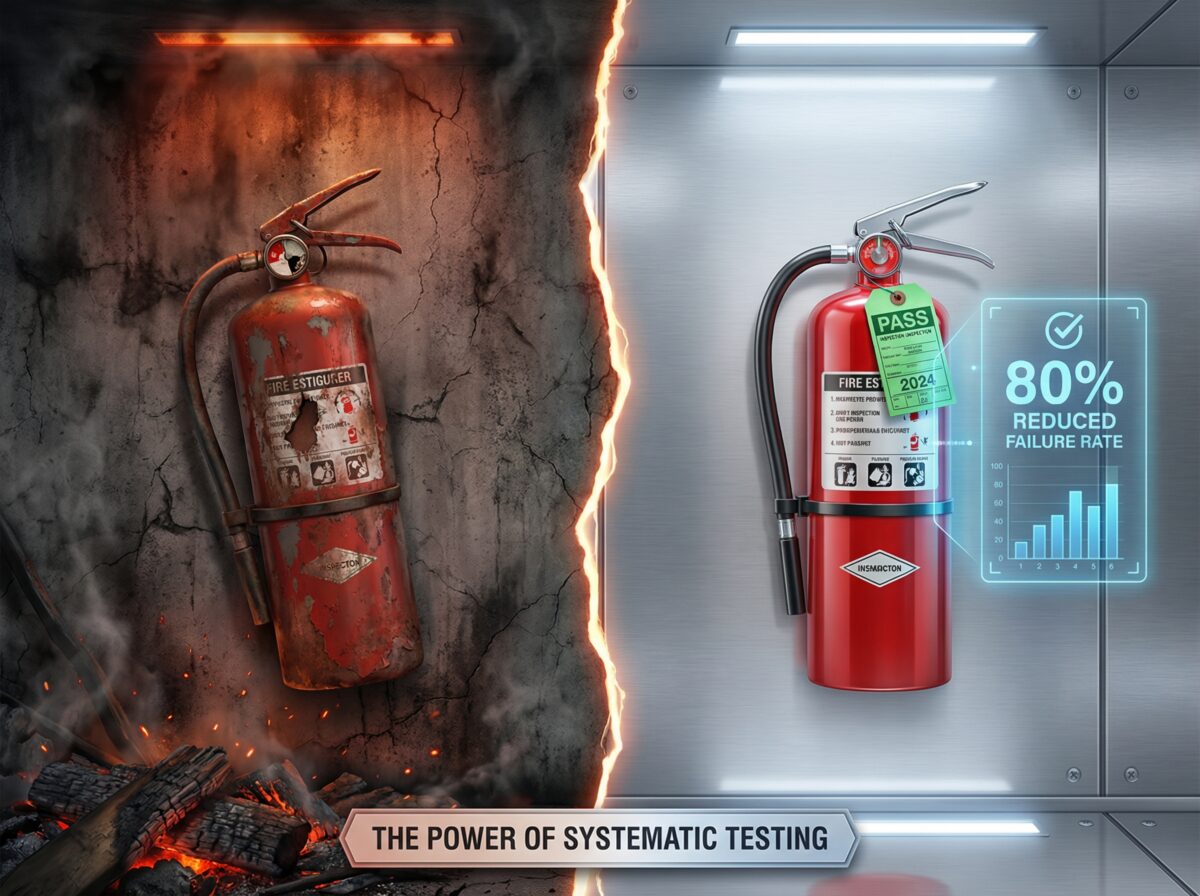

Fire Extinguisher Service That Cut Failures by 80%

Extinguisher failure rates drop when systematic testing replaces random checks.

—

EXECUTIVE BRIEF

Commercial facilities face a persistent problem: fire extinguishers that look operational but fail when needed. Equipment hangs on walls for years, appearing ready. Then fires happen, employees grab extinguishers, and nothing works—discharged units that were never recharged, corroded internals invisible from outside, pressure loss that went undetected.

The solution isn’t buying better equipment. It’s implementing fire extinguisher testing programs that verify actual function, not just appearance.

THE NUMBERS:

- Facilities with systematic testing: 4-8% equipment failure rates

- Facilities with visual-only checks: 20-40% equipment failure rates

- Reduction through professional testing: 60-80% fewer failures

This analysis examines how fire extinguisher testing transforms compliance from paperwork exercise to genuine equipment verification.

—

SECTION 1: THE TESTING GAP

What Most Facilities Actually Do

Monthly visual inspections walk past extinguishers checking obvious problems—missing equipment, damaged shells, pressure gauge readings. Annual maintenance by technicians adds slightly more rigor—seal checks, weight verification, tag replacement.

But neither process answers the critical question: Will this extinguisher actually discharge agent effectively when someone pulls the pin during a fire?

Visual inspection can’t determine:

- Whether internal corrosion has compromised the pressure vessel

- If the discharge valve mechanism functions properly under pressure

- Whether the siphon tube inside remains intact and properly positioned

- If the extinguishing agent has degraded or become contaminated

- Whether the hose (on wheeled units) maintains pressure integrity

Annual maintenance improves verification but still relies heavily on external assessment and gauge readings rather than functional testing.

What Fire Extinguisher Testing Reveals

Hydrostatic testing—the primary method for verifying extinguisher integrity—involves pressurizing the empty vessel to levels exceeding normal operating pressure. Units that pass demonstrate they can safely contain the pressures needed for proper discharge. Units that fail show weaknesses invisible during visual inspection.

The testing schedule from NFPA 10:

| Extinguisher Type | Hydrostatic Test Interval |

|---|---|

| Carbon dioxide, Water, Foam | 5 years |

| Dry chemical (stored pressure, steel/brass/aluminum) | 12 years |

| Halogenated agent, Clean agent | 12 years |

Internal examination during six-year maintenance for stored pressure units provides another verification point—technicians actually open the extinguisher and inspect components directly.

These testing requirements exist because visual inspection and basic maintenance cannot reliably detect all failure modes.

48Fire provides complete fire extinguisher testing services including hydrostatic testing, internal examinations, and functional verification that identifies problems before equipment fails during actual emergencies.

Case Study Framework: 80% Reduction

Consider facilities implementing systematic fire extinguisher testing programs versus those using visual inspection only.

Facility profile: 200-unit commercial property, mixed extinguisher types (ABC dry chemical, CO2, water), typical 10-year equipment age range.

Before systematic testing (visual inspection only):

- Units tested during first comprehensive program: 200

- Units failing hydrostatic testing: 48

- Units with internal corrosion requiring replacement: 34

- Units with valve/component failures: 22

- Total failures identified: 104 units (52% failure rate)

After implementing systematic testing (annual audits + scheduled hydrostatic testing):

- Annual internal examination catches early degradation

- Scheduled hydrostatic testing occurs before major failures develop

- Equipment nearing test intervals receives proactive replacement consideration

- Current failure rate in subsequent testing cycles: 8-12 units (4-6% failure rate)

Failure reduction: 80-85% through systematic fire extinguisher testing

The difference isn’t equipment quality—it’s verification rigor identifying and addressing problems before they become critical failures.

—

SECTION 2: UNDERSTANDING TESTING REQUIREMENTS

NFPA 10 Testing Standards

Fire extinguisher testing requirements vary by equipment type, reflecting different failure modes and risk profiles.

#

Hydrostatic Testing

Hydrostatic testing verifies pressure vessel integrity by filling the extinguisher with water (or other non-compressible fluid) and subjecting it to pressure exceeding normal operating levels.

Test pressure specifications:

- Typically 1.5 to 3 times normal operating pressure

- Varies by extinguisher type and construction

- Must be performed using calibrated test equipment

- Requires trained technicians with proper facilities

What the test detects:

- Cracks or stress fractures in pressure vessels

- Corrosion that has weakened shell integrity

- Weld failures or seam defects

- Any condition that could cause rupture during normal use

Units failing hydrostatic testing must be destroyed and replaced—they cannot be repaired for continued service as pressure vessels.

#

Internal Examination

Stored pressure extinguishers undergo internal examination during six-year maintenance. This involves:

Complete disassembly:

- Removal of valve assembly

- Emptying of extinguishing agent

- Internal visual inspection of shell

- Component inspection and testing

- Cleaning and reassembly

- Recharge with fresh agent

What internal examination detects:

- Internal corrosion not visible externally

- Agent contamination or degradation

- Siphon tube damage or displacement

- Valve component wear or malfunction

- Seal degradation

Internal examination provides verification impossible through external inspection alone.

48Fire maintains certified testing facilities with calibrated equipment and trained technicians qualified to perform both hydrostatic testing and internal examinations meeting all NFPA 10 requirements.

OSHA Testing Requirements

OSHA regulation 1910.157 reinforces NFPA testing standards, requiring employers to ensure portable fire extinguishers are maintained per manufacturer recommendations and applicable standards.

Key OSHA requirements:

- Extinguishers must be inspected when initially placed in service

- Visual inspection required monthly

- Annual maintenance by qualified persons

- Testing per NFPA 10 schedules

- Removal from service of any extinguisher showing defects

OSHA citations for inadequate fire extinguisher testing typically fall under serious violations ($15,625 penalty) when deficient equipment creates hazardous conditions.

Testing vs. Inspection vs. Maintenance

Understanding these distinct activities prevents compliance gaps.

MONTHLY INSPECTION:

- Who: Trained facility staff or professional services

- What: Visual verification of accessibility, pressure, physical condition

- Tools: Visual observation only

- Documentation: Date, inspector, findings

- Purpose: Catch obvious problems quickly

ANNUAL MAINTENANCE:

- Who: Certified technicians

- What: Detailed examination, component verification, seal replacement

- Tools: Specialized equipment, manufacturer manuals

- Documentation: Service tags, detailed records

- Purpose: Verify proper function and catch developing issues

HYDROSTATIC TESTING:

- Who: Certified technicians with testing facilities

- What: Pressure vessel integrity verification

- Tools: Hydrostatic test equipment, pressure pumps, calibrated gauges

- Documentation: Test records, pass/fail determination

- Purpose: Ensure pressure vessel safety under actual operating conditions

INTERNAL EXAMINATION:

- Who: Certified technicians

- What: Complete disassembly and internal inspection

- Tools: Appropriate tools, inspection equipment, cleaning materials

- Documentation: Component condition records, service documentation

- Purpose: Verify internal condition and agent quality

All four activities are required. None substitutes for the others.

—

SECTION 3: TESTING METHODOLOGIES

Hydrostatic Testing Process

Professional fire extinguisher testing follows specific procedures ensuring accurate results and technician safety.

STEP 1: Pre-test preparation

- Complete discharge of extinguishing agent

- Removal of valve assembly and internal components

- Initial internal inspection for obvious defects

- Cleaning of internal surfaces

- External inspection for damage that would invalidate test

STEP 2: Test setup

- Installation of test plug or closure

- Connection to hydrostatic test pump

- Placement in protective testing enclosure (safety requirement)

- Gauge installation for pressure monitoring

STEP 3: Pressurization

- Fill with water to eliminate air pockets

- Gradually increase pressure to test specification

- Hold at test pressure for required duration (typically 30-60 seconds)

- Monitor for leakage, bulging, or other failure indicators

STEP 4: Result determination

- PASS: No leakage, no permanent deformation, no rupture

- FAIL: Any leakage, visible expansion, shell damage, or rupture

STEP 5: Post-test procedures

- Complete water drainage

- Thorough internal drying

- Reassembly (passing units only)

- Recharge with proper agent

- Test documentation and dating

Failed units require immediate destruction to prevent return to service. Passed units receive stamped test dates and return to service after proper recharge.

48Fire operates certified fire extinguisher testing facilities with proper equipment, safety protocols, and documentation systems meeting all regulatory requirements.

Internal Examination Procedure

Six-year internal examination for stored pressure extinguishers involves comprehensive assessment.

Disassembly and agent removal:

- Complete discharge through normal operating mechanism

- Valve assembly removal using appropriate tools

- Agent emptying and containment (some agents require special disposal)

- Component separation and identification

Internal inspection:

- Shell interior examination with lighting

- Corrosion assessment using inspection criteria

- Siphon tube verification (length, attachment, condition)

- Threads and collar inspection

- Any defects documented with photography

Component assessment:

- Valve body and seat inspection

- Spring and lever mechanism testing

- O-ring and seal examination

- Pressure gauge accuracy verification

- Hose and discharge assembly testing (where applicable)

Cleaning and preparation:

- Interior cleaning removing any contamination

- Component cleaning or replacement

- Thread cleaning and inspection

- Seal surface preparation

Reassembly and recharge:

- New seals and gaskets installation

- Proper torque application during reassembly

- Correct agent type and quantity

- Pressurization to specification

- Leak testing

- New tamper seal and service tag installation

The entire process typically requires 30-60 minutes per extinguisher depending on type and condition.

Functional Testing

Beyond hydrostatic and internal examination, functional testing verifies actual discharge performance.

Discharge testing:

- Complete discharge in controlled environment

- Verification of discharge time (should meet specifications)

- Assessment of agent distribution and throw distance

- Nozzle and hose performance verification

Not every extinguisher undergoes discharge testing—doing so would require recharge after every test. Instead, facilities typically:

- Test sample units from each equipment population

- Test any unit with suspected functional issues

- Discharge test units being retired from service

- Use test results to inform overall equipment reliability assessment

48Fire incorporates functional testing into fire extinguisher testing programs for facilities requiring maximum assurance of equipment performance.

—

SECTION 4: FAILURE MODES TESTING IDENTIFIES

Pressure Vessel Failures

The most critical failures involve pressure vessel integrity. These create safety hazards even before fires occur—extinguishers can rupture during normal handling if shells are compromised.

Corrosion-induced failure:

- Internal corrosion from moisture contamination

- External corrosion from environmental exposure

- Accelerated in coastal environments, chemical facilities, high-humidity areas

- Often invisible until hydrostatic testing reveals weakness

Stress fracture development:

- Microscopic cracks from impact damage

- Fatigue from repeated pressurization cycles

- Manufacturing defects becoming critical over time

- Undetectable without pressurized testing

Weld or seam failures:

- Original manufacturing defects

- Stress concentration at welds

- Material fatigue at seam points

- Progressive failure under normal pressure

Hydrostatic fire extinguisher testing identifies all these conditions before catastrophic failure occurs in the field.

Internal Component Degradation

Internal examination reveals problems invisible externally.

Siphon tube issues:

- Detachment from valve assembly (extinguisher won’t discharge agent)

- Corrosion creating holes (incomplete discharge)

- Misalignment preventing proper pickup (agent remains in shell)

- Physical damage from improper maintenance

Agent contamination:

- Moisture absorption in dry chemical agents (causes clumping)

- Chemical degradation over time

- Contamination from foreign materials

- Separation in foam or wet chemical agents

Valve mechanism problems:

- Spring fatigue (valve won’t operate properly)

- Corrosion preventing proper sealing

- Wear on operating lever or handle

- Seat degradation allowing pressure loss

These failures prevent proper extinguisher function even when pressure appears normal.

Pressure Loss Patterns

Testing programs reveal pressure loss patterns helping predict future failures.

Rapid pressure loss:

- Usually indicates valve or seal failure

- Can signal internal corrosion breakthrough

- Often follows impact damage

- Requires immediate replacement or repair

Gradual pressure loss:

- Normal seal degradation over time

- Environmental temperature cycling effects

- Minor valve wear

- Typically manageable through recharge

Intermittent pressure issues:

- Temperature-dependent seal problems

- Marginal valve seating

- Often precursor to complete failure

- Warrants closer monitoring or replacement

Systematic fire extinguisher testing documents these patterns, allowing predictive maintenance and replacement before equipment fails during emergencies.

—

SECTION 5: BUILDING TESTING PROGRAMS

Assessment and Planning

Effective fire extinguisher testing programs begin with comprehensive equipment assessment.

PHASE 1: Complete inventory

- Document all extinguisher locations, types, sizes

- Record manufacturing dates and last service dates

- Identify last hydrostatic test dates

- Note upcoming test deadlines

- Categorize by facility area and hazard type

PHASE 2: Test schedule development

- Calculate test windows based on NFPA intervals

- Group units for efficient batch testing

- Identify units past test deadlines requiring immediate service

- Plan temporary coverage for units removed for testing

- Coordinate testing with facility operational schedules

PHASE 3: Resource allocation

- Determine in-house vs. contracted testing

- Budget for testing costs and potential replacements

- Plan for temporary extinguisher needs during testing periods

- Establish documentation systems

- Train staff on testing program protocols

48Fire provides comprehensive fire extinguisher testing program development, creating customized schedules matching facility equipment populations and operational requirements.

Scheduling Strategies

Strategic scheduling minimizes operational disruption while maintaining compliance.

BATCH TESTING APPROACH:

- Group extinguishers by type and test interval

- Schedule concentrated testing periods

- Reduce per-unit testing costs through volume

- Simplify temporary coverage logistics

- Create predictable budget cycles

ROLLING SCHEDULE APPROACH:

- Distribute testing throughout the year

- Test portions of equipment population monthly or quarterly

- Smooth out costs and logistics

- Maintain steady workflow for testing providers

- Reduce temporary equipment needs

FACILITY-BASED APPROACH:

- Test all extinguishers in specific building areas together

- Coordinate with planned facility shutdowns or slow periods

- Minimize impact on any single department

- Simplify temporary coverage within zones

- Support area-specific compliance tracking

Each approach has advantages depending on facility size, equipment quantity, and operational patterns.

Temporary Coverage During Testing

Critical consideration: facilities must maintain fire protection while equipment undergoes testing.

TEMPORARY EXTINGUISHER DEPLOYMENT:

- 48Fire provides temporary units matching removed equipment specifications

- Temporary units meet all code requirements for type, rating, placement

- Clear marking distinguishes temporary from permanent equipment

- Documentation tracks temporary unit locations

- Return of tested equipment triggers temporary unit removal

COVERAGE PLANNING:

- Never remove all extinguishers from an area simultaneously

- Maintain minimum code-required coverage at all times

- Communicate temporary configurations to facility staff

- Post temporary location notifications where permanent units normally mount

- Verify adequate protection for specific hazards throughout testing period

Professional fire extinguisher testing services include temporary coverage coordination ensuring continuous compliance.

—

SECTION 6: DOCUMENTATION AND COMPLIANCE

Required Testing Records

NFPA 10 and OSHA require specific documentation for fire extinguisher testing.

HYDROSTATIC TEST RECORDS MUST INCLUDE:

- Extinguisher identification (serial number, location)

- Test date performed

- Test pressure applied

- Test duration

- Pass/fail result

- Technician name and certification

- Testing facility information

- Equipment calibration verification

RETENTION REQUIREMENTS:

- Records maintained until next test or extinguisher removal from service

- Minimum retention often exceeds test intervals

- Must be available for inspector review

- Electronic records acceptable if properly maintained

INTERNAL EXAMINATION DOCUMENTATION:

- Date of examination

- Components inspected

- Findings and condition assessment

- Parts replaced

- Agent type and quantity recharged

- Technician certification information

- Photographic documentation (recommended)

SERVICE TAG REQUIREMENTS:

- Physical tag attached to extinguisher

- Shows last service date

- Indicates next service due date

- Technician or company identification

- Must be durable and weather-resistant

48Fire maintains comprehensive digital fire extinguisher testing records with automatic retention, cloud backup, and instant access for compliance verification.

Compliance Verification

Fire marshals and OSHA inspectors verify testing compliance through multiple checkpoints.

PHYSICAL INSPECTION:

- Service tags showing test dates

- Visual verification of extinguisher condition

- Pressure gauge readings

- Proper mounting and accessibility

DOCUMENTATION REVIEW:

- Complete testing history

- Verification that tests occurred within required intervals

- Technician certification verification

- Testing facility accreditation confirmation

PATTERN ANALYSIS:

- Consistent testing schedules over time

- Appropriate response to failed tests

- Proper temporary coverage during testing periods

- Replacement decisions for aging equipment

Facilities with systematic fire extinguisher testing programs demonstrate compliance quickly through organized documentation and evident testing patterns.

Audit Preparation

Facilities can prepare for fire safety audits by maintaining testing program readiness.

DOCUMENTATION ORGANIZATION:

- Current inventory with all extinguisher details

- Testing schedules showing past and future test dates

- Complete historical records organized by location or equipment

- Technician and facility certifications current and accessible

- Temporary coverage logs for units currently in testing

PHYSICAL READINESS:

- All extinguishers with current service tags

- Clear markings on units approaching test deadlines

- Temporary units properly identified if present

- No obviously overdue equipment

- Proper mounting and accessibility throughout facility

STAFF PREPARATION:

- Key personnel familiar with testing program structure

- Contact information for testing provider readily available

- Understanding of testing schedules and requirements

- Ability to quickly retrieve documentation if requested

48Fire clients receive pre-audit support including documentation review, physical inspection, and immediate correction of any identified gaps.

—

SECTION 7: COST ANALYSIS

Testing Investment Breakdown

Understanding fire extinguisher testing costs helps facilities budget appropriately.

HYDROSTATIC TESTING COSTS:

- Typical range: $50-100 per extinguisher

- Includes removal, transport, testing, recharge, return

- Volume discounts often available for large facilities

- Specialized units (large wheeled, industrial) may cost more

- Failed units require replacement ($75-400 depending on type/size)

INTERNAL EXAMINATION COSTS:

- Typical range: $100-200 per extinguisher

- Includes disassembly, inspection, cleaning, reassembly, recharge

- Often combined with six-year maintenance requirements

- May identify components needing replacement (additional cost)

PROGRAM MANAGEMENT COSTS:

- Inventory tracking systems

- Documentation management

- Schedule coordination

- Temporary equipment

- Staff training

ANNUAL PROGRAM COST ESTIMATE:

For 100-extinguisher facility with mixed types and ages:

- Annual: $3,000-6,000 for routine maintenance and inspections

- Testing year (20% of equipment due): Additional $2,000-4,000

- Heavy testing year (50% of equipment due): Additional $5,000-10,000

Costs distribute over time based on testing schedules. Properly planned programs avoid budget spikes.

Failure Cost Comparison

Testing costs compare favorably against failure consequences.

EQUIPMENT FAILURE DURING FIRE:

- Property damage from fire spread: Highly variable, potentially hundreds of thousands

- Business interruption: $5,000-50,000+ per day depending on operation

- Injury liability: Potentially millions in severe cases

- Insurance claim impacts: Premium increases, coverage limitations

- Reputation damage: Unmeasurable but significant

COMPLIANCE FAILURE COSTS:

- OSHA serious violation: $15,625 per citation

- Fire marshal citations: Variable by jurisdiction, $500-5,000 typical

- Reinspection fees: $200-500 per visit

- Emergency testing/replacement: Premium rates, 50-100% higher than planned service

- Operational disruption during emergency corrections

RISK ASSESSMENT:

- Single equipment failure during actual fire: Potentially catastrophic

- Single compliance violation: $15,000+ certain cost

- Annual testing program: $2,000-10,000 predictable investment

The cost-benefit analysis overwhelmingly favors systematic fire extinguisher testing over reactive approaches or testing avoidance.

ROI Calculation

Return on investment for fire extinguisher testing programs comes from multiple sources.

DIRECT SAVINGS:

- Early identification of failing equipment before emergency replacement needs

- Avoidance of compliance violations and associated penalties

- Prevention of insurance complications from inadequate maintenance

- Extended equipment life through proper maintenance

- Reduced emergency service costs through planned testing

RISK MITIGATION VALUE:

- Equipment reliability during actual fires

- Reduced liability exposure from equipment failures

- Maintained business continuity

- Protected reputation and stakeholder confidence

EFFICIENCY GAINS:

- Predictable budgeting vs. emergency response costs

- Organized documentation reducing audit preparation time

- Systematic approach reducing management overhead

- Professional service allowing staff focus on core responsibilities

Most facilities achieve positive ROI within first testing cycle through violation avoidance alone.

—

SECTION 8: TECHNOLOGY IN TESTING PROGRAMS

Digital Tracking Systems

Modern fire extinguisher testing programs leverage technology for improved compliance and efficiency.

INVENTORY MANAGEMENT:

- Digital equipment databases with complete specifications

- Location tracking with facility mapping

- Automatic test deadline calculations

- Alert systems for approaching deadlines

- Historical service record integration

MOBILE INSPECTION TOOLS:

- Tablet or smartphone applications for field use

- Barcode or QR code equipment identification

- Photographic documentation integration

- GPS verification of inspection locations

- Real-time data synchronization

CLOUD-BASED DOCUMENTATION:

- Permanent record storage with automatic backup

- Instant access from anywhere for audit support

- Multi-facility management from single platform

- Customizable reporting for different stakeholders

- Integration with facility management systems

48Fire provides clients with advanced digital fire extinguisher testing platforms offering real-time visibility into compliance status across entire equipment populations.

Automated Compliance Management

Technology enables proactive compliance rather than reactive scrambling.

AUTOMATED SCHEDULING:

- System calculates test due dates based on NFPA intervals

- Automatic service appointment proposals

- Calendar integration for facility coordination

- Reminder notifications to multiple stakeholders

- Rescheduling coordination for operational conflicts

EXCEPTION REPORTING:

- Automatic identification of overdue tests

- Failed equipment tracking requiring replacement decisions

- Units approaching test intervals flagged for planning

- Missing documentation alerts

- Temporary coverage status monitoring

ANALYTICS AND TRENDS:

- Failure rate analysis by equipment type, age, location

- Testing cost trending and budget forecasting

- Compliance percentage tracking over time

- Equipment replacement timing optimization

- Service provider performance metrics

These capabilities transform fire extinguisher testing from administrative burden to managed process requiring minimal facility staff involvement.

Predictive Maintenance Applications

Advanced programs use testing data to predict future needs.

FAILURE PATTERN RECOGNITION:

- Equipment types showing higher failure rates

- Age thresholds where failures increase significantly

- Environmental factors correlating with premature failure

- Manufacturer or model-specific reliability patterns

REPLACEMENT PLANNING:

- Identification of equipment approaching end-of-life

- Budget forecasting for future replacement needs

- Strategic timing of replacements vs. continued testing

- Equipment standardization opportunities

TESTING OPTIMIZATION:

- Risk-based testing frequency adjustments

- Cost-effective test interval analysis

- Batch testing optimization for efficiency

- Resource allocation improvements

Data-driven approaches improve both compliance and cost-effectiveness of fire extinguisher testing programs.

—

SECTION 9: COMMON TESTING MISTAKES

Deferring Tests Beyond Deadlines

The most common fire extinguisher testing failure is simply not testing equipment when required.

WHY IT HAPPENS:

- Lack of awareness of testing requirements

- Budget constraints leading to postponement

- Assumption that visual inspection suffices

- Administrative oversight—no system tracking deadlines

- Perceived low priority vs. other facility needs

THE CONSEQUENCES:

- OSHA violations when discovered ($15,625+ per serious citation)

- Fire marshal citations and potential operating restrictions

- Equipment failures during actual fires

- Liability exposure if failures contribute to injuries or damage

- Insurance complications during claims or underwriting

THE SOLUTION:

Professional fire extinguisher testing services with automated deadline tracking ensure tests occur within required intervals without facility staff having to remember schedules.

48Fire provides complete schedule management, proactively coordinating testing before deadlines while accommodating facility operational requirements.

Using Uncertified Testing Providers

Some facilities attempt to reduce costs by using uncertified technicians or inadequate testing equipment.

PROBLEMS WITH UNCERTIFIED TESTING:

- Test results may not meet NFPA standards

- Equipment may lack proper calibration

- Technicians may not understand proper procedures

- Documentation may not satisfy inspector requirements

- Liability issues if improperly tested equipment fails

Fire marshals and OSHA inspectors verify testing provider certifications. Tests performed by unqualified providers don’t satisfy compliance requirements.

Inadequate Documentation

Performing tests but failing to maintain proper records creates compliance problems equivalent to not testing.

DOCUMENTATION FAILURES:

- Missing test dates or technician information

- Lost records from previous testing cycles

- Incomplete test result documentation

- No calibration records for testing equipment

- Illegible or damaged service tags

Inspectors encountering documentation gaps issue violations even when equipment was actually tested.

Ignoring Failed Test Results

Facilities sometimes continue using extinguishers that failed hydrostatic testing or internal examination.

THIS VIOLATES NFPA 10 EXPLICITLY:

- Failed units must be removed from service immediately

- Pressure vessels failing hydrostatic tests must be destroyed

- Units with severe internal corrosion require replacement

- No repairs can make failed pressure vessels acceptable

Continuing to use failed equipment creates enormous liability and represents willful violation of safety standards.

Poor Temporary Coverage

Removing large numbers of extinguishers for testing without adequate temporary replacements.

COMPLIANCE ISSUES:

- Facilities must maintain minimum code-required fire protection at all times

- Gaps in coverage violate fire codes even during testing periods

- Create liability exposure if fires occur during gaps

- Fire marshals discovering inadequate coverage during routine inspections issue citations

Professional fire extinguisher testing programs include comprehensive temporary coverage ensuring continuous compliance.

—

SECTION 10: IMPLEMENTING YOUR TESTING PROGRAM

Getting Started

Facilities without systematic fire extinguisher testing programs can implement them through structured approach.

STEP 1: Current state assessment

Contact 48Fire for comprehensive facility assessment including:

- Complete equipment inventory with locations, types, ages

- Review of existing testing records

- Identification of overdue tests requiring immediate action

- Evaluation of equipment condition

- Compliance gap analysis

STEP 2: Immediate correction

Address any equipment currently overdue for testing:

- Units past hydrostatic test intervals go for immediate testing

- Equipment past six-year examination receives internal inspection

- Obviously deficient units get replaced

- Documentation gets organized and updated

- Temporary coverage installs where needed during correction period

STEP 3: Program design

Develop comprehensive fire extinguisher testing program:

- Establish testing schedules based on NFPA intervals

- Define testing provider relationship (contracted services recommended)

- Implement tracking systems for ongoing management

- Create budget allocations for testing and potential replacements

- Establish staff training on program protocols

STEP 4: Ongoing execution

Launch systematic program operation:

- Professional testing occurs per established schedules

- Documentation maintains automatically through provider systems

- Facility staff receives notifications of upcoming service

- Failed equipment decisions make promptly

- Annual program reviews ensure continued effectiveness

Selecting Testing Providers

Choosing qualified fire extinguisher testing providers ensures program success.

ESSENTIAL QUALIFICATIONS:

- Certified technicians with appropriate training

- Accredited testing facilities with calibrated equipment

- Comprehensive insurance coverage

- Demonstrated NFPA 10 compliance expertise

- Strong documentation systems

- Ability to provide temporary coverage during testing

EVALUATION CRITERIA:

- References from similar facilities

- Response time for testing services

- Transparent pricing structure

- Geographic service coverage

- Digital platform capabilities

- Customer service accessibility

48Fire meets all certification requirements, maintains state-of-the-art testing facilities, provides comprehensive temporary coverage, and offers advanced digital tracking accessible to clients 24/7.

Staff Training Requirements

Facility staff need training on fire extinguisher testing program protocols even when using professional services.

TRAINING CONTENT:

- Understanding testing requirements and schedules

- Recognizing equipment approaching test deadlines

- Proper procedures when equipment goes for testing

- Temporary extinguisher protocols

- Documentation access and inspector support

- Reporting damaged or questionable equipment

48Fire provides complimentary facility staff training as part of fire extinguisher testing program implementation.

—

SECTION 11: BEYOND TESTING—COMPLETE FIRE PROTECTION

Fire extinguisher testing represents one component of comprehensive fire safety programs.

Integrated Fire Safety Systems

Facilities implementing systematic fire extinguisher testing often expand to complete fire protection management.

ADDITIONAL SERVICES:

- Fire alarm system testing and maintenance

- Fire sprinkler system inspection and testing

- Emergency lighting verification

- Fire door and fire damper testing

- Special hazard system maintenance

- Fire pump testing

48Fire provides integrated fire protection services coordinating all testing and maintenance through unified platform ensuring nothing gets overlooked.

Compliance Dashboard Benefits

Comprehensive programs provide single-source visibility across all fire safety equipment.

UNIFIED TRACKING:

- All fire protection equipment in one database

- Coordinated testing schedules across systems

- Consolidated compliance reporting

- Single point of contact for all services

- Simplified audit preparation

Facilities managing fire extinguisher testing, alarm testing, sprinkler inspection, and other requirements through multiple vendors face coordination challenges and documentation gaps. Integrated approaches eliminate these problems.

Long-Term Partnership Value

Fire safety compliance is ongoing—not project-based. Long-term relationships with qualified providers deliver increasing value over time.

RELATIONSHIP BENEFITS:

- Provider develops deep facility knowledge

- Historical data supports better decision-making

- Trust enables efficient coordination

- Consistent service quality

- Predictable costs and schedules

- Reduced administrative burden on facility staff

48Fire focuses on long-term client relationships, investing in facility understanding and customized service approaches that improve efficiency and effectiveness over years of partnership.

—

CONCLUSION: TESTING TRANSFORMS COMPLIANCE

Fire extinguisher testing separates genuine fire protection from compliance theater. Visual inspection and basic maintenance cannot verify equipment will actually function during fires. Only systematic testing provides that assurance.

The 80% failure reduction isn’t theoretical—it’s measurable outcome from replacing assumption with verification. Equipment that receives proper testing either works reliably or gets identified for replacement before failures occur in the field.

Costs are modest. Benefits are substantial. Implementation is straightforward when using qualified providers.

Facilities serious about fire safety implement systematic fire extinguisher testing programs. Those treating extinguishers as decorative wall fixtures discover their mistake during fires or inspections—when correction becomes expensive and consequences become severe.

—

TAKE ACTION

48Fire provides complete fire extinguisher testing services including:

- Hydrostatic testing with certified facilities

- Six-year internal examination programs

- Automated schedule management and deadline tracking

- Complete temporary coverage during testing

- Digital documentation with instant audit access

- Coordinated service minimizing operational disruption

Talk to an Expert! Contact 48Fire at [/contact-us](/contact-us) to schedule a facility assessment. Our certified technicians will evaluate your current fire extinguisher testing program, identify compliance gaps, and implement systematic testing that transforms equipment reliability while maintaining full regulatory compliance.

—

FREQUENTLY ASKED QUESTIONS

What is hydrostatic testing for fire extinguishers?

Hydrostatic testing verifies pressure vessel integrity by pressurizing the empty extinguisher with water to levels exceeding normal operating pressure. Units passing the test demonstrate they can safely contain discharge pressures. Units failing show weaknesses requiring replacement. NFPA 10 requires hydrostatic testing at specific intervals: every 5 years for CO2, water, and foam extinguishers; every 12 years for dry chemical stored pressure units.

How much does fire extinguisher testing cost?

Hydrostatic testing typically costs $50-100 per extinguisher including removal, transport, testing, recharge, and return. Internal examination costs $100-200 per unit. Actual costs vary based on extinguisher type, size, facility location, and service volume. Failed units require replacement adding $75-400 depending on specifications. 48Fire provides transparent pricing and volume discounts for facilities with large equipment populations.

Can facilities perform their own hydrostatic testing?

No. NFPA 10 requires hydrostatic testing be performed by trained persons with suitable testing equipment and facilities. This means certified technicians with calibrated pressure testing equipment, proper safety enclosures, and documentation systems. DIY testing violates standards and creates liability. Fire marshals reject uncertified testing during inspections.

What happens if a fire extinguisher fails hydrostatic testing?

Units failing hydrostatic testing must be permanently removed from service and destroyed to prevent return to use. The pressure vessel has demonstrated inability to safely contain operating pressures. Failed units cannot be repaired—they require complete replacement. 48Fire provides immediate replacement recommendations and options when testing identifies failed equipment.

How often do fire extinguishers need testing?

Testing frequency depends on extinguisher type per NFPA 10. CO2, water, and foam extinguishers require hydrostatic testing every 5 years. Dry chemical stored pressure extinguishers test every 12 years. All stored pressure extinguishers undergo internal examination every 6 years. Monthly visual inspections and annual maintenance continue regardless of testing schedules.

Do all extinguishers in a facility test simultaneously?

No. Strategic fire extinguisher testing programs schedule tests based on equipment age and type, distributing testing throughout multi-year cycles. This spreads costs, minimizes temporary coverage needs, and reduces operational disruption. 48Fire develops customized testing schedules matching facility operational requirements and budget preferences.

What documentation do inspectors require for fire extinguisher testing?

Inspectors verify testing occurred within required intervals through service tags on each extinguisher and detailed testing records. Documentation must include test dates, test pressures, pass/fail results, technician certification, and testing facility information. Records must be retained until next test or equipment removal from service. 48Fire provides complete digital and physical documentation meeting all inspection requirements.

Can facilities continue operating while extinguishers are being tested?

Yes, when proper temporary coverage is provided. 48Fire supplies temporary extinguishers matching removed equipment specifications, maintaining code-required fire protection throughout testing periods. Facilities never operate without required equipment. Temporary units install immediately when permanent equipment is removed for testing.