What 2,000 Businesses Learned from Alarm Testing Errors

The Testing Mistake That Shows Up Everywhere

Fire protection contractors see the same errors repeated across thousands of buildings.

Not because property managers are careless. Not because maintenance staff are incompetent. But because certain fire alarm testing procedures have confusing requirements that trip up even experienced professionals.

The data source:

Analysis based on fire alarm inspection reports, contractor service records, and fire marshal violation notices collected from commercial buildings between 50,000-150,000 square feet. The patterns reveal what consistently goes wrong during fire alarm testing—and more importantly, how to prevent these problems.

Most common testing errors by category:

- Documentation problems: 42% of testing issues

- Device testing procedure mistakes: 31% of issues

- Timing and frequency errors: 18% of issues

- Equipment and tool problems: 9% of issues

Why this matters:

Testing errors don’t just cause failed inspections. They create real problems:

- Code violations requiring expensive emergency corrections

- Undetected equipment failures compromising fire protection

- False confidence in systems that won’t work properly during fires

- Wasted money on incorrect testing procedures

Understanding common mistakes helps avoid them. Here’s what actually happens during fire alarm testing across thousands of commercial buildings.

—

Documentation Errors: The Most Common Problem

Testing might be perfect, but without proper documentation, inspectors write violations anyway.

Missing test dates and technician signatures

NFPA 72 Section 7.7.2 requires documentation include date, time, and identity of person performing testing. Sounds simple—but gets missed constantly.

What happens:

Technician tests all 347 devices in building. Writes summary report: “Annual inspection completed. All devices tested and functional.” Signs report, files it away.

Fire marshal arrives six months later. Asks to see device-by-device test results. Report only has summary statement—no individual device documentation.

The violation: Inadequate documentation. Inspector can’t verify every device was actually tested.

Why it happens:

Testing 300+ devices takes hours. Technician focuses on physical testing work, rushing through paperwork at the end. Summary seems sufficient until inspector requests detailed records.

The fix:

Use device testing checklist capturing:

- Device address or location

- Test date and time

- Test method used

- Pass/fail result

- Technician initials

Pre-printed forms or spreadsheets ensure nothing gets missed. Many addressable fire alarm panels generate automatic testing reports including all required information.

Incomplete sensitivity testing records

Smoke detectors over 10 years old require sensitivity testing per NFPA 72 Section 14.4.5.3.5.

What happens:

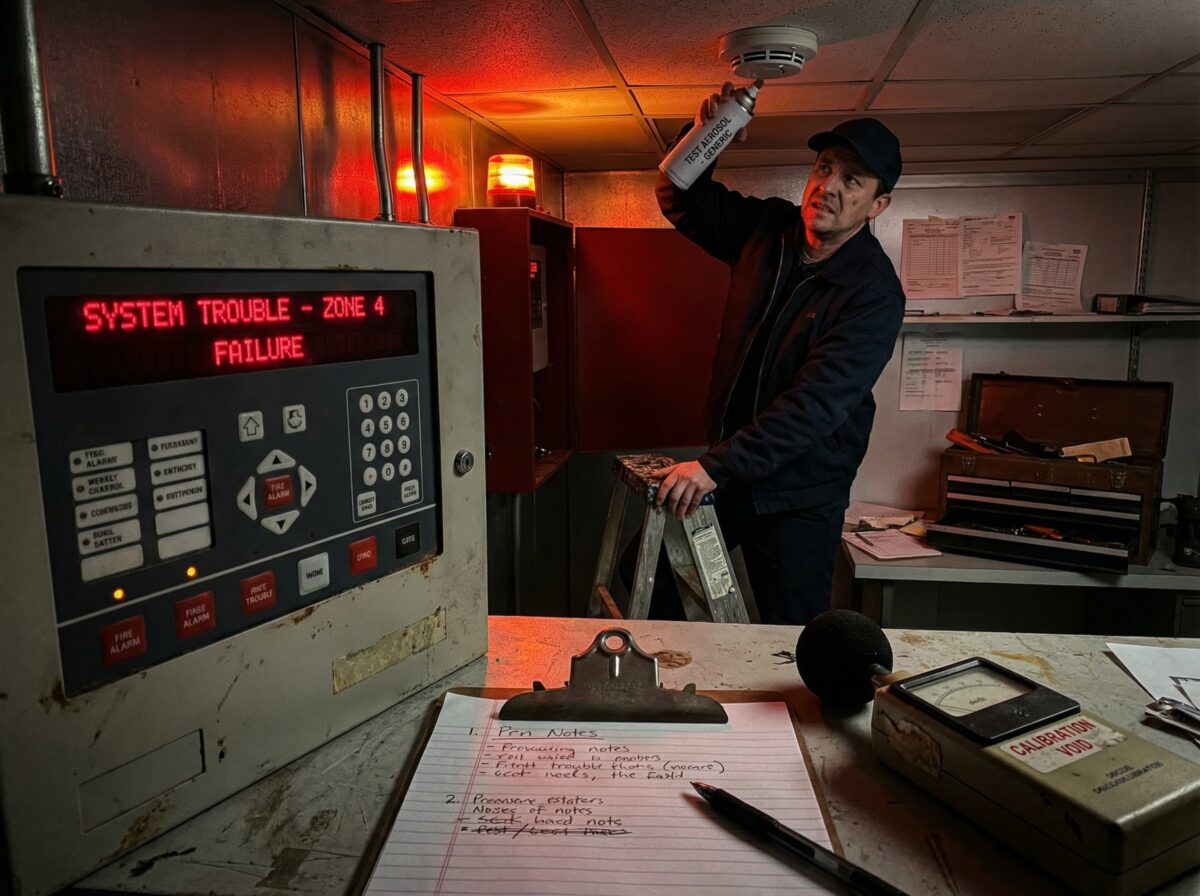

Contractor tests smoke detectors using magnet or aerosol confirming each detector activates. Records show “Device 142 – tested, passed.”

Inspector asks for sensitivity measurements showing detector operates within listed range (typically 0.5% to 4.0% obscuration per foot). Test records don’t include these measurements.

The violation: Sensitivity testing incomplete. Activation test confirms detector works but doesn’t verify sensitivity within acceptable range.

Why it happens:

Sensitivity testing requires specialized equipment measuring exact obscuration levels triggering alarms. Basic activation testing is faster and seems adequate—but doesn’t meet code requirements for older detectors.

The fix:

Track detector installation dates. When detectors reach 10 years old, schedule proper sensitivity testing using calibrated equipment. Document obscuration percentage at which each detector activates.

For addressable systems, many panels display sensitivity measurements during testing. Print these reports as documentation rather than just recording pass/fail.

Missing sound pressure measurements

NFPA 72 requires audible notification devices meet minimum sound levels: 75 dBA in sleeping areas, 15 dBA above ambient in other areas (Section 18.4.3).

What happens:

Technician activates fire alarm, walks through building confirming horns sound loud enough. Documents “All notification devices audible throughout building.”

Inspector requests decibel measurements proving compliance. Records don’t contain actual dBA readings.

The violation: No sound pressure level documentation. Subjective assessment doesn’t satisfy code requirements.

Why it happens:

Decibel meters cost $100-400. Smaller contractors may not own proper testing equipment. Even when available, taking measurements at required locations throughout building adds significant time to inspections.

The fix:

Annual comprehensive inspections must include actual sound pressure measurements using calibrated decibel meter. Measure at:

- Farthest point from any notification device in each room

- Pillow height in sleeping areas (if applicable)

- Background ambient levels for comparison

Document readings on floor plan showing measurement locations and dBA values. This documentation proves code compliance rather than relying on subjective judgment.

Inadequate photographic documentation

Fire marshals increasingly request photos documenting test procedures and results.

What happens:

Contractor completes thorough inspection, documents all test results in written report. Fire marshal asks for photos showing testing equipment used, device conditions, or deficiencies found. No photos available.

Inspector questions whether testing actually occurred as reported without visual evidence.

Why it happens:

NFPA 72 doesn’t explicitly require photographic documentation—but inspectors find photos helpful verifying work completed. Many contractors don’t realize photos are becoming expected documentation.

The fix:

Take photos during testing showing:

- Smoke detector testing (smoke source or magnet application)

- Heat detector testing (heat gun application)

- Pull station testing (device in activated position)

- Panel display during testing

- Any deficiencies or damage found

- Equipment or conditions before/after repairs

Modern smartphones make photography easy. Include date/time stamps on photos and reference device addresses in image descriptions.

—

Device Testing Procedure Mistakes

Testing procedures seem straightforward—but subtle errors invalidate results.

Wrong test methods for detector types

Different smoke detectors require specific testing approaches matching their detection technology.

Ionization smoke detectors:

Respond to small combustion particles. Should be tested with aerosol producing appropriate particle size or using manufacturer-provided magnet test.

Photoelectric smoke detectors:

Respond to larger smoke particles through light scattering. Require different aerosol or smoke source producing visible particles.

What goes wrong:

Technician uses same test aerosol for all smoke detectors regardless of type. Some detectors may not respond properly because test method doesn’t match detection principle.

Or technician uses magnet test on photoelectric detectors. Magnets only work with ionization detectors—photoelectric detectors won’t respond.

The result:

Detectors appearing to fail testing may actually be functional—just tested incorrectly. Or detectors passing inappropriate tests might not work properly during actual fires.

The fix:

Identify detector types before testing (check manufacturer markings or system documentation). Use appropriate test method:

- Ionization detectors: Aerosol designed for ionization or manufacturer magnet

- Photoelectric detectors: Visible smoke or aerosol for photoelectric sensors

- Multi-criteria detectors: Test both smoke sensing and heat sensing functions

- Aspirating detectors: Introduce test aerosol at farthest sampling port

NFPA 72 Section 14.4.5.3 allows manufacturer instructions to supersede general testing guidance. Always follow device-specific testing procedures when provided.

Insufficient test aerosol application

Smoke detectors must receive adequate test agent to activate reliably.

What goes wrong:

Technician briefly sprays aerosol near detector. Detector doesn’t activate within 5-10 seconds. Technician assumes detector is defective and schedules replacement.

Problem: Test aerosol application was insufficient. Quick spray doesn’t provide enough agent reaching sensing chamber to trigger alarm.

The result:

Functional detectors get replaced unnecessarily. Or technician eventually gets detector to activate after multiple attempts but records show long activation time suggesting detector problem when it’s actually testing technique issue.

The fix:

Apply test aerosol according to manufacturer instructions:

- Hold aerosol 6-12 inches from detector

- Apply 2-3 second burst directed at detector

- Wait 10-30 seconds for detector response (addressable detectors may respond faster)

- If no response after 30 seconds, apply second burst

- High-ceiling detectors may require longer application time due to distance

For ionization detectors using magnet test: Hold magnet in specified location for full time indicated in manufacturer instructions (typically 10-15 seconds).

Incomplete heat detector testing

Heat detectors often get tested incorrectly or skipped entirely.

What goes wrong:

Technician tests smoke detectors thoroughly but assumes heat detectors don’t require testing because they rarely fail. Or applies heat source briefly without verifying detector actually activates alarm.

The result:

Defective heat detectors remain in service undetected. During actual fires, these detectors fail to activate when needed.

The fix:

NFPA 72 Section 14.4.5.4 requires heat detector testing annually. Acceptable methods:

Heat gun method:

- Apply heat source per manufacturer instructions

- Maintain heat application until detector activates

- Fixed-temperature detectors must activate within rated range ±3%

- Rate-of-rise detectors must respond to 15°F per minute increase

Removal for bench testing:

- Remove detector from base

- Test in controlled environment

- Verify activation at correct temperature

- Reinstall and verify operation

Heat detector testing takes longer than smoke detector testing. Budget adequate time—don’t skip heat detectors because schedule is tight.

Improper manual pull station testing

Pull stations require complete activation cycle testing, not just visual inspection.

What goes wrong:

Technician verifies pull station glass or lever intact, assumes device functional without actually pulling it. Or pulls station but doesn’t verify alarm signal transmits properly through entire system.

The result:

Stuck mechanisms, broken wiring, or programming issues remain undetected. Pull station appears functional but won’t work during emergency.

The fix:

NFPA 72 Section 14.4.6.2 requires operating each pull station at least annually:

1. Pull station handle or break glass element

2. Verify alarm activates at control panel

3. Confirm notification devices activate throughout building

4. Check that monitoring station receives signal

5. Reset system properly

6. Restore pull station to normal condition (replace glass if broken, reset handle)

Document which specific pull station tested (address or location) and verify complete alarm sequence occurred—not just that device physically operates.

Skipping notification device testing

Testing focuses on detection devices while notification appliances get minimal attention.

What goes wrong:

Technician activates fire alarm verifying system sounds throughout building. Assumes all notification devices working because alarm is audible.

Problem: Individual devices may be malfunctioning while others compensate. Strobe synchronization issues may go unnoticed. Speaker voice intelligibility problems aren’t detected.

The result:

Code-required notification coverage may be inadequate. Occupants in some areas might not receive proper alarm notification during actual fires.

The fix:

Test notification appliances per NFPA 72 Section 14.4.3.2:

Audible devices (horns/bells/speakers):

- Activate each device or circuit

- Measure sound pressure levels at required locations

- Verify minimum 75 dBA in sleeping areas

- Confirm 15 dBA above ambient in other areas

- Document measurements on floor plan

Visual devices (strobes):

- Verify all strobes flash during alarm

- Check synchronization (all strobes in same area flash together)

- Confirm no strobes have failed or dimmed

- Measure candela output if required by AHJ

Voice systems:

- Test speakers in each zone

- Verify voice message clarity and intelligibility

- Check emergency microphone function

- Confirm backup tone signals work if voice fails

Don’t assume notification system works because you hear something. Verify every device functions properly and meets code requirements.

—

Timing and Frequency Mistakes

Testing must occur within specific timeframes—but scheduling errors are common.

Annual inspection performed late

NFPA 72 requires annual comprehensive testing within 365-day intervals.

What goes wrong:

Last annual inspection completed March 15, 2024. Building schedules next inspection for April 1, 2025—382 days later, exceeding annual requirement by 17 days.

Fire marshal inspects building March 25, 2025. Annual inspection is overdue. Violation issued regardless of whether testing gets completed week later.

Why it happens:

“Annual” seems like calendar year requirement. Property managers schedule testing in same month each year without tracking exact dates. Or contractor scheduling conflicts push inspection past anniversary date.

The fix:

Track exact inspection dates, not just months. Schedule next annual inspection 2-3 weeks before anniversary date providing buffer for:

- Contractor scheduling flexibility

- Weather delays

- Equipment problems found requiring correction

- Inspector schedule conflicts

Set calendar reminder 60 days before inspection due date ensuring adequate scheduling time. Document inspection completion date clearly for tracking next year’s deadline.

Monthly inspections skipped or inconsistent

NFPA 72 Table 14.3.1 requires monthly visual inspections of fire alarm equipment.

What goes wrong:

Building completes monthly inspections January through June. July and August skipped due to vacations. September inspection completed, then October skipped. November and December completed.

Fire marshal reviews documentation showing gaps. Writes violation for inadequate inspection frequency even though most months covered.

Why it happens:

Monthly inspections assigned to building maintenance staff. When staff member on vacation, nobody covers inspection. Or inspection happens but doesn’t get documented.

The fix:

Establish consistent schedule—first Tuesday of every month, for example. Assign backup person responsible when primary inspector unavailable.

Use calendar reminders ensuring inspections don’t get forgotten. Pre-print inspection checklists for entire year with dates already filled in.

If inspection must be skipped for legitimate reason (building closed, major construction preventing access), document reason for gap and resume regular schedule immediately.

Semi-annual testing not completed

NFPA 72 requires certain components tested semi-annually (every 6 months).

What goes wrong:

Building assumes annual comprehensive inspection satisfies all testing requirements. Semi-annual battery testing and notification appliance checks don’t occur separately.

Fire marshal asks for semi-annual test documentation. Records only show annual testing. Violation issued for missing semi-annual inspections.

Why it happens:

Property managers unfamiliar with different testing frequencies for various components. “Annual inspection” seems comprehensive covering everything.

The fix:

Understand NFPA 72 Table 14.3.1 specifies different frequencies:

Monthly: Visual inspections

Semi-annual: Batteries, notification appliances

Annual: Complete system including all devices

Schedule semi-annual testing approximately 6 months after annual inspection. Can be performed during regular quarterly maintenance visits if contractor provides this service.

Document semi-annual testing separately from annual comprehensive inspection showing compliance with all frequency requirements.

Sensitivity testing on wrong schedule

Smoke detectors require sensitivity testing after installation and when reaching specific ages.

What goes wrong:

Building tests smoke detectors annually using activation testing. Assumes this satisfies all requirements.

Fire marshal asks about sensitivity testing for detectors over 10 years old. Building has no sensitivity measurements because nobody tracked detector ages or performed required sensitivity testing.

Why it happens:

Detector age tracking requires records from original installation or device manufacturing dates. Many buildings don’t maintain this information.

The fix:

NFPA 72 Section 14.4.5.3.5 requires sensitivity testing:

- After detector installation (within 1 year)

- When detector reaches 10 years from manufacture date

- At intervals not exceeding 2 years after 10-year point

Create device age tracking spreadsheet:

- List all detectors by address or location

- Record manufacturing date (usually printed on detector)

- Calculate when 10-year sensitivity testing required

- Schedule testing before deadline

Many addressable systems track device installation dates automatically. Generate reports identifying detectors approaching age thresholds requiring sensitivity testing.

For conventional systems without automatic tracking, physically inspect devices recording manufacturing dates, then create manual tracking schedule.

—

Equipment and Tool Problems

Proper testing requires appropriate equipment—but contractors often use inadequate tools.

Uncalibrated testing equipment

Test instruments need regular calibration maintaining accuracy.

What goes wrong:

Fire marshal observes technician using decibel meter measuring notification device sound levels. Inspector asks when meter was last calibrated. Technician doesn’t know—meter purchased three years ago, never sent for calibration.

Inspector questions test result accuracy. May require re-testing using calibrated equipment.

Why it happens:

Calibration costs $75-200 per instrument and requires sending equipment to lab for 1-2 weeks. Contractors postpone calibration to avoid costs and inconvenience.

The fix:

NFPA 72 Section 14.2.3 requires test instruments maintained per manufacturer recommendations. Most testing equipment requires annual calibration.

Establish calibration schedule:

- Decibel meters: Annually

- Smoke detector test equipment: Per manufacturer (typically annually)

- Heat guns for detector testing: Annually

- Voltage meters: Annually

Keep calibration certificates with testing equipment. Include certificate copies with inspection reports proving instruments were properly calibrated during testing.

Budget calibration costs into annual maintenance expenses. Equipment producing inaccurate readings creates liability if defects go undetected.

Wrong aerosol for smoke detector type

Test aerosols designed for specific detector technologies.

What goes wrong:

Technician uses general-purpose test aerosol purchased at hardware store. Some smoke detectors respond erratically or don’t respond at all because aerosol particle size doesn’t match detector sensitivity.

Why it happens:

Proper smoke detector test aerosols cost $15-30 per can from fire protection suppliers. Generic “detector test spray” from hardware stores costs $8-12. Contractors choose cheaper option not realizing effectiveness difference.

The fix:

Use manufacturer-approved test aerosols:

- SDi SmokeSabre (photoelectric detectors)

- Solo A3 or Trutest aerosol (ionization detectors)

- Manufacturer-specific aerosols for specialized detectors

Generic aerosols may work on some detectors but produce unreliable results across all detector types. Professional-grade test agents ensure consistent, code-compliant testing.

Inadequate access equipment

High ceilings require proper ladders or lifts reaching detectors safely.

What goes wrong:

Building has 14-foot ceilings. Technician brings 12-foot ladder. Can’t safely reach detectors for close inspection or maintenance. Tests devices from ground level using long pole with test aerosol—inadequate for proper testing.

Why it happens:

Tall ladders or scissor lifts expensive and difficult to transport. Contractors attempt testing with inadequate equipment rather than renting proper access.

The fix:

Inspect building before testing identifying ceiling heights and access challenges. Bring appropriate equipment:

- Ceilings 10-12 feet: 8-10 foot ladder adequate

- Ceilings 12-15 feet: 12-14 foot ladder required

- Ceilings over 15 feet: Scissor lift or aerial work platform necessary

OSHA fall protection requirements apply. Technicians working over 6 feet height need proper fall protection or appropriate access equipment (stable ladders, work platforms).

Budget rental costs for specialized access equipment into testing quotes. Inadequate access creates safety risks and produces incomplete testing.

Missing documentation forms

Pre-printed checklists ensure consistent documentation.

What goes wrong:

Technician arrives at building with blank notebook. Tests devices recording results in rough notes intending to type formal report later. Gets busy with other jobs, formal report never completed. Documentation remains illegible handwritten notes.

Why it happens:

Creating documentation templates takes time. Contractors operate reactively handling urgent calls rather than preparing organized documentation systems.

The fix:

Develop standardized testing forms including:

Device testing checklist:

- Pre-printed spaces for device addresses/locations

- Columns for test date, method, results, technician initials

- Section for sound pressure measurements with floor plan

- Battery testing results table

- Deficiency list with repair documentation

Panel testing form:

- Power failure test results

- Ground fault test results

- Alarm signal transmission verification

- Trouble signal testing

- System reset verification

Completion certificate:

- Building information

- Test date and scope

- Certification statement

- Technician signature and license number

- Engineer stamp (if required)

Print forms before arriving at testing locations. Complete during testing rather than reconstructing from memory later.

Many fire alarm manufacturers provide free testing forms downloadable from websites. Customize these templates for specific building needs.

—

System-Specific Testing Challenges

Different fire alarm architectures create unique testing complications.

Conventional system zone confusion

Conventional panels indicate zones rather than individual devices.

What goes wrong:

Panel shows “Zone 2 Alarm.” Technician activates detector in Zone 2 verifying alarm. Fire marshal asks which specific detector tested. Technician doesn’t remember—zone has 15 detectors, any could have activated.

Documentation lists “Zone 2 tested, passed” without device-specific information. Inspector requires knowing every device tested individually.

Why it happens:

Conventional systems don’t identify individual devices. Testing any device in zone confirms zone circuit works—but doesn’t verify every device functional.

The fix:

Test every device in zone individually even though panel only shows zone response:

1. Activate first device in zone

2. Verify zone alarm on panel

3. Reset system

4. Document device location tested

5. Repeat for each device in zone

Requires as-built drawings showing device locations within zones. Cross-reference physical device locations to zone numbers creating device list for documentation.

Time-consuming but necessary proving comprehensive testing occurred—not just sampling.

Addressable system programming errors

Addressable systems require correct programming matching physical devices.

What goes wrong:

Fire marshal asks to see Device 142 (Second Floor Conference Room). Property manager uses panel display showing Device 142 is second floor conference room smoke detector. Inspector checks conference room finding Device 142 is actually in adjacent corridor—label is wrong.

Programming doesn’t match physical reality. Inspector questions entire system accuracy.

Why it happens:

Device programming occurs during installation. Building renovations relocate devices or change room names. System programming never updates matching new building layout.

The fix:

Verify addressable device programming matches physical locations:

During annual inspections:

- Technician activates each device

- Panel display shows programmed location

- Technician confirms device is actually at stated location

- Updates programming if discrepancies found

Update system programming immediately when:

- Devices relocated during renovations

- Room names or numbers change

- New construction adds areas

- Devices replaced with different addresses

Provide building management with updated device location list after programming changes. As-built drawings should reflect current device addresses and locations—not original construction.

Wireless system battery failures

Wireless devices require functioning batteries for operation.

What goes wrong:

Technician tests wireless smoke detector with test aerosol. Detector activates properly. Three months later, detector battery dies. Device stops communicating with panel creating trouble condition nobody notices for weeks.

Fire marshal inspection finds devices with dead batteries. Violation issued because devices aren’t operational even though passed testing months earlier.

Why it happens:

Wireless device batteries typically last 5-10 years. Near end of life, batteries can work during testing but fail soon after. Panel supervision detects communication loss but trouble signals sometimes get ignored.

The fix:

NFPA 72 Section 14.4.6.3 requires wireless device testing includes:

- Device activation testing

- Battery voltage measurement

- Signal strength verification

- Communication supervision check

Test battery voltage even if device operates. Replace batteries showing voltage below manufacturer minimum threshold (typically 3.0-3.6 volts depending on battery type).

Track battery replacement dates. Schedule proactive replacement at 80% of rated battery life rather than waiting for failures:

- 10-year rated batteries: Replace at 8 years

- 5-year rated batteries: Replace at 4 years

Address panel trouble conditions immediately. Low battery troubles indicate devices need replacement before complete failure occurs.

Voice evacuation system intelligibility issues

Voice systems require clear, understandable messages.

What goes wrong:

Technician activates voice evacuation system. Speakers throughout building produce audio. Technician assumes voice system works properly.

Fire marshal stands in far corner of building during testing. Speaker volume barely audible or message garbled and unintelligible. Violation issued for inadequate voice notification.

Why it happens:

Sound carries differently in various spaces. Location near speakers sounds clear while distant locations receive poor audio quality. Single-point testing doesn’t identify coverage gaps.

The fix:

NFPA 72 Chapter 24 requires voice systems meet intelligibility standards:

- Speech Transmission Index (STI) of 0.5 minimum

- Common Intelligibility Scale (CIS) score of 0.7 minimum

Test voice system intelligibility at multiple locations:

- Farthest point from speakers in each area

- Locations with high ambient noise (near HVAC, machinery)

- Acoustically difficult spaces (large open areas, reflective surfaces)

- All levels in multi-story buildings

Use speech intelligibility meter measuring STI values, or conduct subjective listening tests where person unfamiliar with message attempts comprehension from various locations.

Document intelligibility at tested locations. If any areas fail to meet standards, adjust speaker volumes, add speakers, or modify messaging improving clarity.

Need help avoiding these common fire alarm testing mistakes? [Talk to an expert](/contact-us) at 48fire who can perform code-compliant testing, provide proper documentation, and ensure your system passes inspections the first time.

—

What These Patterns Reveal

Thousands of fire alarm testing errors share common themes revealing underlying problems.

Knowledge gaps create repeated mistakes

Same errors appear across different buildings and contractors because testing procedures aren’t intuitive.

The pattern:

- Technicians understand devices should activate during testing

- Don’t always know specific test methods required for each device type

- Assume passing basic functional tests satisfies all code requirements

- Miss nuanced requirements buried in NFPA 72 technical sections

Why this matters:

Fire protection is specialty trade requiring specific training. General electrical or HVAC contractors sometimes perform fire alarm testing without adequate fire protection knowledge. Results in testing that seems thorough but misses code requirements.

The solution:

Use contractors with specific fire alarm qualifications:

- NICET certification in Fire Alarm Systems (Level II minimum)

- State fire alarm contractor license where required

- Manufacturer-specific training for installed equipment

- Regular continuing education on NFPA 72 updates

Ask contractors about qualifications before hiring. Lowest-cost provider often lacks specialized knowledge necessary for code-compliant testing.

Documentation standards vary widely

Some contractors provide comprehensive documentation while others offer minimal reports.

The pattern:

- Quality documentation includes device lists, measurements, photos, certifications

- Minimal documentation states “tested and passed” with little supporting detail

- Fire marshals increasingly request comprehensive documentation

- Buildings with minimal documentation face repeated inspection problems

Why this matters:

Documentation proves testing occurred properly. Without detailed records, inspectors can’t verify code compliance even if testing was actually thorough.

The solution:

Establish documentation requirements before contractors perform testing:

- Device-by-device test results (not just summaries)

- Sound pressure measurements with floor plan

- Battery voltage readings

- Sensitivity test results where required

- Photographic documentation

- Professional engineer certification

Include documentation requirements in service contracts. Specify deliverable format (printed report, electronic PDF, spreadsheet data).

Review sample reports from contractors before hiring. Comprehensive documentation correlates with thorough testing—contractors producing detailed reports typically perform better testing.

Timing pressure leads to shortcuts

Annual inspections performed under time constraints produce incomplete testing.

The pattern:

- Contractors bid testing at competitive prices requiring efficient work

- Comprehensive testing takes longer than scheduled

- Technicians skip steps saving time

- Testing appears complete but misses requirements

Why this matters:

Proper fire alarm testing cannot be rushed. System with 300+ devices requires 6-10 hours for complete NFPA 72 compliant inspection including:

- Testing every detection device

- Measuring notification device sound levels

- Checking all interfaces

- Documenting results thoroughly

Contractors bidding 4-hour inspections on 300-device systems will inevitably cut corners.

The solution:

Understand realistic testing timeframes:

- Small system (under 50 devices): 2-4 hours

- Medium system (50-150 devices): 4-8 hours

- Large system (150+ devices): 8-16 hours

Extremely complex systems may require multiple days for complete testing.

Get detailed scope descriptions from contractors. Lowest bid often represents incomplete testing scope. Compare quotes carefully ensuring all contractors including same testing elements.

Equipment limitations affect results

Testing quality depends on having proper tools.

The pattern:

- Professional testing equipment expensive ($2,000-5,000 complete kit)

- Smaller contractors use inadequate tools keeping costs down

- Inaccurate measurements or incomplete testing results

- Problems discovered only during fire marshal inspections using proper equipment

Why this matters:

Can’t verify code compliance without proper measuring instruments. Sound levels, sensitivity readings, voltage measurements must be accurate—not estimated.

The solution:

Ask contractors about testing equipment before hiring:

- Calibrated decibel meter for sound measurements

- Smoke detector sensitivity testing equipment

- Heat sources for detector testing

- Battery load testing equipment

- Voltage meters for electrical measurements

Request calibration certificates proving instruments accurate. Well-equipped contractors indicate investment in quality testing capabilities.

Follow-up procedures often neglected

Testing identifies problems—but repairs sometimes get deferred.

The pattern:

- Annual inspection finds 12 deficiencies requiring correction

- Contractor provides report listing problems

- Building manager intends to schedule repairs

- Repairs never completed

- Next fire marshal inspection cites same deficiencies

- Property surprised problems still exist after “passing” contractor inspection

Why this matters:

Finding problems during testing doesn’t satisfy code requirements—fixing problems does. Documented deficiencies remaining uncorrected are automatic violations during official inspections.

The solution:

Treat contractor testing as preliminary inspection before official fire marshal visit:

1. Schedule contractor testing 60-90 days before fire marshal inspection

2. Review contractor report immediately identifying all deficiencies

3. Schedule deficiency corrections within two weeks

4. Verify repairs completed before fire marshal inspection

5. Update documentation showing corrections made

Annual inspection should identify problems early enough allowing time for proper repairs before official inspections occur.

—

Practical Prevention Strategies

Understanding common errors enables preventing them systematically.

Create testing checklist library

Standardized checklists ensure consistent comprehensive testing.

What to include:

Monthly visual inspection checklist:

- Panel status indicators check

- Visible device condition review

- Access and clearance verification

- Trouble condition documentation

Semi-annual testing checklist:

- Battery voltage measurements

- Load testing procedure

- Notification device activation

- Interface function verification

Annual comprehensive inspection checklist:

- Every device testing procedure

- Sound pressure measurement locations

- Sensitivity testing requirements

- Documentation completion requirements

Special testing checklist:

- Duct detector testing steps

- Aspirating system testing procedure

- Voice system intelligibility testing

- Wireless device signal strength verification

Customize checklists for specific building and system type. Include space for dates, signatures, results, and notes.

Store checklists with fire alarm documentation. Provide copies to contractors performing testing ensuring they understand required scope.

Establish contractor qualification criteria

Not all fire protection contractors provide equal service quality.

Minimum qualifications:

- State fire alarm contractor license (where required)

- NICET certification Level II or higher

- Professional liability insurance

- UL or manufacturer certifications for installed equipment types

- Minimum 5 years fire alarm testing experience

Evaluation questions:

“What testing equipment do you use and when was it last calibrated?”

“Can you provide sample inspection reports from similar buildings?”

“How many technicians will perform the testing and what are their qualifications?”

“What documentation will you provide after testing?”

“How long do you estimate testing will take for our building?”

“What’s your process if deficiencies are found during testing?”

Request references from buildings similar size and system type. Contact references asking about documentation quality, thoroughness, and problem resolution.

Price shouldn’t be only selection factor. Comprehensive testing from qualified contractor costs more but prevents inspection failures and provides confidence in system reliability.

Build buffer time into scheduling

Testing rushed to meet tight deadlines produces errors.

Recommended timeline:

90 days before fire marshal inspection: Schedule contractor annual testing

60 days before inspection: Complete contractor testing

45 days before inspection: Review contractor report and identify deficiencies

30 days before inspection: Complete all required repairs

14 days before inspection: Verify all corrections made and documentation updated

7 days before inspection: Pre-inspection walkthrough ensuring everything ready

This timeline provides adequate buffer for unexpected problems:

- Contractor scheduling delays

- Equipment delivery delays for repairs

- Complex deficiencies requiring engineering review

- Weather preventing testing (if outdoor components involved)

Scheduling contractor testing week before fire marshal inspection creates crisis if problems found. Allow time to fix issues properly rather than scrambling for emergency corrections.

Implement documentation review procedures

Review contractor reports thoroughly before accepting completion.

Review checklist:

- Device list includes every detector, pull station, and notification device with test results

- Sound pressure measurements documented with floor plan showing measurement locations

- Sensitivity testing completed for all detectors over 10 years old with readings recorded

- Battery test results include voltage measurements under load

- Interface testing documented for HVAC, elevators, doors

- Photographs included showing testing procedures and any deficiencies

- Technician signatures and certifications present

- Professional engineer stamp if required by jurisdiction

- Deficiency list clearly identifies problems found

- Recommendations provided for corrections

If report lacks required elements, request complete documentation before making final payment. Incomplete reports create problems during fire marshal inspections.

Maintain continuous compliance mentality

Code compliance requires year-round attention, not just before inspections.

Monthly:

- Visual inspections by building staff

- Alarm test verifying system operation

- Trouble condition response and resolution

- Documentation filing

Quarterly:

- Contractor preventive maintenance visits

- Device cleaning in high-contamination areas

- Battery testing and replacement as needed

- System health review

Semi-annually:

- Comprehensive battery testing

- Notification device testing

- Interface function verification

Annually:

- Complete NFPA 72 comprehensive inspection

- Sensitivity testing for older detectors

- Sound pressure measurements

- Full documentation review and update

Buildings maintaining this schedule rarely encounter inspection surprises. Continuous compliance approach finds and fixes problems before official inspections occur.

Treating fire alarm testing as annual event inevitably produces last-minute problems. Treating it as ongoing operational requirement prevents testing errors and ensures reliable fire protection.

—

Conclusion

Analysis of fire alarm testing across thousands of commercial buildings reveals consistent error patterns—most of which are preventable.

Common testing mistakes:

Documentation problems account for 42% of testing issues. Missing test dates, incomplete sensitivity records, absent sound pressure measurements, and inadequate photos create violations even when physical testing was thorough.

Device testing procedure mistakes represent 31% of errors. Wrong test methods for detector types, insufficient aerosol application, incomplete heat detector testing, and skipped notification device verification produce unreliable results.

Timing and frequency errors cause 18% of problems. Late annual inspections, skipped monthly checks, missing semi-annual testing, and wrong sensitivity testing schedules create automatic code violations.

Equipment and tool problems create 9% of testing issues. Uncalibrated instruments, wrong test aerosols, inadequate access equipment, and missing documentation forms limit testing effectiveness.

What prevents these mistakes:

Qualified contractors with proper training, certifications, and experience reduce testing errors significantly. Comprehensive documentation standards ensure code compliance can be verified. Adequate testing timeframes allow thorough work rather than rushed shortcuts. Proper equipment enables accurate measurements and reliable testing.

The systematic approach:

Successful fire alarm testing requires planning and consistency:

- Schedule testing 60-90 days before fire marshal inspections

- Use qualified contractors with proven documentation quality

- Review test reports thoroughly before accepting completion

- Address deficiencies immediately with adequate correction time

- Maintain continuous compliance through monthly, quarterly, and semi-annual activities

Prevention investment:

Proper testing costs more than minimal approaches—but prevents expensive problems:

- Code violations requiring emergency corrections

- Failed inspections necessitating re-testing and re-inspection fees

- Undetected equipment failures compromising fire protection

- False confidence in systems that won’t function properly during fires

Buildings investing in thorough code-compliant testing avoid these costs while ensuring reliable fire protection.

The practical reality:

Fire alarm testing mistakes are common because requirements are detailed and procedures are technical. But understanding typical errors enables preventing them through better contractor selection, adequate scheduling, comprehensive documentation, and consistent compliance practices.

The goal isn’t perfect testing—it’s reliable fire protection. Proper testing procedures verify systems will protect building occupants when needed. That’s what matters most.