What Every Facility Should Know About Expired Extinguishers

—

THE QUESTION THAT STARTED A $23,000 PROBLEM

Facility manager examining fire extinguisher: “Does this expire?”

Equipment purchased 2008. Mounted in hallway 17 years. Clean appearance. Gauge showing green. No obvious damage. Annual service tags present.

Manager assumed: “Fire extinguishers don’t expire if maintained properly.”

Fire marshal annual inspection revealed different reality: 32 extinguishers requiring immediate fire extinguisher hydrostatic testing, 8 years overdue.

The conversation:

“These units are significantly past testing deadlines. NFPA 10 Table 8.3.1 requires fire extinguisher hydrostatic testing every 12 years for dry chemical types. Your equipment hasn’t been tested since installation.”

“But they’re maintained annually. Service tags are current. Gauges show proper pressure.”

“Annual maintenance doesn’t substitute for fire extinguisher hydrostatic testing. Testing verifies pressure vessel structural integrity. Without testing, we cannot confirm these units are safe for continued use.”

Citation issued. 60-day correction required.

Emergency correction costs:

- Expedited fire extinguisher hydrostatic testing: 32 units @ $95 = $3,040

- Failed testing replacements: 18 units @ $245 = $4,410

- Citation penalty: $1,500

- Follow-up inspection: $350

- Rushed scheduling premium: $800

- Management response time: 40 hours

Total: $10,100 plus management time

The preventable cost: Scheduled fire extinguisher hydrostatic testing would have cost $4,200 spread over 2-3 years with standard rates and planned replacements.

The expensive lesson: Fire extinguishers don’t “expire” with dates stamped on them—but they do require periodic fire extinguisher hydrostatic testing to verify continued safe operation.

This article clarifies what facilities must know about fire extinguisher hydrostatic testing requirements, equipment service life limits, and when replacement becomes mandatory.

—

UNDERSTANDING “EXPIRATION” VS. TESTING REQUIREMENTS

Do Fire Extinguishers Actually Expire?

The direct answer: Fire extinguishers don’t have traditional expiration dates, but they do have testing deadlines and practical service life limits.

What fire extinguishers DON’T have:

- Stamped expiration dates like food products

- Manufacturer-specified “use by” dates

- Automatic replacement deadlines

- Agent expiration (for most types)

What fire extinguishers DO have:

- Mandatory fire extinguisher hydrostatic testing intervals per NFPA 10 Table 8.3.1

- Six-year internal examination requirements per NFPA 10 Section 7.3.1

- Annual maintenance requirements per Section 7.3

- Practical service life limits (typically 12-20 years depending on type and conditions)

—

NFPA 10 Fire Extinguisher Hydrostatic Testing Requirements

NFPA 10 Table 8.3.1 specifies testing intervals:

| Extinguisher Type | Hydrostatic Test Interval |

|---|---|

| Water (stored pressure) | 5 years |

| Foam (stored pressure) | 5 years |

| Wet chemical | 5 years |

| Carbon dioxide | 5 years |

| Dry chemical (stored pressure) | 12 years |

| Halogenated agent | 12 years |

| Clean agent | 12 years |

These aren’t expiration dates—they’re mandatory structural testing deadlines.

NFPA 10 Section 8.1 states:

“Hydrostatic testing is a means to periodically determine that a fire extinguisher’s pressure vessel is safe for continued use.”

Critical distinction: Fire extinguisher hydrostatic testing verifies structural integrity, not agent effectiveness or general maintenance status.

—

What Fire Extinguisher Hydrostatic Testing Actually Tests

Testing procedure per NFPA 10 Section 8:

Step 1: Complete discharge and disassembly

- Remove all extinguishing agent

- Disassemble valve assembly

- Remove all internal components

- Prepare vessel for testing

Step 2: Internal visual examination

- Inspect interior walls for corrosion

- Check for pitting, rust, deterioration

- Look for structural damage

- Assess overall condition

Step 3: Pressure vessel testing

- Fill vessel with water or approved fluid

- Pressurize to test pressure (typically 1.5-3x operating pressure per manufacturer specifications)

- Hold pressure for required time period

- Monitor for leaks, deformation, structural failure

Step 4: Pass/fail determination

If passed:

- Vessel shows no leaks during pressure hold

- No deformation observed

- Internal condition acceptable

- Unit can return to service after recharge

If failed:

- Vessel leaks under test pressure

- Deformation observed (bulging, stress)

- Internal corrosion excessive

- Unit must be destroyed per NFPA 10 Section 8.3.5

Critical requirement: “Extinguishers that fail the hydrostatic test or are found to have serious defects shall be destroyed or recycled at a scrap metal facility. Such extinguishers shall not be returned to service.”

Failed units cannot be repaired—only replaced.

—

COMMON MISCONCEPTIONS ABOUT EXPIRATION

Myth 1: “Annual Maintenance Means It Doesn’t Expire”

The belief: “We have annual maintenance. Service tags are current. Equipment is maintained properly. Therefore it doesn’t expire.”

The reality: Annual maintenance per NFPA 10 Section 7.3 and fire extinguisher hydrostatic testing per Section 8 are separate, distinct requirements.

Annual maintenance includes:

- External examination

- Internal component examination (where accessible)

- Seal and O-ring replacement

- Recharge if needed

- Service tag application

Annual maintenance DOES NOT include:

- Internal pressure vessel examination

- Structural integrity testing

- Pressure vessel testing under test pressure

- Verification of continued safe operation under extreme conditions

Fire extinguisher hydrostatic testing specifically verifies:

- Pressure vessel structural integrity

- Ability to safely contain operating pressure

- No internal corrosion compromising vessel strength

- Vessel can withstand pressures exceeding normal operation

Both requirements must be satisfied—annual maintenance doesn’t eliminate fire extinguisher hydrostatic testing requirements.

—

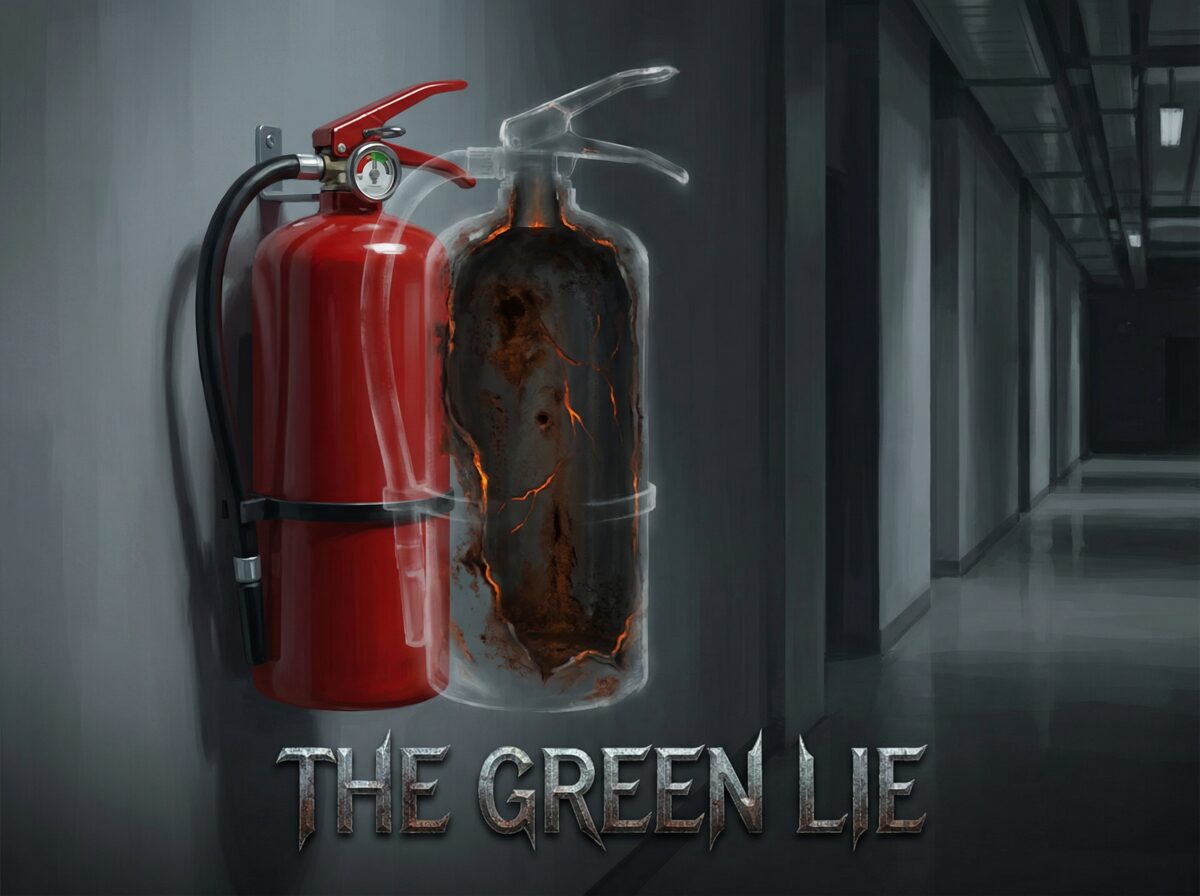

Myth 2: “If Gauge Shows Green, It’s Still Good”

The belief: “Pressure gauge reads in green zone. Equipment appears functional. Must still be good regardless of age.”

The reality: Gauge reading indicates current pressure status—not structural vessel integrity, agent condition, or fire extinguisher hydrostatic testing compliance.

What green gauge indicates:

- Pressure currently in acceptable range

- Vessel currently holding pressure

- Equipment may discharge if activated

What green gauge DOESN’T indicate:

- Pressure vessel structural integrity

- Internal corrosion status

- Component condition

- Agent quality or quantity

- Fire extinguisher hydrostatic testing compliance

- Whether unit would function effectively during fire

Representative scenario:

Unit manufactured 2006. Dry chemical stored pressure. Never tested (18 years since manufacture, 6 years overdue for fire extinguisher hydrostatic testing per 12-year requirement).

External appearance: Perfect

Gauge reading: Green zone

Service tags: Current annual maintenance

Internal reality: Significant corrosion on 40% of interior surfaces

When finally tested: Failed immediately—vessel deformation under test pressure. Unit destroyed per NFPA requirements.

Green gauge gave false confidence. Fire extinguisher hydrostatic testing revealed structural failure invisible externally.

—

Myth 3: “They Last Forever If You Take Care of Them”

The belief: “Fire extinguishers are steel pressure vessels. With proper maintenance, they last indefinitely.”

The reality: Even with excellent maintenance including proper fire extinguisher hydrostatic testing, equipment has practical service life limits.

Industry data from certified testing facilities:

First test cycle (5-12 years):

- Failure rate: 8-15%

- Primary failure: Manufacturing defects, early corrosion

Second test cycle (10-24 years):

- Failure rate: 20-30%

- Primary failure: Progressive internal corrosion

Third test cycle (15-36 years):

- Failure rate: 35-55%

- Primary failure: Advanced corrosion, metal fatigue

Equipment 20+ years:

- Failure rate: 60-80%

- Primary failure: Vessel structural deterioration

Even units passing multiple fire extinguisher hydrostatic testing cycles eventually fail due to:

- Accumulated metal fatigue from pressure cycling

- Progressive internal corrosion despite maintenance

- Seal interface degradation allowing moisture ingress

- Component obsolescence making parts unavailable

- Cost of continued testing exceeding replacement value

Typical practical service life with proper maintenance and testing: 12-20 years depending on type, environment, and testing outcomes.

—

WHEN REPLACEMENT BECOMES MANDATORY

Absolute Replacement Requirements

Fire extinguishers must be replaced when:

1. Failed fire extinguisher hydrostatic testing

NFPA 10 Section 8.3.5 is unambiguous: Units failing testing must be destroyed and recycled. No repair possible. Immediate replacement required.

2. Serious defects identified during testing

Section 8.3.5 also applies to units with serious defects found during examination:

- Extensive internal corrosion

- Structural damage to vessel

- Severe external corrosion affecting integrity

- Damage from fire exposure

- Evidence of vessel abuse or misuse

3. Obsolete or discontinued equipment

When manufacturers discontinue models:

- Parts become unavailable

- Service becomes impossible

- Fire extinguisher hydrostatic testing may not be feasible

- Replacement necessary

4. Equipment recalls

Manufacturer safety recalls require:

- Immediate removal from service

- Replacement per recall instructions

- No continued use permitted

—

When Replacement Makes Economic Sense

Even when not mandatory, replacement may be cost-effective:

Age-based economics:

Equipment 15+ years old approaching fire extinguisher hydrostatic testing:

- Testing cost: $50-75 per unit

- Recharge cost: $35-50 per unit

- Failure probability: 35-55%

- Replacement if failed: $180-350 per unit

Expected cost for 20 units (15+ years old):

- Testing all units: $1,000-1,500

- Recharging passed units: $315-675 (45% pass rate)

- Replacing failed units: $1,980-3,850 (55% fail rate)

- Total: $3,295-6,025

vs. Proactive replacement:

- Replace all 20 units: $3,600-7,000

- Avoid testing costs

- All new equipment with full service life

- No mixed-age inventory

- Predictable budget

When units 15+ years old, proactive replacement often costs same or less than testing program with high failure rates.

—

FIRE EXTINGUISHER HYDROSTATIC TESTING PROCESS

What Facilities Should Expect

Step 1: Equipment removal

48Fire fire extinguisher hydrostatic testing process:

- Schedule testing visit

- Remove units requiring testing

- Document serial numbers and locations

- Photograph units before removal

- Install temporary replacement units

- Transport to certified testing facility

No gap in fire protection during testing.

—

Step 2: Testing facility procedures

Complete examination and testing:

- Full discharge of extinguishing agent

- Valve assembly removal

- Internal visual examination

- Vessel cleaning if needed

- Fill with testing fluid (typically water)

- Pressurize to test pressure per manufacturer specifications

- Hold pressure for required duration

- Visual inspection during pressurization

- Depressurize and examine

- Pass/fail determination

Time per unit: 45-75 minutes including preparation and documentation

—

Step 3: Post-test processing

For units passing fire extinguisher hydrostatic testing:

- Complete interior drying

- Internal component inspection

- New seals and O-rings installed

- Valve assembly reinstalled with new components

- Recharge with proper agent type and quantity

- New service tag applied documenting test date

- Return to facility

For units failing testing:

- Unit destroyed per NFPA 10 Section 8.3.5

- Documentation of failure and destruction

- Replacement unit provided

- Original unit disposal certified

- Facility notified of failure and replacement

—

Step 4: Reinstallation

- Tested/replacement units returned to facility

- Installed in original locations

- Temporary units removed

- Complete documentation provided

- Digital records updated

- Next testing due date calculated and scheduled

Typical timeline: 5-10 business days from removal to reinstallation

—

Fire Extinguisher Hydrostatic Testing Costs

Realistic cost expectations:

Per unit costs:

- Testing service: $50-75

- Recharge after passing: $35-50

- Replacement if failed: $180-350

- Transport and handling: Typically included

Total per unit:

- If passed: $85-125

- If failed: $180-350

Facility planning (100 dry chemical units, 12-year testing cycle):

Year 12 (first testing):

- 100 units tested: $5,000-7,500

- 15 units failed and replaced: $2,700-5,250

- 85 units recharged: $2,975-4,250

- Total Year 12: $10,675-17,000

Year 24 (second testing, remaining 85 units):

- 85 units tested: $4,250-6,375

- 30 units failed and replaced: $5,400-10,500

- 55 units recharged: $1,925-2,750

- Total Year 24: $11,575-19,625

Annual budget planning:

- Average 8-9 units tested per year

- Budget $850-1,500 annually for testing program

- Budget $500-1,000 annually for replacements

—

CONSEQUENCES OF IGNORING FIRE EXTINGUISHER HYDROSTATIC TESTING

Regulatory Violations

Fire marshal citations for overdue testing:

Typical pattern:

- Annual inspection identifies units overdue for fire extinguisher hydrostatic testing

- Citation issued with correction deadline (30-90 days typical)

- Penalty assessment: $500-2,000 per citation

- Follow-up inspection required: $250-500

- Expedited testing charges: +$25-45 per unit premium

- Management response time: Significant

Representative costs:

- 40 units overdue for testing

- Citation penalty: $1,200

- Expedited testing premium: $1,000-1,800

- Follow-up inspection: $350

- Total: $2,550-3,350 beyond normal testing costs

—

Insurance Complications

Impact on coverage and claims:

During property insurance renewal:

Carrier assessment identifies:

- Fire extinguisher hydrostatic testing significantly overdue

- NFPA 10 compliance questionable

- Fire protection equipment reliability uncertain

Premium impact:

- Surcharge for fire protection deficiency: 15-25%

- For $500,000 property coverage with $15,000 base premium

- Additional cost: $2,250-3,750 annually until corrected

During fire damage claim:

Investigation examines fire protection maintenance:

- Fire extinguisher hydrostatic testing records requested

- Testing significantly overdue discovered

- Equipment reliability questioned

- Maintenance negligence potential

Claim complications:

- Processing delays

- Additional investigation

- Potential coverage reductions

- Possible partial denial based on maintenance inadequacy

—

Safety Risk

Equipment failure during actual fire emergency:

Without proper fire extinguisher hydrostatic testing:

Internal corrosion weakens pressure vessel. Normal operating pressure contained. Unit appears functional. Employee attempts use during fire.

Potential failures:

- Weak discharge (insufficient pressure due to undetected leaks)

- Component failure (degraded valve or hose)

- Vessel rupture (extreme case—vessel fails under discharge pressure)

- Agent contamination (moisture-damaged agent doesn’t suppress fire effectively)

Result: Fire not controlled. Property damage. Potential injuries. Liability exposure.

With proper fire extinguisher hydrostatic testing:

Structural integrity verified. Internal corrosion detected before failure. Failed units replaced. Equipment reliability confirmed. Fire suppression capability assured.

—

IMPLEMENTING PROPER TESTING PROGRAMS

Systematic Fire Extinguisher Hydrostatic Testing

48Fire systematic approach prevents “expiration” problems:

Step 1: Complete equipment audit

- Document all equipment (types, locations, serial numbers)

- Record manufacturing dates

- Identify last testing dates

- Calculate testing due dates per NFPA 10 Table 8.3.1

- Determine current compliance status

Step 2: Prioritized testing schedule

- Identify overdue equipment (immediate priority)

- Schedule approaching deadlines (next 12 months)

- Plan future testing (2-5 year forecast)

- Budget allocation recommendations

Step 3: Automated deadline tracking

- Digital system calculates testing due dates automatically

- Notifications 6-12 months before deadlines

- Prevents testing deadlines from being missed

- Ensures continuous NFPA compliance

Step 4: Scheduled testing coordination

- Testing scheduled before deadlines

- Standard rates (no expedited charges)

- Temporary equipment during testing

- Planned replacement budgeting

- No regulatory violations

—

Budget Planning for Testing

Realistic budget allocation:

Small facility (25-50 units):

- Annual testing budget: $400-800

- Annual replacement budget: $300-600

- Total annual: $700-1,400

Medium facility (50-150 units):

- Annual testing budget: $800-2,000

- Annual replacement budget: $600-1,500

- Total annual: $1,400-3,500

Large facility (150+ units):

- Annual testing budget: $2,000-4,500

- Annual replacement budget: $1,500-3,500

- Total annual: $3,500-8,000

Budget planning prevents:

- Emergency testing expenses

- Rushed replacement costs

- Violation penalties

- Insurance complications

- Management crisis response

—

WHAT FACILITIES MUST KNOW

Critical Understanding Points

1. Fire extinguishers don’t “expire” but require fire extinguisher hydrostatic testing

No stamped expiration dates exist. Mandatory testing intervals per NFPA 10 Table 8.3.1 determine when structural verification required.

2. Testing intervals are mandatory, not optional

NFPA 10 Section 8 requirements are regulatory standards enforced by fire marshals, OSHA, and insurance carriers.

3. Annual maintenance doesn’t substitute for testing

Separate requirements. Both must be satisfied. Annual maintenance per Section 7.3 + fire extinguisher hydrostatic testing per Section 8.

4. Failed testing means mandatory replacement

NFPA 10 Section 8.3.5 requires destroyed failed units. No repair permitted. Replacement only option.

5. Practical service life is 12-20 years

Even with proper maintenance and passing testing, equipment eventually reaches end of practical service life due to accumulated wear and increasing failure probability.

6. Systematic testing prevents costly violations

Scheduled fire extinguisher hydrostatic testing before deadlines prevents citations, expedited charges, and regulatory complications.

7. Budget planning is essential

Annual testing and replacement costs are predictable with proper planning. Emergency corrections cost 2-3x more than scheduled testing.

—

CONCLUSION

Fire extinguishers don’t have traditional expiration dates, but they do require:

Mandatory fire extinguisher hydrostatic testing per NFPA 10 Table 8.3.1:

- Water/foam/wet chemical/CO2: 5-year intervals

- Dry chemical/halogenated/clean agent: 12-year intervals

Purpose of fire extinguisher hydrostatic testing:

- Verify pressure vessel structural integrity

- Detect internal corrosion before failure

- Ensure continued safe operation

- Determine pass/fail status for continued service

Critical requirements:

- Testing separate from annual maintenance (both required)

- Failed units must be destroyed and replaced per NFPA 10 Section 8.3.5

- Testing deadlines are mandatory regulatory requirements

- Practical service life typically 12-20 years with proper testing

Cost implications:

- Scheduled testing: $85-125 per unit if passed

- Failed replacement: $180-350 per unit

- Emergency testing: +$25-45 per unit premium

- Regulatory violations: $2,550-3,350 beyond testing costs

- Insurance complications: $2,250-3,750 annual premium impact

Systematic fire extinguisher hydrostatic testing prevents:

- Regulatory violations and penalties

- Insurance complications and premium increases

- Equipment failure during emergencies

- Emergency correction costs

- Budget surprises

48Fire systematic fire extinguisher hydrostatic testing programs provide automated deadline tracking, scheduled testing before NFPA deadlines, temporary equipment during testing, complete documentation, and predictable budgeting—ensuring facilities maintain compliant, reliable fire protection equipment without “expiration” surprises.

[Schedule Fire Extinguisher Hydrostatic Testing Assessment](/contact-us)

—

48Fire

Fire Extinguisher Hydrostatic Testing

NFPA-Certified Testing Facilities • Systematic Scheduling • Nationwide

Contact: [/contact-us](/contact-us)