The Role of Fire Safety Inspections in Multi-Site Fire Protection

When One Facility’s Problem Becomes a Network Threat

A company operated five office facilities across different states. A fire started in a stairwell at one facility—the secondary evacuation route at a second facility. Occupants at the second facility faced compromised exits because a fire three buildings away created smoke that traveled through shared systems the company didn’t know existed.

The incident revealed something critical: the company wasn’t managing five separate fire risks. It was managing one interconnected network of risks where a problem at one facility could cascade into consequences at multiple facilities.

After the incident, the company implemented a multi-site fire safety inspection program. What they discovered changed how they understood fire protection: single-location inspections miss the cascading risks that only become visible when you assess all locations simultaneously.

—

The Hidden Cascade: How Single-Facility Problems Create Network Consequences

Every facility operating independently assumes its fire protection stands alone. In reality, networks of facilities create hidden consequences that single-site thinking cannot detect.

Cascade Example 1: The Backup Battery Timeline Cascade

Facility A: 45,000 sq ft, 8 years old

- Backup batteries installed 8 years ago

- Manufacturer specification: 10-15 year lifespan

- Current status: 80% through lifespan, nearing replacement need

Facility B: 35,000 sq ft, 5 years old

- Backup batteries installed 5 years ago

- Manufacturer specification: 10-15 year lifespan

- Current status: 33-50% through lifespan, appears fine

Individual inspection result: “Facility A needs batteries. Facility B is fine.”

Multi-site inspection result: “Wait—all five facilities are on similar installation timeline. What happens when multiple facilities reach end-of-life simultaneously?”

The Cascade: Without coordinated visibility, management doesn’t anticipate that three facilities will need battery replacement within the same 12-month window. Result: emergency procurement rush, premium pricing, inability to schedule replacements during low-occupancy periods, potential service gaps during transition.

With coordinated inspection: Anticipate the cascade, plan procurement, coordinate scheduling, avoid emergency situations, maintain continuous protection across all facilities.

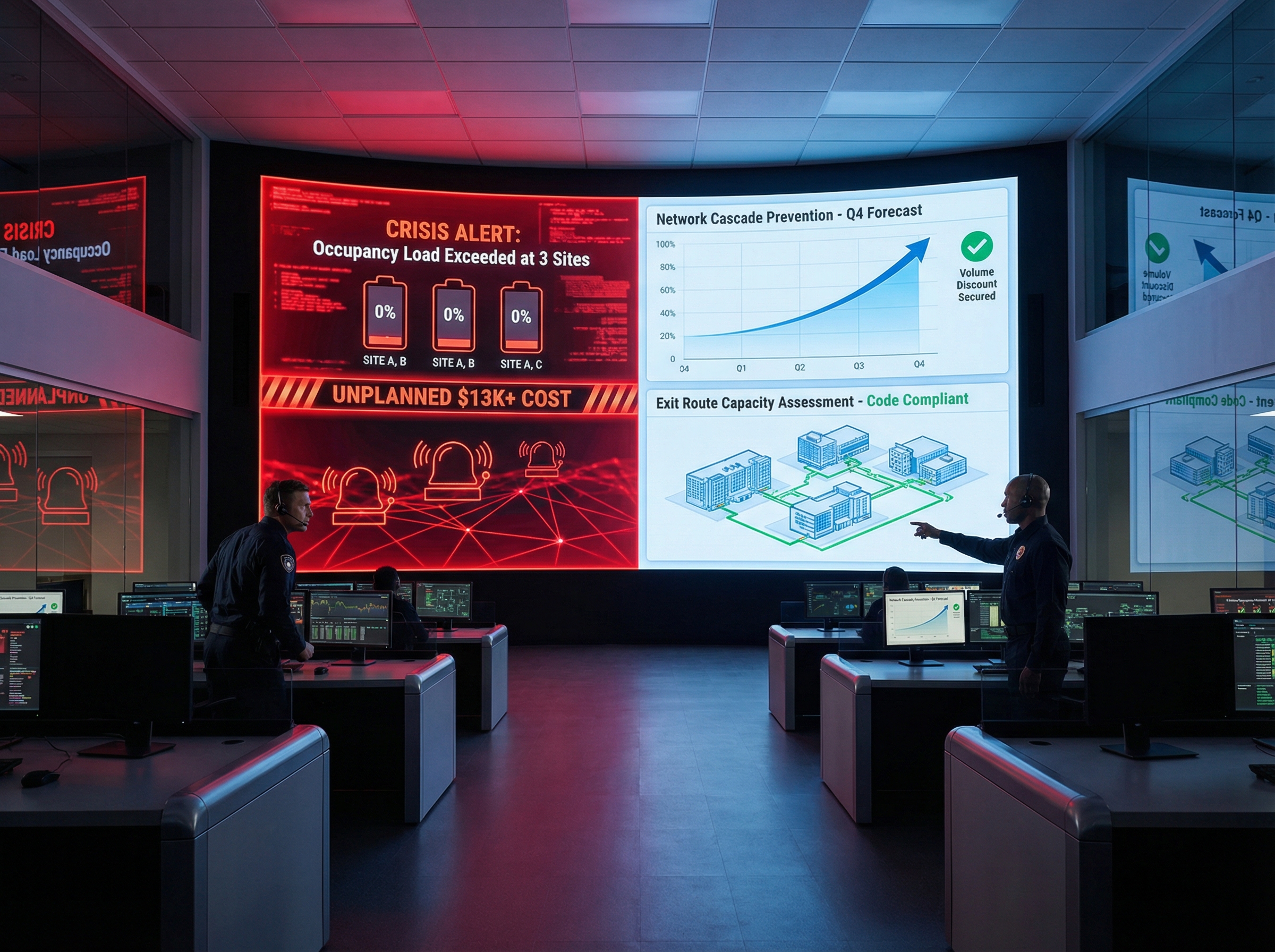

Cascade Example 2: The Occupancy Load Cascade

Facility C: 52,000 sq ft, 15 years old

- Occupancy: 300 people

- Emergency lighting minimum: 1 foot-candle

- Current status: Six areas measure 0.9 foot-candles (below minimum)

- Exit routes: Designed for 250-person occupancy

Single-site inspection: “Facility C has lighting below code in six areas. Correct them.”

Network-level question: “Is Facility C the only facility with occupancy growth? Are other facilities also at or exceeding original design occupancy?”

The Cascade: If multiple facilities have grown occupancy beyond original design, exit routes at multiple locations might be undersized. Fire spreads at Facility C, evacuation routes overflow at Facility C AND create bottleneck at shared evacuation area. Occupancy growth wasn’t a Facility C problem—it’s a network capacity problem hidden by single-site inspections.

With coordinated inspection: Discover occupancy growth across network, assess cumulative impact on shared infrastructure, implement consistent solutions, manage network-level capacity issues.

Cascade Example 3: The System Age Cascade

Facility D: 38,000 sq ft, 3 years old – Modern systems, full compliance

Facility E: 42,000 sq ft, 12 years old – Aging systems, multiple issues

Single-site inspection: “Facility D is compliant. Facility E needs corrections.”

Network consequence: “If Facility D is the benchmark for modern systems, what’s our plan when Facilities A, B, and C age to Facility E’s condition?”

The Cascade: Without network visibility, management reacts to problems at aging facilities but doesn’t anticipate systematic issues as entire facility portfolio ages. Result: reactive corrections for each facility instead of proactive portfolio strategy.

With coordinated inspection: Identify age-related failure patterns, anticipate future needs based on facility timelines, plan systematic upgrades across network rather than responding to emergencies at individual facilities.

—

The Consequence Revealed: Why Multi-Site Visibility Prevents Disasters

These cascades share a common characteristic: they’re invisible without multi-site visibility.

Single-site inspections reveal: Individual facility status

Multi-site inspections reveal: Network consequences that affect multiple facilities

Cascade Consequence 1: Procurement Vulnerability

Without multi-site visibility: Emergency procurement of batteries for multiple facilities simultaneously

- Premium pricing for expedited orders

- Inability to negotiate volume discounts

- Service installation delays

- Potential gaps in emergency lighting backup during transition

With multi-site visibility: Coordinated procurement across all facilities

- Volume discount negotiation

- Strategic scheduling minimizing facility impact

- Continuous backup coverage across all facilities

- Planned implementation

Cascade Consequence 2: Occupancy Capacity Crisis

Without multi-site visibility: Occupancy growth at individual facilities managed independently

- Exit routes at multiple facilities potentially undersized

- Evacuation bottlenecks at shared facilities

- Emergency response complicated by capacity uncertainty

With multi-site visibility: Network capacity assessment

- Identify cumulative occupancy impact

- Assess shared infrastructure capacity

- Implement consistent solutions across network

- Ensure adequate capacity at all locations simultaneously

Cascade Consequence 3: Aging Facility Strategy Gap

Without multi-site visibility: React to system failures at aging facilities

- Unexpected downtime and emergency corrections

- No anticipation of future needs

- Portfolio approaching systematic failure points

With multi-site visibility: Proactive portfolio strategy

- Identify systematic aging patterns

- Anticipate future needs based on facility age

- Plan systematic upgrades proactively

- Prevent portfolio-wide system failures

—

A Real Company: Cascade Prevention Through Multi-Site Inspection

A company operating five facilities (212,000 sq ft total) implemented coordinated multi-site fire safety inspections.

Year 1 Cascade Discoveries:

Cascade 1: Backup Battery Timeline

- All facilities except D had backup batteries approaching or at end-of-life within 12-24 months

- Without multi-site visibility: Four separate emergency replacements over 18 months

- With multi-site visibility: Coordinated replacement across all four facilities simultaneously

Cascade 2: Emergency Lighting Age Pattern

- Facilities A, C, E (all 8+ years old) had emergency lighting below code minimum

- Facility B (5 years old) and D (3 years old) were compliant

- Pattern identified: Emergency lighting systems installed 8+ years ago experiencing age-related degradation

Cascade 3: Fire Door Seal Deterioration

- Facilities C and E (oldest) had multiple fire door seal failures

- Facilities A and B showed early signs of seal deterioration

- Facility D (newest) had fully intact seals

Cascade 4: Occupancy Growth Impact

- Facility C occupancy grew from 250 to 300 (design → actual)

- Facility A occupancy grew from 200 to 240 (design → actual)

- Exit routes at multiple facilities now undersized relative to occupancy

- Without multi-site view: Individual facility problem

- With multi-site view: Network capacity issue affecting evacuation planning

Coordinated Cascade Prevention Response:

Rather than address issues facility-by-facility, multi-site program implemented network-level strategy:

Network-Wide Battery Replacement Initiative

- Year-end: Coordinate replacement across all four affected facilities

- Timing: Low-occupancy period for all facilities

- Result: Continuous backup coverage across network, volume discount, planned implementation

Emergency Lighting Standardization Program

- Identified 8+ year old systems as cascade risk

- Implemented refresh across three oldest facilities simultaneously

- Standardized on same specification across all locations

- Result: Consistent lighting standard across network, elimination of cascade risk

Exit Route Capacity Assessment

- Evaluated occupancy load at all facilities against exit capacity

- Identified undersized routes at facilities A and C

- Planned modifications ensuring adequate capacity across entire network

- Result: Network-level occupancy capacity solved proactively, not reactively

Fire Door Seal Program

- Prioritized two oldest facilities for immediate seal replacement

- Scheduled remaining facilities for seal inspection and preventive replacement

- Result: Consistent fire-rated door integrity across network

Year 1 Total Investment: $34,000 across five facilities

- Avoided Cost: Emergency procurement ($8,000+), emergency service calls ($5,000+), regulatory citations (uncalculated), evacuation compromise (incalculable)

—

The Cascade Prevention Framework

Multi-site fire safety inspections prevent cascades by enabling three critical visibility levels:

Level 1: Individual Facility Visibility

What you see in single-site inspection:

- Facility-specific issues

- Individual system status

- Location-specific compliance gaps

Level 2: Comparative Visibility

What you see in multi-site inspection:

- Which facilities have similar issues

- Age-related failure patterns across portfolio

- Occupancy trends at multiple locations

Level 3: Cascade Visibility

What you understand through multi-site analysis:

- How problems at one facility affect others

- What network consequences to anticipate

- What coordinated response prevents

Without Level 2 and 3 visibility, management reacts to consequences instead of preventing cascades.

—

Why Enterprise Management Demands Multi-Site Visibility

Companies managing single facilities think about fire protection locally: “Is this building protected?”

Companies managing multiple facilities must think about fire protection systemically: “How do risks at one location affect other locations? What consequences should we anticipate? How do we prevent cascading failures across the network?”

Multi-site fire safety inspections answer these questions. They reveal cascades that single-site inspections cannot see.

—

Multi-Site Fire Safety Inspections: Cascade Prevention Strategy

48Fire Protection conducts multi-site fire safety inspections specifically designed to identify and prevent cascades across facility networks.

Rather than conduct five separate inspections of five separate facilities, we conduct a coordinated assessment that:

Reveals Cascades

- Identifies problems at one facility that affect others

- Discovers network-level patterns

- Understands occupancy and system interdependencies

Anticipates Consequences

- Recognizes when multiple facilities face similar timeline issues

- Predicts portfolio-level risks

- Forecasts future needs across all locations

Enables Coordinated Response

- Plans network-level solutions

- Coordinates procurement and implementation

- Prevents emergency situations through planning

Provides Network Visibility

- Unified status across entire portfolio

- Clear understanding of network risk profile

- Basis for strategic decision-making

—

Your Multi-Site Network Needs Cascade Prevention

If your company operates multiple facilities, ask yourself:

- Could a problem at one facility affect others?

- Are we anticipating network-level issues or reacting to them?

- Do we have visibility into coordinated risks across all locations?

- Could we prevent cascades or are we managing consequences?

- Is our fire protection strategy facility-focused or network-focused?

If you’re uncertain about any answer, your multi-site network would benefit from coordinated multi-site fire safety inspections.

48Fire Protection helps companies operating multiple facilities identify and prevent cascades through coordinated fire safety inspection programs. Rather than managing independent facility inspections, we provide network-level visibility that reveals hidden consequences and enables proactive cascade prevention.

[Contact 48Fire Protection](/contact-us) today to discuss developing a cascade-prevention multi-site fire safety inspection program for your facility network. We’ll help you move from reactive facility management to proactive network strategy that prevents cascades before they become crises.

Fire protection at one facility is important. Fire protection across your entire network is critical.