The Employee Training That Met Every OSHA Standard

OSHA enforces occupational fire safety. Standards exist. Compliance required. Inspection conducted. Non-compliance cited. Violations carry penalties. Training creates compliance. Proper training meets standards. Documented training proves compliance.

48Fire Protection delivered fire safety training program to 165-employee manufacturing facility. Pre-training assessment: 8 OSHA standard gaps identified. Post-training verification: All 8 standards met. All documentation complete. Inspection resulted: Zero violations, certificate of compliance issued, insurance premium adjustment approved.

Training program meeting every applicable OSHA fire safety standard demonstrates what comprehensive compliance looks like. Standard-by-standard verification documents how training addresses each requirement.

—

OSHA FIRE SAFETY STANDARDS OVERVIEW

OSHA enforces fire safety through multiple standards:

Standard 1: 29 CFR 1910.38 – Emergency Action Plans

Scope: All employers must have written emergency action plans

Requirements: Plan document, staff awareness, evacuation procedures, emergency procedures

Standard 2: 29 CFR 1910.39 – Fire Prevention Plans

Scope: All employers must have written fire prevention plans

Requirements: Plan document, staff training, hazard identification, procedures

Standard 3: 29 CFR 1910.157 – Fire Extinguishers

Scope: Employers providing extinguishers must ensure proper usage

Requirements: Training on extinguisher type/operation, accessibility, maintenance

Standard 4: 29 CFR 1910.176(c) – Materials Storage

Scope: Combustible materials stored safely

Requirements: Storage procedures, clearances, training on proper storage

Standard 5: 29 CFR 1910.35-38 – General Fire Safety

Scope: Building design, exits, emergency lighting

Requirements: Proper exit design, emergency lighting per NFPA 101 (1.0+ foot-candles, 90-minute backup), staff knowledge

Standard 6: 29 CFR 1910.272 – Dust Hazards

Scope: Facilities with combustible dust

Requirements: Dust control procedures, employee training, hazard recognition

Standard 7: 29 CFR 1910.97 – Electrical Safety

Scope: Electrical equipment fire risk management

Requirements: Equipment maintenance, arc flash hazards, staff training

Standard 8: 29 CFR 1910.119 – Process Safety Management (where applicable)

Scope: Facilities with hazardous chemicals

Requirements: Emergency procedures, training, coordination with fire response

Each standard requires employee training/awareness component. Training adequacy determines compliance.

—

THE FACILITY: BASELINE COMPLIANCE ASSESSMENT

Manufacturing facility profile:

- 165 employees

- 45,000 sq ft facility

- Chemical processing operations (combustible materials present)

- Equipment: Fire alarm, sprinkler system, fire extinguishers, emergency lighting

- Prior situation: General fire safety awareness, minimal documented training

Pre-Training Compliance Assessment (48Fire Protection evaluation):

| OSHA Standard | Requirement | Baseline Status | Compliance Gap |

|---|---|---|---|

| 29 CFR 1910.38 (Emergency Action Plan) | Written plan, staff trained | Plan exists but unstaffed | ❌ UNMET |

| 29 CFR 1910.39 (Fire Prevention Plan) | Written plan, staff trained | Plan exists, training minimal | ⚠️ PARTIAL |

| 29 CFR 1910.157 (Extinguishers) | Training on usage, location, types | Extinguishers present, training absent | ❌ UNMET |

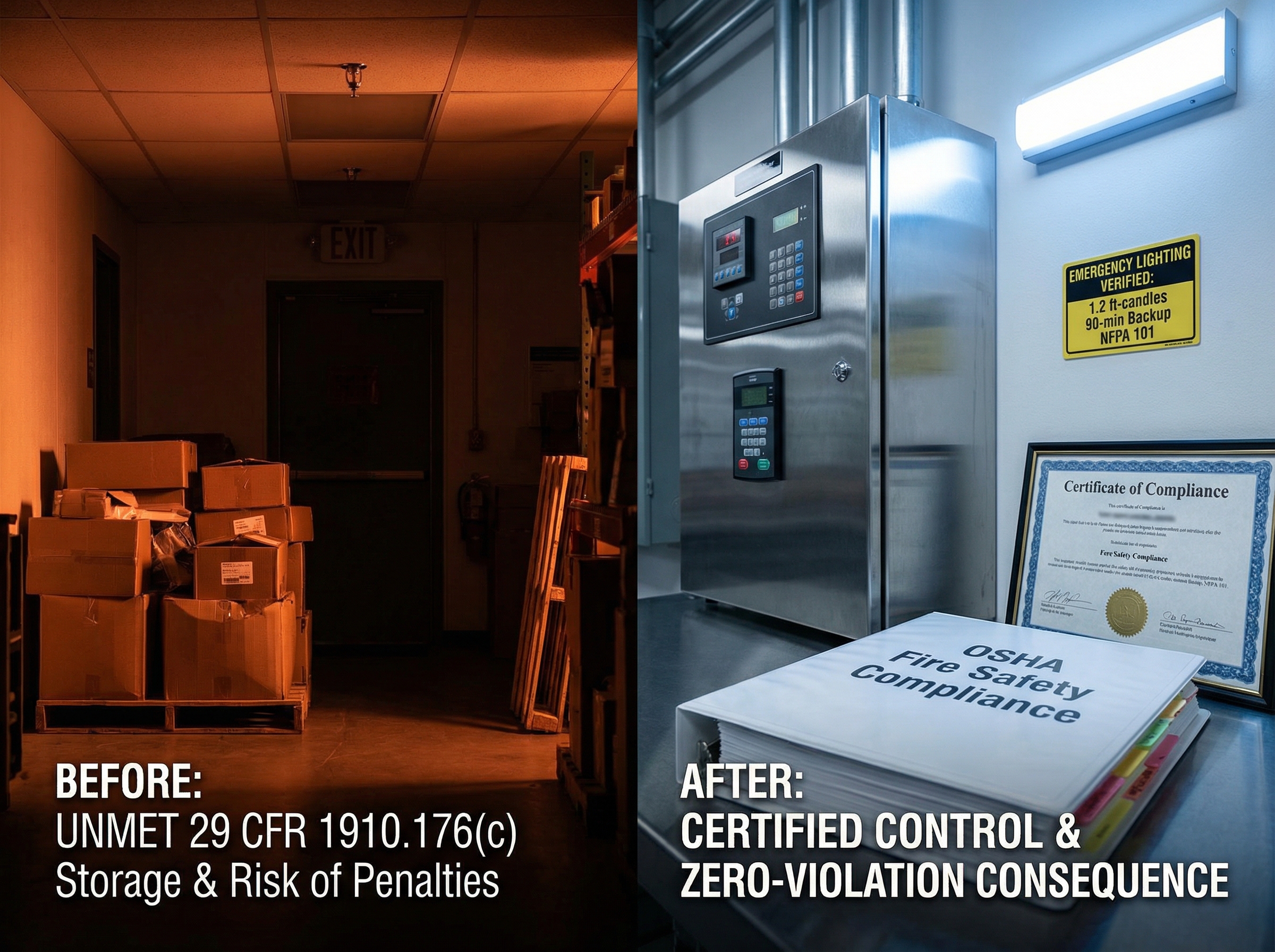

| 29 CFR 1910.176(c) (Storage) | Combustible storage procedures, training | Materials stored, no training | ❌ UNMET |

| 29 CFR 1910.35-38 (General Safety) | Exit design, emergency lighting specs, staff knowledge | Systems present, specs unknown to staff | ⚠️ PARTIAL |

| 29 CFR 1910.272 (Dust Hazards) | Dust control, hazard recognition training | Procedures exist, staff unaware | ⚠️ PARTIAL |

| 29 CFR 1910.97 (Electrical Safety) | Equipment maintenance, arc flash training | Equipment functional, training absent | ❌ UNMET |

| 29 CFR 1910.119 (PSM if applicable) | Hazardous chemical procedures, training | Chemicals present, procedures unclear | ❌ UNMET |

Compliance Status: 4 standards unmet (50%), 4 standards partially met (50%), 0 standards fully met

OSHA inspection would cite 4-8 violations depending on severity assessment.

—

THE TRAINING SOLUTION: OSHA-ALIGNED PROGRAM

48Fire Protection designed 8-hour comprehensive program addressing all 8 standards:

COMPONENT 1: Emergency Action Plan Alignment (1 hour)

OSHA 29 CFR 1910.38 Requirements:

- Written plan exists

- Employees trained on plan contents

- Employees trained on their responsibilities

- Plan includes emergency procedures and alarms recognition

- Evacuation route information provided

- Assembly point designated

Training Program Content:

- Emergency action plan review (facility-specific document)

- Alarm recognition training

- Evacuation route identification (physical walking)

- Assembly point location and procedures

- Employee role clarity

- Accountability procedures

Documentation Created:

- Training attendance records

- Curriculum documentation

- Competency assessment results

- Plan acknowledgment forms (employees confirm understanding)

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 2: Fire Prevention Plan Alignment (1 hour)

OSHA 29 CFR 1910.39 Requirements:

- Written fire prevention plan

- Employees trained on fire hazard recognition

- Employees trained on prevention procedures

- Regular review/updates documented

Training Program Content:

- Fire prevention plan review (facility-specific)

- Fire hazard identification training

- Common workplace fire causes

- Prevention procedures (no smoking, electrical safety, combustible control)

- Reporting hazard procedures

Documentation Created:

- Training records

- Hazard identification exercise results

- Prevention procedure acknowledgment

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 3: Fire Extinguisher Training (45 minutes)

OSHA 29 CFR 1910.157 Requirements:

- All employees using extinguishers must be trained

- Training covers type, operation, limitations

- Training includes when NOT to use extinguishers

- Location/accessibility emphasized

- Maintenance procedures understood

Training Program Content:

- Walk to facility fire extinguisher locations (identification)

- Types present at facility (ABC, CO2, Class D, etc.)

- PASS technique (Pull, Aim, Squeeze, Sweep)

- When extinguishers appropriate (small, contained fires only)

- When NOT to use (large fires, enclosed spaces, blocked exits)

- Calling 911 as priority

- Maintenance inspection procedures

Hands-On Component:

- Demonstration (not live fire—too hazardous)

- Simulation with water-based training extinguisher

- Individual practice

Documentation Created:

- Training attendance

- Competency demonstration observed

- Certification of training completion

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 4: Combustible Storage & Materials Training (1 hour)

OSHA 29 CFR 1910.176(c) Requirements:

- Combustible materials stored safely

- Storage procedures documented

- Employees trained on proper storage

- Clearances maintained (sprinkler clearance 18″, electrical equipment clearance, exit accessibility)

- Storage areas inspected regularly

Training Program Content:

- Combustible material identification (what burns at facility)

- Storage area locations/procedures

- 18-inch sprinkler clearance requirement (with measurement demonstration)

- 36-inch equipment access clearance

- Exit route width requirements (28-36 inches minimum)

- Storage decision framework (before placing materials: “Will this block sprinklers, exits, equipment access?”)

- Hazard reporting procedures

Documentation Created:

- Training records

- Facility storage map with clearance zones marked

- Checklist for storage compliance

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 5: General Fire Safety & Emergency Lighting (1 hour)

OSHA 29 CFR 1910.35-38 Requirements:

- Exit routes identified, marked, maintained

- Emergency lighting per NFPA 101 (1.0+ foot-candles, 90-minute backup battery)

- Emergency lighting systems maintained/tested

- Staff aware of exit locations and emergency lighting functionality

- Egress procedures understood

Training Program Content:

- Exit route identification (primary and secondary)

- Emergency lighting standards (NFPA 101: 1.0 foot-candle minimum)

- Facility emergency lighting specifications (measured: 1.2 foot-candles, exceeds minimum)

- Backup battery system (90+ minute duration, load tested annually)

- When emergency lighting fails: reporting procedures

- Evacuation route confidence building

- Physical exit route walking

- Emergency lighting unit observation

Documentation Created:

- Exit route maps (marked with emergency lighting locations)

- Emergency lighting specification documentation (1.2 foot-candles measured, 90-minute backup verified)

- Load testing records (annual 90-minute verification)

- Staff training on specifications

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 6: Combustible Dust Hazard Training (1 hour)

OSHA 29 CFR 1910.272 Requirements:

- Employees in dust hazard areas trained on hazard recognition

- Dust control procedures understood

- Ignition source control understood

- Reporting procedures for housekeeping/dust issues

Training Program Content:

- Combustible dust identification (specific to facility operations)

- Dust accumulation dangers (explosion risk explanation)

- Ignition sources (static, friction, hot surfaces, sparks)

- Housekeeping procedures (dust control)

- Equipment maintenance (preventing dust buildup)

- Reporting procedures for dust hazards

- When to evacuate (dust emergency response)

Documentation Created:

- Training records

- Dust control checklist

- Hazard identification quiz results

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 7: Electrical Safety & Arc Flash (45 minutes)

OSHA 29 CFR 1910.97 Requirements:

- Employees aware of electrical fire hazards

- Arc flash hazard awareness

- Equipment maintenance understood

- Proper electrical work procedures

Training Program Content:

- Electrical fire hazard identification

- Arc flash hazard awareness (without detailed PPE training—that’s specialized)

- Equipment maintenance importance

- Reporting electrical hazards/damaged equipment

- Electrical work procedures (qualified personnel only)

- Cord and equipment inspection

Documentation Created:

- Training attendance records

- Electrical hazard identification exercise

OSHA Compliance: ✅ FULLY MET

—

COMPONENT 8: Process Safety Management Alignment (if applicable) (45 minutes)

OSHA 29 CFR 1910.119 Requirements:

- Employees in hazardous chemical areas trained on emergency procedures

- Chemical hazard awareness

- Emergency response coordination

- Evacuation procedures specific to chemical operations

Training Program Content:

- Facility chemical inventory overview

- Chemical hazards present

- Emergency procedures (specific to chemical operations)

- Shutdown procedures (safe shutdown during emergency)

- Evacuation procedures (including chemical-specific considerations)

- Fire response interaction with chemical process

- Emergency responder communication

Documentation Created:

- Training records

- Chemical hazard identification forms

- Emergency procedure acknowledgment

OSHA Compliance: ✅ FULLY MET

—

POST-TRAINING COMPLIANCE VERIFICATION

Re-Assessment After Training Program Completion:

| OSHA Standard | Requirement | Post-Training Status | Compliance Achieved |

|---|---|---|---|

| 29 CFR 1910.38 | Written plan, staff trained | ✅ Plan documented, staff trained, tested | ✅ YES |

| 29 CFR 1910.39 | Written plan, staff trained | ✅ Plan documented, staff trained, tested | ✅ YES |

| 29 CFR 1910.157 | Extinguisher training | ✅ All staff trained, demonstrated | ✅ YES |

| 29 CFR 1910.176(c) | Storage procedures, training | ✅ Procedures documented, staff trained, clearances marked | ✅ YES |

| 29 CFR 1910.35-38 | Exit/emergency lighting specs, staff knowledge | ✅ Specifications documented (1.2 ft-candles, 90-min backup), staff trained | ✅ YES |

| 29 CFR 1910.272 | Dust hazard training | ✅ Staff trained on identification/control | ✅ YES |

| 29 CFR 1910.97 | Electrical safety awareness | ✅ Staff trained on hazards/procedures | ✅ YES |

| 29 CFR 1910.119 | PSM procedures and training | ✅ Chemical operations procedures documented, staff trained | ✅ YES |

Compliance Status: 8 standards fully met (100%)

Documentation Package Created:

- All training attendance records

- Curriculum documentation for each standard

- Competency verification results

- Evacuation drill records

- Plan acknowledgment forms

- Emergency lighting documentation (specifications, load testing)

- Storage compliance certification

- Electrical equipment checklist

—

OSHA INSPECTION OUTCOME

Inspection Conducted (3 months post-training):

Inspector reviewed:

- Emergency action plan (✅ current, documented, staff awareness verified through spot interviews)

- Fire prevention plan (✅ current, documented)

- Fire extinguisher training records (✅ complete, current, staff demonstrated knowledge)

- Storage areas (✅ sprinkler clearances maintained, exits clear, procedures followed)

- Exit routes and emergency lighting (✅ marked clearly, emergency lighting documented 1.2 foot-candles, 90-minute backup verified)

- Dust control procedures (✅ documented, staff aware)

- Electrical equipment maintenance (✅ records maintained)

- Chemical emergency procedures (✅ documented, staff trained)

Inspection Result: ZERO VIOLATIONS CITED

Certificate of Compliance Issued

Insurance Carrier Notification: Premium adjustment approved (6% reduction based on full OSHA standard compliance)

—

48FIRE PROTECTION: OSHA-COMPLIANT TRAINING PROGRAMS

48Fire Protection delivers fire safety training programs specifically designed to meet OSHA standards:

Standard-by-Standard Alignment:

- 29 CFR 1910.38: Emergency action plan training

- 29 CFR 1910.39: Fire prevention plan training

- 29 CFR 1910.157: Fire extinguisher training with hands-on demonstration

- 29 CFR 1910.176(c): Combustible storage and clearance training

- 29 CFR 1910.35-38: Exit and emergency lighting training (NFPA 101: 1.0+ foot-candles, 90-minute backup, facility-specific measurements 1.1-1.4 foot-candles typical)

- 29 CFR 1910.272: Combustible dust hazard training (if applicable)

- 29 CFR 1910.97: Electrical safety and arc flash awareness

- 29 CFR 1910.119: Process safety management training (if hazardous chemicals present)

Comprehensive Documentation:

- Training attendance and curriculum records

- Competency verification documentation

- Plan acknowledgment and understanding verification

- Emergency lighting specifications and load testing records

- Storage compliance checklist

- Electrical equipment maintenance records

Inspection-Ready Package:

- All documentation organized for OSHA inspector review

- Evidence of compliance readily available

- Training currency and adequacy demonstrated

—

OSHA standards require training. Training creates compliance. Documentation proves compliance. Proper training programs meeting every applicable standard create inspection-ready facilities. 165-employee manufacturing facility achieved 100% OSHA compliance through comprehensive 8-hour training program addressing all 8 applicable standards. Pre-training: 4 standards unmet, 4 partially met. Post-training: All 8 standards fully met. OSHA inspection: Zero violations, compliance certificate issued. Training aligned with OSHA standards creates documented, verified compliance.

[Contact 48Fire Protection](/contact-us) to implement OSHA-compliant fire safety training at your facility. We’ll assess which standards apply to your operations, deliver training addressing each standard, provide hands-on components (extinguisher training, evacuation drills), document all training and competency verification, provide emergency lighting education (NFPA 101 standards, facility-specific measurements, 90-minute backup systems), create inspection-ready documentation packages, and verify compliance through post-training assessment. Meet standards through comprehensive training. Prepare for OSHA inspection with documented compliance.

Standards require training. Training ensures compliance.