How Routine Extinguisher Testing Supports Fire Safety Compliance

—

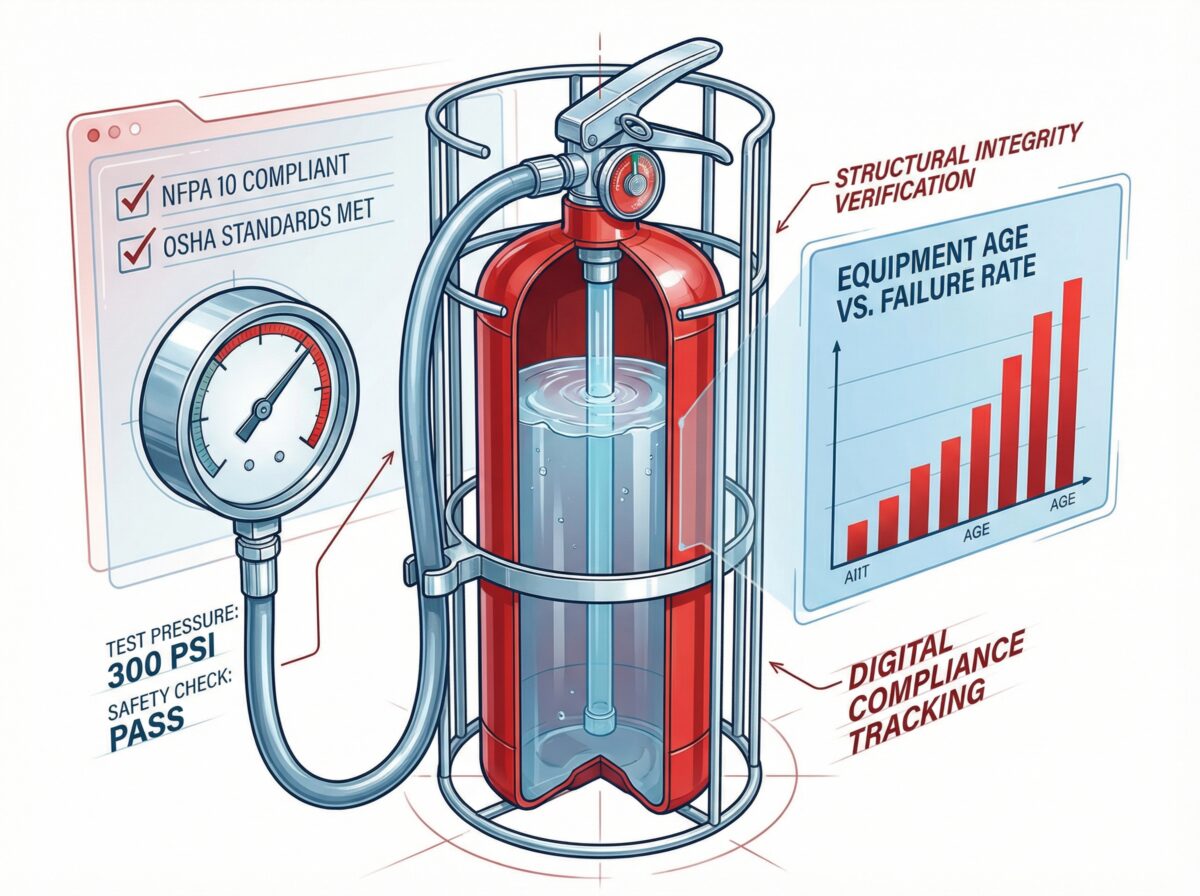

THE COMPLIANCE VERIFICATION FRAMEWORK

Fire safety inspection programs operate on fundamental principle:

What gets measured gets maintained. What gets tested gets trusted.

Facilities perform monthly visual inspections verifying extinguisher presence and apparent condition. These inspections answer question: “Does equipment look okay?”

Hydrostatic testing answers different question: “Is equipment structurally safe?”

Visual inspection cannot detect:

- Internal corrosion weakening vessel walls

- Stress fractures invisible externally

- Metal fatigue from age and pressure cycles

- Structural degradation compromising containment

Hydrostatic testing verifies pressure vessel integrity through actual pressure application—the only method definitively confirming equipment remains safe for continued pressurized service.

Fire safety inspection programs incorporating routine extinguisher testing achieve compliance verification impossible through visual examination alone.

This article examines how hydrostatic testing supports fire safety inspection compliance across regulatory, operational, and risk management dimensions.

—

REGULATORY COMPLIANCE DIMENSION

The Mandatory Testing Requirements

Fire safety inspection regulations require periodic hydrostatic testing as non-negotiable compliance element.

—

NFPA 10 Testing Mandates

NFPA 10 Section 8.1:

“Hydrostatic testing is a means to periodically determine that a fire extinguisher’s pressure vessel is safe for continued use.”

Purpose statement clarifies intent:

- Not optional maintenance recommendation

- Not suggested best practice

- Mandatory safety verification

NFPA 10 Section 8.3 establishes:

- Testing intervals per Table 8.3.1

- Testing procedures (Section 8.3.1)

- Equipment requirements (Section 8.3.2)

- Record-keeping mandates (Section 8.3.3)

- Failed equipment protocols (Section 8.3.5)

—

NFPA 10 Table 8.3.1 Test Intervals

Mandatory testing frequencies:

| Extinguisher Type | Test Interval | Compliance Requirement |

|---|---|---|

| Carbon Dioxide (CO2) | 5 years | First test 5 years after manufacturing, subsequent tests every 5 years |

| Water (stored pressure) | 5 years | First test 5 years after manufacturing, subsequent tests every 5 years |

| Foam (stored pressure) | 5 years | First test 5 years after manufacturing, subsequent tests every 5 years |

| Wet Chemical | 5 years | First test 5 years after manufacturing, subsequent tests every 5 years |

| Dry Chemical (stored pressure) | 12 years | First test 12 years after manufacturing, subsequent tests every 12 years |

| Clean Agent (Halotron, FE-36) | 12 years | First test 12 years after manufacturing, subsequent tests every 12 years |

Fire safety inspection compliance requires:

- Equipment age tracking

- Test due date calculation

- Testing completion before deadline

- Documentation maintenance

48Fire fire safety inspection services include automated testing schedule tracking ensuring compliance deadlines met.

—

OSHA Integration

OSHA 29 CFR 1910.157(g)(1):

“The employer shall assure that hydrostatic testing is performed by trained persons with suitable testing equipment and facilities.”

OSHA requirements specify:

- Testing must occur (not optional)

- Qualified personnel required

- Proper equipment necessary

- Suitable facilities essential

Compliance verification through fire safety inspection:

- Testing performed per NFPA intervals

- Service provider qualifications documented

- Testing facility credentials verified

- Proper procedures followed

Fire safety inspection programs incorporating 48Fire testing services satisfy OSHA 29 CFR 1910.157(g)(1) requirements through certified facilities and trained technicians.

—

Documentation Requirements

NFPA 10 Section 8.3.3:

“Permanent records shall be maintained for each hydrostatic test.”

Required documentation:

□ Date of test

□ Test pressure applied

□ Test duration

□ Pass/fail determination

□ Name of person performing test

□ Serial number or unique identifier

□ Next test due date

Fire safety inspection compliance depends on:

- Complete testing records

- Permanent record maintenance

- Accessible documentation

- Audit-ready organization

48Fire provides comprehensive testing documentation satisfying NFPA 10 Section 8.3.3 requirements with digital record-keeping ensuring permanent accessibility.

—

OPERATIONAL COMPLIANCE DIMENSION

The Safety Verification Process

Fire safety inspection programs verify equipment remains operationally safe through systematic testing protocols.

—

Testing Procedure Overview

NFPA 10 Section 8.3.1 hydrostatic testing procedure:

STEP 1: Pre-Test Preparation

□ Complete discharge of extinguisher

□ Valve assembly removal

□ Internal cleaning performed

□ Visual internal examination

□ Exterior cleaning completed

STEP 2: Test Setup

□ Extinguisher placed in testing apparatus

□ Safety cage or barrier utilized

□ Water fill (incompressible fluid)

□ Air completely evacuated

□ Pressure gauge installed

STEP 3: Pressure Application

□ Test pressure applied gradually

□ Test pressure: Typically 1.5× service pressure

□ Pressure held for specified duration (30-60 seconds typical)

□ Visual examination during test

□ Leak detection performed

STEP 4: Pass/Fail Determination

□ PASS: No leakage, no permanent deformation, no rupture

□ FAIL: Leakage detected, permanent expansion, visible damage, rupture

STEP 5: Post-Test Actions

For passed units:

□ Complete drying (internal and external)

□ Reassembly with new components

□ Recharge with proper agent

□ New service tag application

□ Return to service

For failed units (NFPA 10 Section 8.3.5):

□ Equipment condemned

□ Destruction performed

□ Destruction certificate issued

□ Replacement equipment provided

□ Documentation maintained

Fire safety inspection incorporating testing verifies operational safety through actual pressure verification rather than assumption.

—

What Testing Reveals

Hydrostatic testing identifies structural issues invisible during fire safety inspection visual examinations:

Internal Corrosion:

- Rust formation inside vessel

- Pitting from chemical reactions

- Metal thickness reduction

- Structural compromise invisible externally

Stress Fractures:

- Micro-cracks from pressure cycles

- Welding seam degradation

- Material fatigue from age

- Stress concentration points

Deformation Susceptibility:

- Weakened vessel walls

- Reduced pressure tolerance

- Permanent expansion under test pressure

- Safety margin elimination

Manufacturing Defects:

- Hidden welding flaws

- Material inconsistencies

- Pressure vessel construction issues

- Quality control failures

Environmental Damage:

- Salt air corrosion (coastal facilities)

- Chemical exposure degradation

- Temperature cycling effects

- Moisture infiltration damage

Fire safety inspection visual examination cannot detect these issues. Testing provides definitive verification.

—

Pass/Fail Statistics

Industry testing data from certified facilities:

Typical failure rates by equipment age:

| Equipment Age | Failure Rate | Primary Failure Cause |

|---|---|---|

| 5-7 years | 10-15% | Manufacturing defects, early corrosion |

| 8-10 years | 15-25% | Internal corrosion progression |

| 11-15 years | 25-40% | Age-related metal fatigue, corrosion |

| 16+ years | 40-60% | Advanced corrosion, structural degradation |

Fire safety inspection implications:

- Significant percentage of equipment fails testing despite appearing functional

- Failure rates increase with age

- Visual inspection cannot predict test outcomes

- Testing prevents unsafe equipment remaining in service

48Fire fire safety inspection testing services identify structurally compromised equipment before failure occurs during emergency use.

—

RISK MANAGEMENT DIMENSION

The Liability Protection Value

Fire safety inspection programs incorporating testing provide legal and financial risk management.

—

Equipment Failure Liability

Scenario: Untested extinguisher fails during use

Potential consequences:

- Equipment rupture during discharge

- Operator injury from vessel failure

- Fire suppression failure (equipment non-functional)

- Property damage from uncontrolled fire

- Liability exposure for inadequate maintenance

Legal examination focus:

- Was equipment tested per NFPA requirements?

- Does fire safety inspection documentation exist?

- Can testing compliance be verified?

- Were qualified service providers used?

Without testing compliance:

- Negligence claims strengthened

- Maintenance adequacy questioned

- Regulatory violation evident

- Liability exposure increased

- Insurance coverage complications

With testing compliance:

- Due diligence demonstrated

- NFPA compliance verified

- Professional service documented

- Liability defense supported

- Insurance acceptance maintained

Fire safety inspection programs including 48Fire testing services provide documented compliance reducing liability exposure.

—

Insurance Requirement Satisfaction

Insurance carriers evaluate fire safety inspection quality during underwriting:

Underwriting assessment includes:

□ Hydrostatic testing compliance verification

□ Testing frequency per NFPA standards

□ Service provider qualifications

□ Documentation completeness

□ Failed equipment replacement protocols

Premium implications:

Insufficient testing compliance:

- Risk assessment: Higher exposure

- Premium adjustment: Surcharge likely

- Coverage: Potential limitations

- Claims: Investigation intensive

Complete testing compliance:

- Risk assessment: Lower exposure

- Premium adjustment: Favorable consideration

- Coverage: Full acceptance

- Claims: Smooth processing

Fire safety inspection documentation including testing records supports insurance acceptance and may influence premium calculations.

—

Regulatory Violation Prevention

Fire safety inspection citations frequently involve testing non-compliance:

Common violations:

- Equipment exceeding test intervals

- No testing documentation available

- Unqualified testing providers used

- Failed equipment remaining in service

- Records not maintained per NFPA 10 Section 8.3.3

Violation costs:

Fire marshal citations:

- Typical penalty: $500-2,000 per violation

- Correction order issued

- Re-inspection required

- Enhanced monitoring possible

OSHA violations (29 CFR 1910.157(g)(1)):

- Serious violation: Up to $16,131

- Documentation correction mandated

- Follow-up inspection required

- Enhanced monitoring period

Insurance implications:

- Premium increases following citations

- Coverage limitations possible

- Claims processing complications

- Underwriting scrutiny increased

Fire safety inspection programs with systematic testing through 48Fire prevent violations through automated compliance tracking and timely testing completion.

—

PROGRAM IMPLEMENTATION DIMENSION

Building Comprehensive Fire Safety Inspection Systems

Effective fire safety inspection integrates testing within broader compliance framework.

—

Testing Schedule Management

Systematic approach to compliance:

Equipment Inventory:

□ All extinguisher locations documented

□ Equipment types recorded

□ Manufacturing dates captured

□ Serial numbers tracked

Test Interval Calculation:

□ First test due date determined (5 or 12 years from manufacture)

□ Subsequent test intervals established

□ Due dates calculated automatically

□ Advance notifications programmed

Proactive Scheduling:

□ Testing scheduled 6-12 months before deadline

□ Service coordinated with 48Fire

□ Temporary equipment arranged

□ Operational impact minimized

□ Budget allocation planned

Automated Tracking:

□ Digital system monitors due dates

□ Management alerts generated

□ Inspector notifications sent

□ Compliance status visible

□ Deadline violations prevented

Fire safety inspection programs benefit from 48Fire digital tracking systems preventing compliance gaps through automated management.

—

Service Provider Selection

Fire safety inspection compliance requires qualified testing providers:

NFPA 10 Section 8.1 requirements:

- Trained personnel

- Suitable testing equipment

- Appropriate facilities

- Proper procedures

Provider qualification verification:

48Fire certified testing capabilities:

□ Technician training documentation

□ Testing equipment calibration records

□ Facility certification credentials

□ Insurance and liability coverage

□ NFPA procedure compliance

□ Digital documentation systems

Compliance assurance:

- Testing performed per NFPA standards

- Documentation satisfies Section 8.3.3

- Qualified personnel verified

- Professional liability coverage maintained

Fire safety inspection programs utilizing 48Fire ensure testing compliance through certified facility utilization.

—

Failed Equipment Protocols

NFPA 10 Section 8.3.5 requires failed equipment destruction:

Compliance protocol:

STEP 1: Fail Determination

□ Testing reveals structural compromise

□ Equipment fails pressure test

□ Permanent deformation detected

□ Safety no longer verified

STEP 2: Condemnation

□ Equipment declared unsafe

□ Removal from service permanent

□ No repair attempts permitted

□ Destruction required

STEP 3: Physical Destruction

□ Vessel rendered unusable

□ Proper disposal performed

□ Destruction certificate issued

□ Documentation maintained

STEP 4: Replacement

□ New equipment provided by 48Fire

□ Equivalent type and rating

□ Proper mounting location

□ Service documentation complete

Fire safety inspection integrity maintained through proper failed equipment handling preventing unsafe units from returning to service.

—

INTEGRATION WITH BROADER FIRE SAFETY INSPECTION

The Comprehensive Compliance Model

Hydrostatic testing functions as component within complete fire safety inspection framework.

—

Multi-Level Inspection Structure

LEVEL 1: Monthly Visual Inspections

- Frequency: 30-day intervals

- Scope: NFPA 10 Section 7.2.1.1 eight criteria

- Purpose: Immediate functionality verification

- Documentation: Fire extinguisher inspection tags

LEVEL 2: Annual Maintenance

- Frequency: 12-month intervals

- Scope: NFPA 10 Section 7.3 complete maintenance

- Purpose: Component service and replacement

- Documentation: Service tags per Section 7.3.4

LEVEL 3: Six-Year Internal Examination

- Frequency: Six-year intervals

- Scope: NFPA 10 Section 7.3.1 complete disassembly

- Purpose: Internal vessel inspection

- Documentation: Examination records

LEVEL 4: Hydrostatic Testing

- Frequency: 5 or 12 years per Table 8.3.1

- Scope: NFPA 10 Section 8 pressure testing

- Purpose: Structural integrity verification

- Documentation: Permanent test records

Fire safety inspection programs integrate all four levels ensuring comprehensive compliance across inspection, maintenance, examination, and testing requirements.

—

Digital Documentation Integration

48Fire fire safety inspection digital platform integrates:

Equipment Management:

- Complete inventory database

- Location mapping

- Equipment specifications

- Age tracking automated

Inspection Tracking:

- Monthly inspection scheduling

- Criteria examination documentation

- Photographic evidence storage

- Deficiency management

Maintenance Records:

- Annual service documentation

- Six-year examination records

- Component replacement history

- Service tag information

Testing Documentation:

- Test due date tracking

- Testing schedule coordination

- Test results storage

- Pass/fail history

- Replacement documentation

Audit Reporting:

- Instant compliance reports

- Complete history accessible

- Regulatory requirement verification

- Management dashboard visibility

Fire safety inspection compliance simplified through integrated digital documentation eliminating manual tracking and providing continuous verification.

—

MEASURING COMPLIANCE VALUE

Quantifying Fire Safety Inspection Benefits

—

Compliance Metrics

Testing integration improves fire safety inspection measurable outcomes:

Regulatory Compliance:

- NFPA 10 Section 8 requirement satisfaction: 100%

- OSHA 29 CFR 1910.157(g)(1) compliance: Verified

- Fire marshal inspection results: Zero testing violations

- Citation avoidance: Regulatory penalties prevented

Safety Assurance:

- Equipment structural integrity: Verified through testing

- Failed equipment identification: 15-40% detected (age-dependent)

- Unsafe equipment removal: Before emergency use failure

- Operator safety: Enhanced through verified equipment

Risk Management:

- Liability exposure: Reduced through documented compliance

- Insurance acceptance: Testing documentation supports

- Legal defense: Due diligence demonstrated

- Professional service: Qualified provider utilized

Operational Efficiency:

- Testing schedule: Automated tracking prevents gaps

- Compliance status: Real-time visibility

- Budget planning: Predictable testing costs

- Audit readiness: Continuous documentation

Fire safety inspection programs incorporating testing demonstrate superior compliance across all measured dimensions.

—

CONCLUSION

The Testing-Compliance Connection

Routine extinguisher testing supports fire safety inspection compliance through:

Regulatory Compliance:

- NFPA 10 Section 8 mandatory requirements satisfied

- OSHA 29 CFR 1910.157(g)(1) compliance verified

- Testing intervals per Table 8.3.1 maintained

- Documentation per Section 8.3.3 complete

Operational Safety:

- Structural integrity verified through pressure testing

- Internal defects invisible to visual inspection detected

- Failed equipment (15-40%) identified and removed

- Operator safety enhanced through verified equipment

Risk Management:

- Liability exposure reduced through documented compliance

- Insurance requirements satisfied with testing records

- Regulatory violations prevented through systematic testing

- Professional service provider utilization documented

Program Implementation:

- Automated testing schedule management

- Qualified provider (48Fire) certification verified

- Failed equipment protocols per Section 8.3.5 followed

- Digital documentation integration maintained

Compliance Value:

- Zero testing-related violations

- 100% NFPA Section 8 compliance

- Complete audit-ready documentation

- Continuous regulatory verification

48Fire fire safety inspection services provide comprehensive testing programs including NFPA 10-compliant hydrostatic testing, certified facility utilization, complete documentation systems, automated schedule tracking, and failed equipment replacement—ensuring fire safety inspection compliance through verified structural integrity testing.

[Implement Comprehensive Fire Safety Inspection Program](/contact-us)

—

48Fire

Fire Safety Inspection Services Including Hydrostatic Testing

NFPA Compliance • Certified Testing • Complete Documentation

Contact: [/contact-us](/contact-us)