarm test using main drain valve

- Alarm switch testing

- Mechanical valve testing

Fire alarm side (NFPA 72 requirement):

- Monitoring company notification that testing occurring

- Fire alarm system reset and normal operation verification

Integration verification:

- Waterflow switch signal transmitted to fire alarm panel

- Fire alarm signal received at monitoring station

- Both devices document transmission and receipt

Why integration matters: This test proves the connection works. If sprinklers flow, the alarm actually sounds and monitoring station actually alerts. Without this coordinated test, the integration remains theoretical.

Annual Comprehensive Assessment

Each year at same time: 48Fire Protection performs complete NFPA 25 + NFPA 72 evaluation:

NFPA 25 annual inspection includes:

- Spare sprinkler head inventory (minimum two each type/rating)

- Spare sprinkler wrench availability

- Backflow prevention assembly inspection

- Hangar and seismic bracing

- Signage and identification marking

- Equipment tag documentation

NFPA 72 annual testing includes:

- Smoke detector sensitivity testing at 10% sample locations

- Heat detector temperature activation testing

- Pull station mechanical operation

- Notification device sound level measurement

- Monitoring signal transmission verification

- Battery load testing

Integration assessment includes:

- Sprinkler information clearly labeled on fire alarm panel

- Waterflow switch location known and accessible

- Testing procedures documented and standardized

- All devices included in compliance schedule

Every 5 Years: Professional Internal Inspection

NFPA 25 requires very detailed and specific inspection, testing and maintenance services that need to be performed annually, and because of their complexity, these services must be performed by state licensed fire protection contractors, certified fire protection technicians and/or fire safety engineers.

This is where 48Fire Protection’s comprehensive fire safety inspections identify violations before official audits occur.

—

NFPA 25 & 72 Testing Comparison: What Gets Tested When

| Testing Task | NFPA Standard | Frequency | Performed By | Documentation Required |

|---|---|---|---|---|

| Sprinkler control valve position check | NFPA 25 | Weekly | Building staff (trained) | Visual inspection log |

| Sprinkler pressure gauge reading | NFPA 25 | Monthly | Building staff (trained) | Recorded gauge pressure |

| Water flow alarm test | NFPA 25 | Quarterly | Licensed contractor | Test certificate with date/time |

| Fire alarm control panel status | NFPA 72 | Weekly | Building staff | Maintenance log entry |

| Smoke detector sensitivity test | NFPA 72 | Annually (10% sample) | Licensed contractor | Test results with readings |

| Heat detector activation test | NFPA 72 | Annually | Licensed contractor | Test certificate |

| Waterflow switch integration test | NFPA 25 + 72 | Quarterly/Annually | Licensed contractor | Sprinkler test + alarm test records |

| Spare sprinkler inventory | NFPA 25 | Annually | Building staff | Inventory list verification |

| Notification device sound test | NFPA 72 | Annually | Licensed contractor | Decibel readings at locations |

| Backflow assembly inspection | NFPA 25 | Annually | Licensed contractor | Certification of inspection |

| Sprinkler head age assessment | NFPA 25 | Every 5-10 years | Licensed lab (if testing) | Testing report or replacement certification |

—

Documentation: The Compliance Proof That Inspectors Want

Fire marshals don’t accept verbal assurance. They review written documentation proving compliance occurred.

NFPA 25 documentation required:

- Weekly/monthly inspection logs with dates and observations

- Quarterly water flow test certificates with time, date, pressure readings

- Annual comprehensive inspection checklist completed

- Spare parts inventory lists

- Five-year internal inspection report (pipe obstruction, corrosion assessment)

- Repair/replacement records when deficiencies corrected

NFPA 72 documentation required:

- Monthly fire alarm system operation logs

- Annual sensitivity testing results (smoke detector readings)

- Heat detector activation temperatures recorded

- Sound level measurement printouts (dB readings at locations)

- Monitoring company signal transmission confirmations

- Battery load test results

Integration documentation required:

- Waterflow switch testing coordinated with fire alarm testing

- Sprinkler system information clearly noted on fire alarm panel

- Testing procedures showing both systems included

- Monitoring station acknowledgment that waterflow switch signals received correctly

Best practice: 48Fire Protection creates centralized documentation combining all testing into one master compliance calendar. Every task, test, and required inspection appears with assigned responsibility, schedule, and documentation location. This approach eliminates the scattered records that create violations during inspections.

—

Common NFPA 25 & 72 Violations Found During Fire Safety Inspections

Incomplete water flow testing. Facilities test the alarm valve but don’t document the waterflow switch triggering the fire alarm. Violation: Integration not verified.

Missing annual comprehensive test. Facilities perform monthly/quarterly tasks but skip the comprehensive annual inspection. Violation: Non-compliance with NFPA 25 Section 8.

No spare parts inventory. Facilities don’t maintain minimum two sprinklers of each type/rating. Violation: Cannot service system during emergencies.

Outdated detection testing. Facilities test smoke detectors but fail to document sensitivity (actual readings in percentages). Violation: Cannot prove devices within operational parameters.

Separated documentation. Sprinkler records in one file. Fire alarm records elsewhere. During inspection, property managers can’t locate documents showing current compliance. Violation: Failure to maintain required records.

No integration verification. Waterflow switch tested separately from alarm system. No documentation proving signal transmission successful. Violation: Fire alarm monitoring not verified for sprinkler activation.

Pressure gauge not calibrated. Facilities read sprinkler system pressure gauge but never calibrate it. Violation: Readings not reliable for compliance assessment.

Extended testing intervals. Facilities assume they can extend quarterly tests to semi-annual or annual based on past performance. Violation: NFPA 25 frequency requirements mandatory regardless of history.

—

How 48Fire Protection Prevents NFPA 25 & 72 Violations

48Fire Protection consolidates both standards into one compliance framework ensuring:

Coordinated scheduling where quarterly sprinkler water flow tests occur same day as fire alarm integration testing, preventing separate dates and documentation gaps.

Integrated documentation combining all NFPA 25 and NFPA 72 testing into centralized records accessible during inspections in seconds rather than hours of searching scattered files.

Unified testing procedures where both systems tested together verifying the connection works—waterflow switch triggers fire alarm signal transmitted to monitoring station—rather than testing components independently.

Automated compliance tracking where monthly, quarterly, and annual requirements appear on single master schedule with automated reminders preventing missed testing cycles.

Professional assessment identifying violations before official inspections occur, providing time to correct issues without violation citations appearing on permanent inspection records.

Staff training ensuring building personnel understand both NFPA 25 and NFPA 72 responsibilities, weekly/monthly checks they perform, and escalation procedures when deficiencies appear.

—

Moving Forward: Unified Compliance Strategy

Your facility probably has two separate fire protection systems operating independently, tested by different contractors, documented separately, and managed without integration.

The most compliant facilities—those passing fire safety inspections without violations—manage NFPA 25 and NFPA 72 as one unified compliance system. Sprinkler testing and fire alarm testing occur on coordinated schedules. Documentation consolidates all records into one master file. Integration testing verifies both systems work together rather than independently.

48Fire Protection helps facilities transition from fragmented to integrated compliance management. We manage sprinkler system testing (NFPA 25), fire alarm system testing (NFPA 72), and integration verification ensuring both systems coordinate properly during emergencies.

The result: fire safety inspections that reveal zero violations, continuous compliance throughout the year, and the assurance that when fire emergencies occur, both your sprinkler and fire alarm systems activate correctly together protecting occupants and property.

—

Take Action: Schedule Your NFPA 25 & 72 Compliance Assessment

If your facility manages sprinkler and fire alarm compliance separately, you’re missing integration verification and creating compliance gaps that inspectors discover.

[Talk to an Expert!](/contact-us) at 48Fire Protection about consolidating NFPA 25 and NFPA 72 testing into one unified compliance framework. We’ll assess your current systems, identify integration gaps, coordinate all testing requirements, and establish unified documentation that passes fire safety inspections without violations.

Your building’s sprinkler and fire alarm systems were designed to work together. Your compliance management should too.