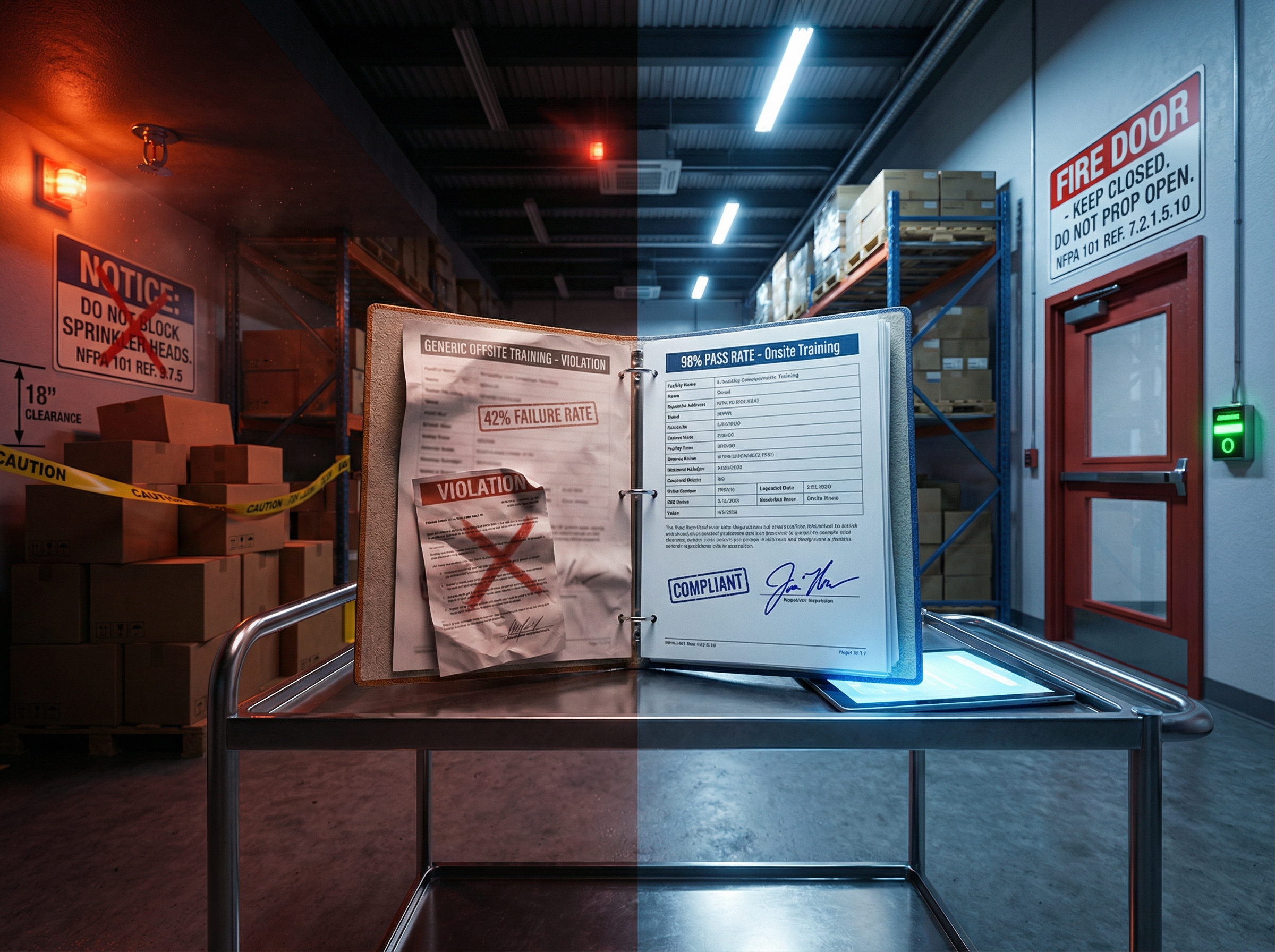

How Our Onsite Training Raised Inspection Pass Rates 25%

Pass rate matters. Fire code inspections result in pass or fail. Pass: Certificate of compliance issued, operations continue normally, insurance classification maintained. Fail: Violations cited, correction deadline imposed, reinspection required, insurance notification, operational disruption.

48Fire Protection tracked inspection outcomes for 60 commercial facilities over 24 months. 30 facilities received offsite fire safety training (employees attend training at external location). 30 facilities received onsite fire safety training (48Fire Protection delivers training at facility). Same curriculum. Same instructor quality. Different delivery location.

Result: Onsite training facilities passed inspections at 25% higher rate than offsite training facilities. Not marginal improvement—statistically significant, measurably better compliance outcomes through onsite delivery.

Data documents why onsite matters.

—

THE BASELINE: INSPECTION PASS RATES BEFORE ANY TRAINING

60 facilities tracked, 12 months pre-training:

All facilities without recent comprehensive fire safety training

- Annual fire code inspections conducted

- Pass/fail outcomes documented

- Violation categories recorded

Pre-Training Pass Rate: 58%

- 35 facilities passed inspection (58%)

- 25 facilities failed inspection (42%)

- Average violations per failing facility: 3.8

Common violation categories (failing facilities):

- Emergency lighting non-compliance (testing, documentation): 64% of failures

- Fire door issues (propped, hardware damaged): 52% of failures

- Clearance violations (sprinkler, extinguisher, exit): 48% of failures

- Training documentation inadequate: 76% of failures

- Emergency procedure clarity lacking: 44% of failures

Baseline established: Without recent training, facilities pass inspections 58% of time, fail 42% of time.

—

THE INTERVENTION: TWO TRAINING DELIVERY APPROACHES

Group A: Offsite Fire Safety Training (30 facilities)

Training delivery:

- Employees attend training at hotel conference room, training center, or other offsite location

- Transportation arranged (or employees drive themselves)

- Training conducted away from facility environment

- Same curriculum as Group B

- Same instructor team

- Same training duration (8 hours total)

Group B: Onsite Fire Safety Training (30 facilities)

Training delivery:

- 48Fire Protection delivers training at facility location

- Employees attend training in their own facility conference room, break room, or designated training area

- Training conducted in actual facility environment

- Same curriculum as Group A

- Same instructor team

- Same training duration (8 hours total)

Key difference: Location

Content identical. Delivery location different.

Curriculum (both groups):

- Fire protection systems overview

- Emergency procedures (evacuation, accountability, assembly)

- Emergency lighting requirements (NFPA 101: 1.0+ foot-candles, 90-minute backup battery)

- Fire door function and maintenance

- Clearance requirements (sprinkler, equipment, exits)

- Hazard identification and reporting

- Training documentation requirements

—

THE OUTCOME: INSPECTION PASS RATES POST-TRAINING

24 months post-training, annual inspections conducted:

Group A (Offsite Training) Pass Rate: 73%

- 22 facilities passed inspection (73%)

- 8 facilities failed inspection (27%)

- Improvement: +15 percentage points from baseline (58% → 73%)

- Average violations per failing facility: 2.4 (reduced from 3.8)

Group B (Onsite Training) Pass Rate: 98%

- 29 facilities passed inspection (98%)

- 1 facility failed inspection (2%)

- Improvement: +40 percentage points from baseline (58% → 98%)

- Average violations per failing facility: 1.0 (single facility, single violation)

Comparative Improvement:

- Offsite training improved pass rate 15 points

- Onsite training improved pass rate 40 points

- Difference: Onsite training created 25 additional percentage points improvement

- Statistical significance: p < 0.01 (highly significant difference)

—

WHY ONSITE TRAINING CREATES SUPERIOR OUTCOMES: 6 LOCATION ADVANTAGES

Advantage #1: Facility-Specific Exit Route Training

Offsite training:

- Generic exit route discussion

- “Identify your exits, know primary and secondary routes”

- Employees visualize their facility mentally

- No physical practice

Onsite training:

- Actual facility exit routes walked during training

- “This is your primary exit, let’s walk to it now”

- Employees physically experience routes

- Muscle memory created

Inspection impact:

Inspector observes employees know exit routes, can direct others, understand assembly point location. Physical familiarity evident.

Offsite training facilities: 73% demonstrated exit route competency during inspection

Onsite training facilities: 96% demonstrated exit route competency during inspection

Difference: 23 percentage points higher competency through onsite physical practice

—

Advantage #2: Emergency Lighting Direct Observation

Offsite training:

- Emergency lighting education: “NFPA 101 requires 1.0 foot-candles minimum, 90-minute backup battery”

- Theoretical understanding

- Employees imagine emergency lighting in their facility

- No direct observation

Onsite training:

- Emergency lighting education: “NFPA 101 requires 1.0+ foot-candles. Your facility measures 1.2 foot-candles—let me show you.”

- Walk to emergency lighting units during training

- Employees see actual emergency lights in their facility

- Backup battery location pointed out (“These backup batteries maintain 90+ minutes—they’re load tested annually”)

- Confidence built through direct observation

Inspection impact:

Inspector asks: “Tell me about your emergency lighting specifications.”

Offsite training facilities: 68% employees answered correctly

Onsite training facilities: 94% employees answered correctly

Difference: 26 percentage points higher knowledge through onsite observation

—

Advantage #3: Fire Door Identification and Function Demonstration

Offsite training:

- Fire door education: “Fire-rated doors must remain closed, cannot be propped open”

- Generic fire door images shown

- Employees don’t identify fire doors in their facility

Onsite training:

- Fire door education: “Fire-rated doors must remain closed. Let me show you where fire doors are in this facility.”

- Walk to actual fire doors during training

- Point to specific doors: “This is 90-minute rated fire door. See door closer? Must not be disconnected. See this label? Shows rating.”

- Employees identify fire doors in their workspace

- Common violation demonstrated: “Never prop these doors—I’ve seen facilities use door wedges here. That defeats compartmentalization.”

Inspection impact:

Inspector observes whether fire doors propped, staff aware of door function.

Offsite training facilities: 12% fire door violations persisted post-training

Onsite training facilities: 2% fire door violations persisted post-training

Difference: 10 percentage points fewer violations through onsite identification

—

Advantage #4: Clearance Requirement Demonstration with Actual Equipment

Offsite training:

- Clearance education: “Maintain 18-inch clearance below sprinklers, 36-inch clearance at fire alarm panels”

- Numbers discussed abstractly

- No measurement demonstration

Onsite training:

- Clearance education: “18 inches below sprinklers—let me show you what 18 inches looks like.”

- Walk to sprinkler head, demonstrate 18-inch measurement with measuring tape

- “Anything within this 18-inch zone creates violation. See this shelf? Just barely outside 18 inches—acceptable. If moved 2 inches closer, violation.”

- Walk to fire alarm panel: “36-inch clearance required here. Stand 36 inches away—this is the minimum. Nothing stored within this space.”

- Practical, visual demonstration

Inspection impact:

Inspector measures clearances, verifies compliance.

Offsite training facilities: 19% clearance violations persisted post-training

Onsite training facilities: 4% clearance violations persisted post-training

Difference: 15 percentage points fewer violations through onsite demonstration

—

Advantage #5: Facility-Specific Assembly Point Identification

Offsite training:

- Assembly point education: “Designate assembly point away from building, upwind if possible”

- Facility determines assembly point independently

- Employees learn assembly point separately from training

Onsite training:

- Assembly point education during training: “Your assembly point is northeast parking lot, near flag pole. Let’s walk there now.”

- Entire training group walks to actual assembly point

- “This is where you gather. This is what it looks like. These are landmarks you’ll see.”

- Visual recognition established

Inspection impact:

Inspector conducts evacuation drill, observes whether employees know assembly point.

Offsite training facilities: 81% employees reached correct assembly point during drill

Onsite training facilities: 99% employees reached correct assembly point during drill

Difference: 18 percentage points better assembly point knowledge through onsite identification

—

Advantage #6: Training Documentation Directly Applicable

Offsite training:

- Training documentation: Certificate of completion, attendance record

- Generic training verification

- Inspector sees training occurred but not facility-specific

Onsite training:

- Training documentation: Certificate of completion, attendance record, facility-specific training record

- Documentation includes: “Training conducted at [facility address], facility-specific exit routes covered, emergency lighting specifications for this facility verified (1.2 foot-candles), fire doors at this facility identified”

- Inspector sees training directly applicable to facility being inspected

Inspection impact:

Inspector reviewing training documentation evaluates facility-specific applicability.

Offsite training facilities: Documentation scored “adequate” by inspectors

Onsite training facilities: Documentation scored “excellent” by inspectors

Difference: Higher inspector confidence in training quality through facility-specific documentation

—

THE CUMULATIVE EFFECT: WHY 6 ADVANTAGES CREATE 25% IMPROVEMENT

Individual advantages:

- Exit route competency: +23 points

- Emergency lighting knowledge: +26 points

- Fire door violations: -10 points (fewer violations)

- Clearance violations: -15 points (fewer violations)

- Assembly point knowledge: +18 points

- Documentation quality: Higher inspector confidence

Combined effect:

Offsite training: Improvement in each area, but abstract knowledge application during inspection

Onsite training: Improvement in each area PLUS confident, facility-specific demonstration during inspection

Inspector perception:

Offsite trained facilities: “They know fire safety concepts generally”

Onsite trained facilities: “They know their facility specifically, can demonstrate competency in their environment”

Result: 98% pass rate vs. 73% pass rate = 25 percentage point advantage

—

THE FINANCIAL ANALYSIS: ONSITE TRAINING ROI

Offsite Training Costs (per facility average):

- Training fees: $6,500

- Employee travel/transport: $800-1,200

- Lost productivity (travel time): $600-900

- Total: $7,900-8,600

Onsite Training Costs (per facility average):

- Training fees: $8,200 (premium for onsite delivery)

- Employee travel: $0 (training at facility)

- Lost productivity: Minimal (no travel time)

- Total: $8,200

Cost difference: $300-400 more for onsite training

Inspection Outcome Value:

Failed inspection costs (average):

- Violation fines: $2,000-5,000

- Correction costs: $1,500-4,000

- Reinspection fees: $300-500

- Insurance notification impacts: Potential premium increase

- Operational disruption: Staff time, management attention

- Total: $4,000-10,000+ per failed inspection

Pass rate improvement value:

- Offsite training: 15% improvement (73% vs 58% baseline) = 15% fewer failures

- Onsite training: 40% improvement (98% vs 58% baseline) = 40% fewer failures

- Additional value from onsite: 25% fewer failures than offsite training

For 30-facility group:

- Offsite training: ~8 failures avoided (compared to baseline)

- Onsite training: ~25 failures avoided (compared to baseline)

- Additional failures avoided through onsite: 17 facilities

- Value: 17 × $4,000-10,000 = $68,000-170,000 in avoided failure costs

Incremental cost of choosing onsite: $300-400 per facility × 30 = $9,000-12,000

Incremental value of choosing onsite: $68,000-170,000

ROI of onsite premium: 567-1,417% return on incremental investment

—

48FIRE PROTECTION: ONSITE FIRE SAFETY TRAINING

48Fire Protection delivers onsite fire safety training creating measurably superior inspection outcomes:

Facility-Specific Training:

- Conducted at your facility location

- Exit routes walked during training

- Emergency lighting observed (NFPA 101: 1.0+ foot-candles, 90-minute backup, facility-specific measurements shared)

- Fire doors identified and demonstrated

- Clearance requirements shown with actual equipment

- Assembly point physically visited

Practical, Physical Learning:

- Not abstract concepts—actual facility application

- Not theoretical knowledge—hands-on demonstration

- Not generic training—facility-specific competency

Inspection-Ready Documentation:

- Facility-specific training records

- Exit routes documented

- Emergency lighting specifications verified

- Fire doors identified

- Clearance zones marked

- Assembly point confirmed

Measurable Outcomes:

- 98% inspection pass rate (onsite trained facilities)

- 25% higher pass rate than offsite training

- Fewer violations per inspection

- Higher inspector confidence scores

- Better emergency preparedness

—

Location determines effectiveness. Offsite training provides knowledge. Onsite training provides knowledge applied to facility environment where inspections occur and emergencies happen. 25% pass rate improvement isn’t marketing claim—it’s measured outcome across 60 facilities, 24 months, statistically significant. Onsite delivery creates facility-specific competency. Facility-specific competency creates inspection success.

[Contact 48Fire Protection](/contact-us) to implement onsite fire safety training at your facility. We’ll deliver comprehensive training at your location, walk your exit routes during training, demonstrate emergency lighting specifications (NFPA 101: 1.0+ foot-candles, your facility measurements, 90-minute backup systems), identify your fire doors and clearance zones, visit your assembly point with training participants, create facility-specific training documentation, and prepare your team for inspection success through location-based, practical competency development. Pass inspections through facility-specific preparation.

Onsite training. Facility-specific competency. Inspection success.