Fire Extinguisher Maintenance Costs Explained

Opening hook: The invisible cost of safety is easy to overlook until you’re staring at a renewal invoice, a service disruption, or a failed inspection notice. For facilities managers, the true cost of keeping portable and semi-portable extinguishers in code—and ready to perform when every second counts—stretches beyond the sticker price of a service call. It includes regulatory compliance, downtime, travel, equipment replacement, and the assurance that every extinguisher will perform as expected during a crisis. This article dives into fire extinguisher maintenance cost, the drivers behind those costs, and practical steps to optimize your annual fire extinguisher service without compromising safety or compliance.

Table of Contents

- Why extinguisher maintenance costs matter

- What is included in annual fire extinguisher service?

- Regulatory backbone and its impact on cost

- Cost drivers: the components that drive the price tag

- Cost ranges and planning for facilities of different sizes

- Strategies to manage and reduce maintenance costs

- Choosing the right maintenance partner

- Real-world scenarios: budgeting for upkeep in different environments

- 48Fire Protection: our approach to extinguisher maintenance

- Key takeaways and quick-reference checklist

- Citations

Why extinguisher maintenance costs matter

An extinguisher is a critical safety device, but maintaining it is a long-term operational expense. The price you pay for upkeep isn’t just the service fee; it’s a package that covers preventive maintenance, compliance with standards, and the reliability of lifesaving equipment when it’s needed most. For facilities with dozens or hundreds of extinguishers, small per-unit costs can accumulate into a substantial annual budget. The right maintenance strategy balances budget with safety, ensuring you meet legal requirements while avoiding avoidable failures.

- Real-world consequence: missed inspections or expired hydrostatic tests can lead to fines, mandated downtime, or replacement costs far in excess of routine maintenance.

- The compliance tether: multiple regulatory bodies set the cadence for inspections, restocks, and testing, which translates directly into service pricing and scheduling.

What is included in annual fire extinguisher service?

Annual fire extinguisher service is more comprehensive than a simple, quick check. The typical lifecycle for portable extinguishers includes several layers of maintenance and verification, each with its own cost implications.

Core components of annual extinguisher service

- Monthly visual inspections: Quick checks performed by on-site staff or service technicians to confirm accessibility, legibility of pressure gauges, no obvious physical damage, and proper tagging. This is mandated by the standard for portable extinguishers and forms the first line of safety assurance. [OSHA 1910.157 – Portable Fire Extinguishers](https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157)

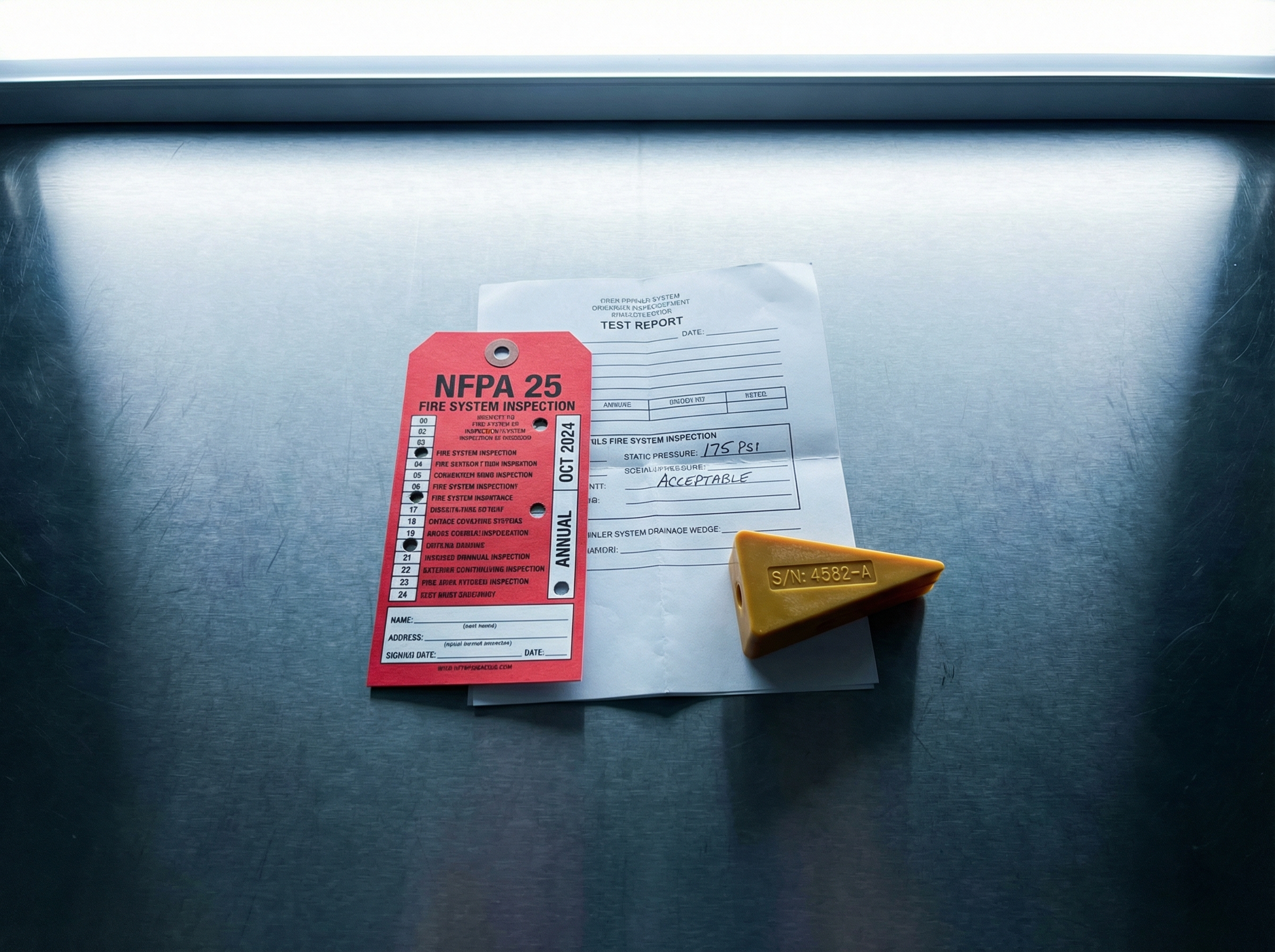

- Annual maintenance/maintenance service: A more thorough service by a qualified technician, including functional checks, weighing (where applicable), cleaning, and ensuring the device remains within its listed operating range and meets NFPA 10 requirements.

- Hydrostatic testing: A pressure-resistance test to verify the integrity of the extinguisher cylinder. The interval depends on the extinguisher type and manufacturer’s instructions, typically every 5–12 years. The 2024 rulemaking update provides a regulatory context for hydrostatic testing requirements and related cost burdens [OSHA Hydrostatic Testing Provision, 2024 Rulemaking](https://www.osha.gov/laws-regs/federalregister/2024-01-09-0).

- Recharge and re-qualification: If a unit has discharged, or if through testing a component needs replacement, the extinguisher must be recharged or re-qualified to meet the original performance specification.

- Certification and documentation: Service reports, calibration records, and compliance certificates for regulatory bodies and property records.

- Travel and logistics: Travel time, on-site access, and any building-specific coordination that may affect pricing.

Key note on scope

- For fixed or “semi-portable” extinguishing systems (such as clean agent, foam, or water-based systems integrating with building infrastructure), the maintenance scope can be more complex and costly than standard portable units. The same principles apply but the cadence and testing methods can differ. In many cases, the Coast Guard and other regulatory bodies have specific criteria for servicing, including consistent documentation and qualified servicing agencies. [Cornell Law – Coast Guard regulations, 46 CFR 107.235](https://www.law.cornell.edu/cfr/text/46/107.235)

—

Horizontal rule

Regulatory backbone and its impact on cost

Cost discussions around extinguisher maintenance are not just about the price tag; they’re also a story about compliance. Several regulatory frameworks shape the maintenance cadence, the rigorousness of testing, and the certification requirements that a service provider must meet. These rules influence both the frequency of service and the complexity of the work performed, which in turn affects overall costs.

- OSHA standard 1910.157 sets the foundation for portable extinguishers, including monthly visual inspections and annual maintenance, with hydrostatic testing intervals depending on the extinguisher type. This standard directly informs the schedule most facilities adhere to and thus the pricing models service providers use for planning resources. [OSHA 1910.157 – Portable Fire Extinguishers](https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157)

- The 2024 OSHA rulemaking on hydrostatic testing provisions quantifies the regulatory burden in terms of hours and operation/maintenance costs, underscoring why hydrostatic testing is a major line item in annual budgets. While these figures frame national cost implications, local costs will vary by market and service provider. [Hydrostatic Testing Provision of the Standard on Portable Fire Extinguishers – 2024 Rulemaking](https://www.osha.gov/laws-regs/federalregister/2024-01-09-0)

- Coast Guard regulations for servicing portable and installed fire extinguishing systems require NFPA 10-compliant servicing, including monthly inspections and annual maintenance, with certification for servicing agencies. This adds an additional layer of compliance with corresponding service costs for facilities operating under maritime or mixed-use environments. [Coast Guard regulations – 46 CFR 107.235](https://www.law.cornell.edu/cfr/text/46/107.235)

- NFPA 10 (Standard for Portable Fire Extinguishers) underpins best practices for servicing, maintenance, and testing, providing industry-accepted criteria for performance and reliability. Service pricing often aligns with what NFPA 10 requires as the baseline for proper extinguisher care. For a current overview of this standard, see the NFPA standards catalog. [NFPA 10 – Portable Fire Extinguishers](https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=10)

—

Horizontal rule

Cost drivers: the components that drive the price tag

Understanding the factors that push maintenance costs upward—or downward—helps facilities plan more accurately. The following are the primary cost drivers in most markets today.

1) Type and size of extinguishers

- Smaller, standard ABC or BC dry chemical extinguishers (2.5–5 lb) tend to have lower service costs than larger ABC, CO2, or special-agent extinguishers.

- Specialty extinguishers (e.g., clean agent systems, high-hose-equipped units) require more specialized testing, recharging, and documentation, raising per-unit costs.

2) Quantity and configuration

- More extinguishers mean higher cumulative costs, but some economies of scale apply as technicians can service multiple units per site visit. Large facilities often negotiate bundled pricing for annual service contracts.

3) Accessibility and location

- Extinguishers in hard-to-reach areas, remote buildings, or after-hours access can incur travel surcharges or scheduling premiums.

4) Equipment condition and history

- Extinguishers with expired hydrostatic testing or those showing signs of damage can require additional services, factoring into the overall cost.

5) Certification and documentation

- Some industries and jurisdictions demand rigorous, auditable records; the cost to generate, store, and maintain these records is a fixed portion of the overall service price.

6) Service type mix

- A facility that requires both routine monthly inspections and annual maintenance plus hydrostatic testing will incur more frequent service charges and potential service-call fees than a facility that only requires a baseline annual visit.

7) Regulatory compliance and reporting

- Some service providers include compliance reporting as part of the package, while others bill separately for required documentation packages. The presence or absence of robust digital reporting platforms can influence price transparency and total cost of ownership.

8) Market dynamics

- Local labor rates, competition among certified providers, and regional demand for safety services can create price differentials. Regions with higher labor costs or fewer qualified technicians can see higher per-unit maintenance prices.

The combined effect of these drivers determines the “annual fire extinguisher service” price you’ll see on invoices. To illustrate, a typical cost breakdown might break out into a per-unit charge for regular maintenance, plus a per-unit hydrostatic testing surcharge when due, plus any travel or emergency call fees.

—

Horizontal rule

Cost ranges and planning for facilities of different sizes

Prices vary by market, but the industry does show common patterns. The following ranges are illustrative and intended to help facilities budget. Actual pricing will depend on your location, extinguisher types, distribution, and the chosen service provider. Where possible, partner with a service that offers bundled pricing for annual service, hydrostatic testing, and recharging to simplify budgeting and reduce surprises.

- Monthly visual inspection by on-site staff (or included as part of a contracted service): often included in an annual service plan or offered as a low per-unit monthly check-in; if billed separately, a typical per-unit price might be modest, reflecting the simplicity of the task, e.g., a few dollars per unit per month.

- Annual maintenance (portable units): per unit annual service typically ranges from $8 to $25 per unit in many markets, depending on unit type, accessibility, and whether certification documentation is included.

- Hydrostatic testing (intervals vary by extinguisher type; testing costs per unit often range from $25 to $70, plus replacement parts if needed, with some markets charging more for specialized units).

- Recharge costs: if an extinguisher has discharged or failed the hydrostatic test, recharging and re-qualification may range from $15 to $40 per unit, depending on the agent and the cylinder size.

- Certification and documentation: if included in a service contract, pricing is rolled into the per-unit and annual costs; if charged separately, expect an administrative fee in the range of a few dollars per unit per year or per service event.

- Travel charges and service-call fees: Depending on the provider and travel distance, a service call may incur a base fee plus a per-unit charge or a fixed one-time travel charge.

Cost table: typical per-unit costs at a glance

| Service Type | Frequency | Typical Cost per Unit | Notes |

|---|---|---|---|

| Monthly visual inspection (on-site by staff or remote check) | Monthly | Often included in contract; $0–$5 if billed separately | Quick, non-invasive; ensures accessibility and legibility of labels |

| Annual maintenance | Annually | $8–$25 | Includes functional checks, cleaning, and labeling; may include documentation |

| Hydrostatic testing | Every 5–12 years (depends on extinguisher) | $25–$70 | Cylinder integrity test; higher for specialty agents |

| Recharge after discharge | As needed | $15–$40 | Agent cost plus service time; larger extinguishers cost more |

| Certification/documentation | Annually | $1–$5 per unit or bundled | Administrative costs for compliance records |

| Travel/onsite service call | Per visit | $50–$150 base plus per-unit | Regional variation impacts the total cost |

Note: The above table reflects common industry patterns and is intended for budgeting purposes. The actual pricing will depend on the extinguisher mix, site complexity, and the service provider’s pricing model.

—

Horizontal rule

Strategies to manage and reduce maintenance costs

Smart budgeting for fire extinguisher maintenance requires a mix of proactive planning, vendor management, and operational discipline. The following strategies can help you optimize costs without sacrificing safety or compliance.

1) Consolidate maintenance into a single provider or a bundled service contract

- Bundle annual maintenance, hydrostatic testing, recharge, and documentation into one contract to secure predictable pricing and minimize on-site fees.

- A single provider improves scheduling consistency, reduces administrative overhead, and simplifies compliance reporting.

2) Plan with a long-term testing schedule in mind

- Work with your service partner to align hydrostatic testing windows with facility downtime or low-occupancy periods to minimize business disruption and travel costs.

- Early planning for out-of-cycle tests can help negotiate favorable pricing.

3) Optimize extinguisher placement and accessibility

- Consolidate units in shared compartments where possible; ensure signage and visibility reduce unnecessary site visits or returns due to labeling issues.

- Ensure clear access to all extinguishers to avoid rework caused by awkward placement during service visits.

4) Leverage digital documentation and compliance automation

- Choose providers offering digital inspection reports, asset tags, and centralized dashboards that reduce administrative time and errors.

- Digital records expedite annual reporting, reduce paper-based costs, and simplify regulatory audits.

5) Establish an annual audit and inventory process

- Regularly verify extinguisher counts and types; identify units due for hydrostatic testing well in advance.

- Maintain an up-to-date inventory to avoid last-minute emergencies that trigger premium service calls.

6) Consider performance-based or value-based pricing for complex systems

- For facilities with unusual configurations or complex installed systems, negotiate pricing tied to performance outcomes and predictable service delivery timelines.

7) Invest in operator training for monthly visual inspections

- Train facility staff to perform proper monthly checks (gauge readings, tamper seals, accessibility) to catch obvious issues and reduce emergency service calls between routine visits.

8) Use a standardized extinguisher mix where feasible

- A uniform extinguisher type across facilities can streamline maintenance, stocking, and training, lowering per-unit costs by reducing the range of spare parts and agents needed.

Pro tip: When negotiating contracts, ask suppliers for a “not-to-exceed” price for the entire year, plus a 2–3% annual inflation cushion. This helps align expectations and keeps budgets in check even as market costs rise.

—

Horizontal rule

How to choose the right maintenance partner

Selecting the right extinguisher maintenance partner is as important as selecting the right extinguishers. A good partner is not just a vendor; they’re a reliability partner who helps you stay compliant and safe. Consider these filters when evaluating quotes and capabilities.

- Certifications and credentials

- Ensure technicians are certified to service portable extinguishers and are familiar with NFPA 10. Check for reputable certifications from recognized authorities and manufacturer approvals.

- Regulatory alignment

- Confirm that the provider is familiar with OSHA requirements (1910.157), Coast Guard regulations (where applicable), and the relevant federal and state guidelines for your facility type.

- Documentation practices

- Look for providers that deliver detailed service reports, serial-number-level documentation, and an auditable record that makes regulatory audits straightforward.

- Service model and scheduling

- Ask about contracted service frequency, response times for urgent service, and how they manage hydrostatic testing windows.

- Pricing transparency

- Favor providers with clear, itemized price quotes that separate routine maintenance, hydrostatic testing, and travel fees. Beware bundled prices that obscure essential line items.

- Customer references and case studies

- Request references to understand how the provider performs in environments similar to yours (e.g., healthcare, education, manufacturing, or hospitality).

- Service-level guarantees

- Seek explicit commitments on response times, on-site availability, and quality of documentation.

- Environmental and industry considerations

- If your facility has chemical, clean agent, or environmental concerns, verify the provider has experience with your particular system and its agent sustainability and disposal requirements.

Q&A style quick guide

- Q: How often should hydrostatic testing occur?

- A: Intervals depend on extinguisher type and manufacturer, typically every 5–12 years. The regulatory landscape and the 2024 OSHA rulemaking update are important context for this cadence. [OSHA Hydrostatic Testing Provision, 2024 Rulemaking](https://www.osha.gov/laws-regs/federalregister/2024-01-09-0)

- Q: Do monthly visual inspections count toward annual maintenance?

- A: Yes. OSHA requires monthly visual inspections in many circumstances, and these checks are a fundamental part of ongoing compliance. [OSHA 1910.157 – Portable Fire Extinguishers](https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157)

- Q: What about maritime or Coast Guard considerations?

- A: Coast Guard regulations require NFPA 10-compliant servicing and proper certification for servicing agencies; this can affect pricing for marine facilities or those with maritime components. [Coast Guard regulations – 46 CFR 107.235](https://www.law.cornell.edu/cfr/text/46/107.235)

—

Horizontal rule

Real-world scenarios: budgeting for upkeep in different environments

To give a practical sense of what maintenance costs look like in different environments, consider two representative scenarios. These hypothetical cases illustrate how the same service categories translate into real-world budgets.

Scenario A: A mid-sized office building (~200 extinguishers)

- Profile: Mixed-use building with corridors, open office spaces, and multiple mechanical rooms.

- Maintenance mix: Annual maintenance for all portable units, with hydrostatic testing scheduled for units due in the current cycle.

- Estimated annual cost range (per unit basis, with discount for bundled service): $12–$28 for annual maintenance, plus $25–$60 per hydrostatic test for units due in this cycle, plus minor travel fees.

- Total annual maintenance cost (example): If 200 units fall into typical categories, annual maintenance could fall in the range of $2,400–$5,600, plus hydrostatic testing as required (depending on the specific age and type mix).

Scenario B: A healthcare facility with specialized extinguishers

- Profile: A hospital or clinical facility with a mix of standard portable extinguishers and a few specialty units (e.g., clean agents) requiring more rigorous testing and documentation.

- Maintenance mix: Monthly inspection program, annual maintenance with documentation, and hydrostatic testing for specific units on the recommended schedule.

- Estimated annual cost range (per unit basis): Higher per-unit maintenance due to documentation and specialized equipment, roughly $15–$40 per unit for annual maintenance; hydrostatic testing for relevant units at $40–$70 per unit on the cycle.

- Total annual maintenance cost (example): 300 units with a 25% requiring hydrostatic testing in a given year could see maintenance costs around $4,500–$9,000 plus testing costs.

Case study summaries

- Case Study 1: A university campus transitioned from a patchwork of service providers to a bundled annual service contract. Result: improved scheduling predictability, per-unit pricing reductions, and more robust compliance reporting. The campus reported a reduction in emergency service calls due to better maintenance hygiene and proactive testing.

- Case Study 2: A manufacturing facility with larger extinguishers and special agents achieved better cycle management by aligning hydrostatic testing windows with planned shut-down periods, reducing travel costs and minimizing production downtime.

Key takeaways

- A bundled approach to annual fire extinguisher service, including maintenance, testing, recharging, and documentation, typically yields lower total costs and easier budgeting than ad hoc individual services.

- Hydrostatic testing is a significant cost driver due to the specialized equipment and regulatory considerations; plan these tests well in advance and coordinate with downtime to avoid lost production.

- Proper planning, a consistent service cadence, and a trusted provider can produce measurable cost savings while maintaining safety and compliance.

—

Horizontal rule

48Fire Protection: our approach to extinguisher maintenance (near the end)

At 48Fire Protection, we view extinguisher maintenance as a safety program—not a series of checkboxes. Our approach combines regulatory expertise, field-proven processes, and transparent pricing designed to minimize downtime and maximize reliability.

What sets us apart

- Regulatory alignment: We stay current with OSHA 1910.157 requirements and the latest hydrostatic testing provisions, ensuring your program stays compliant with minimal risk of penalties or recalls. See regulatory references for context: OSHA 1910.157 and the hydrostatic testing provisions. [OSHA 1910.157 – Portable Fire Extinguishers](https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157) [Hydrostatic Testing Provision of the Standard on Portable Fire Extinguishers – 2024 Rulemaking](https://www.osha.gov/laws-regs/federalregister/2024-01-09-0)

- Coast Guard and NFPA compatibility: For facilities under maritime or specialized usage, we maintain NFPA 10-aligned servicing, with proper certification and documentation readiness. [Coast Guard regulations – 46 CFR 107.235](https://www.law.cornell.edu/cfr/text/46/107.235) [NFPA 10 – Portable Fire Extinguishers](https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=10)

- Transparent pricing and service models: We offer bundled annual service programs that include monthly inspections, annual maintenance, hydrostatic testing, recharge services, and digital documentation. We price transparently to avoid surprises in the budget, with clear per-unit and per-visit charges.

- Comprehensive service portfolio: Portable extinguishers, semi-portable extinguishing equipment, and fixed fire suppression systems are supported by a unified service team to ensure consistent quality and continuity of service.

Our services for extinguisher maintenance

- On-site monthly visual inspections with prompt reporting

- Comprehensive annual maintenance including functional checks, cleaning, labeling, and re-certification support

- Hydrostatic testing coordination and execution with compliant documentation

- Recharge and re-qualification services after discharge or testing

- Real-time digital asset management, including mobile access to service reports and compliance certificates

- Replacement planning and parts stocking for common extinguisher models

- Safe disposal and recycling of expired or decommissioned cylinders in accordance with environmental guidelines

What you’ll experience with us

- Predictable budgeting: Clear pricing with a bundled annual program that covers all essential maintenance elements

- Reduced downtime: Scheduling that minimizes disruption during business hours and production cycles

- Compliance confidence: Documentation that stands up to audits and regulatory reviews

- Proactive risk management: Early detection of issues through routine checks and professional testing

Service packages we offer

- Essential Auto-Inspect: Monthly inspections plus annual maintenance and digital reporting

- Pro-Active Shield: Essential maintenance plus hydrostatic testing, priority scheduling, and enhanced documentation

- Full-Spectrum Compliance: Comprehensive coverage with end-to-end compliance reporting, regulatory liaison support, and fleet management for large facilities

Callout: Why 48Fire Protection for extinguisher maintenance

- Our technicians are NFPA 10 trained and Coast Guard-certified where required

- We tailor service plans to your facility type, occupancy, and risk profile

- We provide transparent, itemized quotes with no hidden costs

- We track and manage your extinguisher inventory, ensuring timely testing and replacement so you stay in compliance and minimize downtime

End-of-section note

If you’d like to explore a tailored extinguisher maintenance plan for your facility, our team can provide a no-obligation assessment and a transparent cost proposal.

—

Horizontal rule

Key takeaways and quick-reference checklist

- Fire extinguisher maintenance costs are driven by unit type, number of units, accessibility, and regulatory requirements. Understanding the full scope—from monthly inspections to hydrostatic testing—helps you budget accurately. [OSHA 1910.157](https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157) and [2024 OSHA hydrostatic testing provisions](https://www.osha.gov/laws-regs/federalregister/2024-01-09-0) provide the regulatory context.

- Hydrostatic testing is a major cost driver; plan cycles around downtime windows to minimize disruption.

- Bundled service contracts with a single provider often yield better pricing and simplified compliance reporting than piecemeal arrangements.

- Documentation and certification are not optional add-ons; they’re integral to compliance and future audits.

Checklist: Are you set for annual fire extinguisher service?

- [ ] All extinguishers have up-to-date serial numbers and locations logged in your asset management system.

- [ ] Monthly visual inspections are documented by staff or automated with a digital checker.

- [ ] Extinguishers due for hydrostatic testing are scheduled within the allowed window and aligned with downtime.

- [ ] Recharge situations are tracked, with documentation and replacement parts in stock.

- [ ] Service reports and compliance certificates are stored in a central repository with easy access for audits.

- [ ] Your service provider offers a bundled annual service plan with transparent pricing and written SLAs.

Bold callouts for emphasis

- Key point: Hydrostatic testing is a regulated process with significant cost implications; proactive planning is essential.

- Pro tip: Consolidate to a single, trusted provider for easier budgeting and better service consistency.

- Warning: Delayed testing or poor documentation can lead to fines and increased liability in an emergency.

—

Horizontal rule

Citations and references

- OSHA 1910.157 – Portable Fire Extinguishers: Monthly visual inspections; annual maintenance; hydrostatic testing intervals depending on extinguisher type. [OSHA 1910.157 – Portable Fire Extinguishers](https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.157)

- Hydrostatic Testing Provision (2024 Rulemaking) – OSHA’s update on the burden hours and estimated operation/maintenance costs linked to hydrostatic testing provisions. [Hydrostatic Testing Provision of the Standard on Portable Fire Extinguishers – 2024 Rulemaking](https://www.osha.gov/laws-regs/federalregister/2024-01-09-0)

- Coast Guard regulation – Servicing of portable extinguishers, including NFPA 10-compliant servicing with certification. [Coast Guard regulations – 46 CFR 107.235](https://www.law.cornell.edu/cfr/text/46/107.235)

- NFPA 10 (Portable Fire Extinguishers) – Guiding standards for maintenance and testing, with detailed servicing guidance. [NFPA 10 – Portable Fire Extinguishers](https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=10)

Additional context and related standards (for researchers and procurement teams)

- NFPA 10 is the widely adopted industry standard for portable extinguishers, including recommended maintenance practices and testing intervals; ensure that your chosen service provider adheres to NFPA 10 guidelines and maintains current credentials. See NFPA 10 overview and standard details for reference. [NFPA 10 – Portable Fire Extinguishers](https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=10)

- For facilities with maritime components or Coast Guard-regulated environments, ensure that your service plan aligns with the CFR 107.235 requirements, including certification for servicing agencies. [Coast Guard regulations – 46 CFR 107.235](https://www.law.cornell.edu/cfr/text/46/107.235)

Conclusion

Maintaining fire extinguishers is a fundamental but nuanced area of facility management. The costs of maintenance, inspection, testing, recharging, and documentation accumulate over time, but they are essential investments in life safety, regulatory compliance, and operational continuity. By understanding the cost drivers, budgeting with bundled service plans, and selecting a partner with a proven track record, you can achieve a balance of safety, reliability, and cost efficiency. The right approach ensures your extinguishers will perform when needed, not just withstand an audit.

End with a clear call to action

If you’re ready to optimize your extinguisher maintenance program with a transparent, field-proven approach, reach out to 48Fire Protection to discuss a tailored annual service plan, including hydrostatic testing scheduling, documentation, and on-site maintenance.

[Contact 48Fire Protection](/contact-us)