How Proper Documentation Prevented a Failed Safety Audit

—

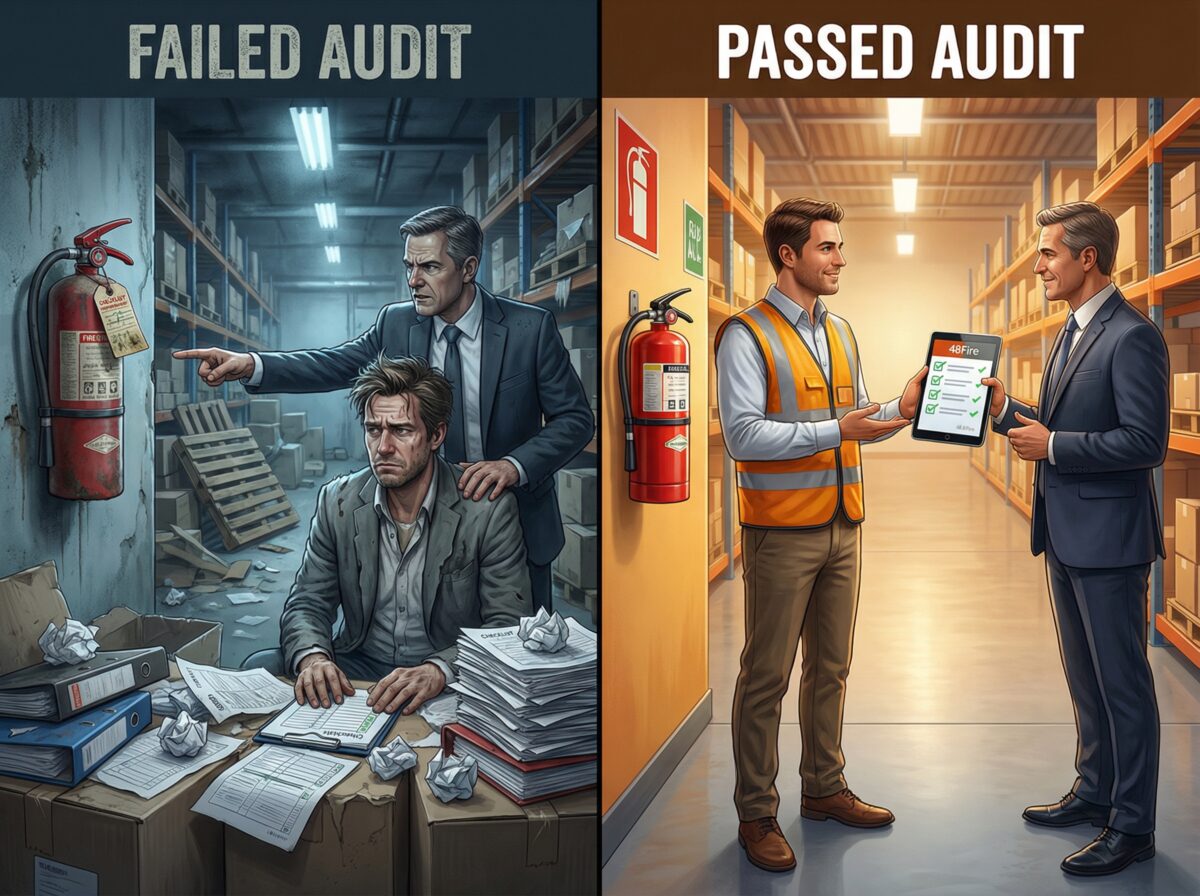

TWO FACILITIES, ONE AUDIT, DIFFERENT OUTCOMES

Same day. Same auditor. Two distribution centers. Identical fire protection equipment. Opposite results.

Facility A: The Documentation Gap

Tuesday 9:00 AM – Safety audit begins

Third-party safety auditor arrives at 180,000 sq ft distribution center. Fire protection assessment standard procedure. 120 fire extinguishers throughout facility.

Auditor request: “Please provide your fire extinguisher inspection checklist records for the past 12 months.”

Facility manager produces:

- Binder with some inspection forms

- Forms completed inconsistently

- Several months missing

- No service provider documentation

- Generic service tags on equipment

- Verbal assurance “everything gets checked”

Auditor examination of equipment:

- Service tags lack specific dates

- No technician identification on tags

- Cannot verify when maintenance actually performed

- Fire extinguisher inspection checklist data incomplete

- Cannot confirm NFPA 10 compliance

Audit findings (deficiencies identified):

- Inadequate documentation of monthly inspections

- Cannot verify annual maintenance occurred

- Service provider qualifications unverified

- NFPA 10 Section 7.2.2 documentation requirement not met

- OSHA 1910.157(e)(3) compliance questionable

Audit result: FAILED – Major deficiencies requiring immediate correction

Correction requirements:

- Implement compliant fire extinguisher inspection checklist system

- Obtain retroactive service documentation

- Third-party verification required

- Re-audit within 60 days

- Estimated correction cost: $8,500-12,000

—

Facility B: The Documentation Advantage

Tuesday 2:00 PM – Same auditor, different facility

Second distribution center, similar size, similar equipment quantity (115 fire extinguishers).

Auditor request: “Please provide your fire extinguisher inspection checklist records.”

Facility manager provides immediate digital access:

- Complete 12-month fire extinguisher inspection checklist history

- Every unit documented with photos

- All inspection dates recorded

- Service provider credentials included (48Fire)

- Technician certifications accessible

- NFPA compliance verification available

Auditor examination of equipment:

- Service tags complete with all NFPA 10 Section 7.3.4 requirements

- Dates, technician names, certification numbers present

- Can verify exactly when each service occurred

- Fire extinguisher inspection checklist data comprehensive

- Digital records match physical tags perfectly

Auditor questions answered immediately:

- “When was this unit last serviced?” – Instant answer with photo documentation

- “Who performed the service?” – Certified technician identified with credentials

- “How do you track inspection deadlines?” – Automated system demonstration

- “Can you show NFPA compliance?” – Complete documentation provided

Audit findings: PASSED – All requirements satisfied, exemplary documentation practices noted

Audit result: No deficiencies. No corrections required. Commendation for documentation quality.

The difference: Comprehensive fire extinguisher inspection checklist system with complete documentation vs. incomplete informal tracking.

This article explains how proper fire extinguisher inspection checklist implementation prevents audit failures, satisfies regulatory requirements, and protects facilities from violations.

—

WHY DOCUMENTATION MATTERS

Regulatory Requirements for Fire Extinguisher Inspection Checklist

NFPA 10 Section 7.2.2 explicitly requires documentation:

“Manual or electronic records shall be maintained to provide evidence that the required inspections have been performed.”

What this means:

- Inspections must be documented

- Records must be maintained

- Evidence must prove inspections occurred

- Fire extinguisher inspection checklist satisfies requirement

OSHA 1910.157(e)(3) requires:

“The employer shall assure that portable fire extinguishers are subjected to an annual maintenance check.”

Documentation proves:

- Annual maintenance actually occurred

- Qualified personnel performed service

- Requirements satisfied within timeframes

- Employer fulfilled responsibility

Without proper fire extinguisher inspection checklist:

- Cannot prove inspections occurred

- Cannot verify maintenance timing

- Cannot demonstrate compliance

- Regulatory violations likely during audits

—

What Auditors Actually Examine

Third-party safety audits assess fire extinguisher inspection checklist quality:

Documentation completeness:

- Are all required inspections documented?

- Do records cover required timeframes?

- Is information complete and accurate?

- Can compliance be verified?

Record accessibility:

- Can documentation be produced immediately?

- Are records organized systematically?

- Is historical data preserved?

- Can specific information be located quickly?

Verification capability:

- Do records match physical equipment?

- Can inspection dates be confirmed?

- Are service providers identifiable?

- Can technician qualifications be verified?

Compliance demonstration:

- Do records satisfy NFPA 10 requirements?

- Does documentation meet OSHA standards?

- Are all regulatory elements present?

- Can continuous compliance be proven?

Fire extinguisher inspection checklist systems that fail audits:

- Incomplete records (missing inspections)

- Informal documentation (no systematic approach)

- Inaccessible information (cannot locate quickly)

- Unverifiable claims (no supporting evidence)

Fire extinguisher inspection checklist systems that pass audits:

- Complete documentation (all inspections recorded)

- Systematic approach (consistent format)

- Immediate accessibility (organized, searchable)

- Full verification (supporting evidence present)

—

ESSENTIAL FIRE EXTINGUISHER INSPECTION CHECKLIST COMPONENTS

Monthly Inspection Documentation

NFPA 10 Section 7.2 requires monthly inspections with documentation per Section 7.2.2.

Comprehensive fire extinguisher inspection checklist includes:

Equipment identification:

- Location (building, floor, room, specific position)

- Serial number or asset tag

- Type and size

- Manufacturing date

- Last service date

Inspection criteria verification:

□ Located in designated place

□ Access not obstructed

□ Operating instructions legible

□ Pressure gauge in operable range

□ Fullness verified (weight/heft)

□ No obvious damage, corrosion, leakage

□ Hose and nozzle not damaged

□ Seals and tamper indicators intact

Inspection documentation:

- Date inspection performed

- Inspector name/initials

- Pass/fail status

- Deficiencies noted (if any)

- Follow-up actions required

Photographic evidence:

- Gauge reading

- Overall unit condition

- Any deficiencies identified

- Location verification

—

Annual Maintenance Documentation

NFPA 10 Section 7.3.4 requires service tags documenting maintenance:

“Maintenance shall be indicated by the attachment of a service tag or label to the extinguisher. The tag shall include the following information: (1) Month and year maintenance was performed, (2) Name of person or agency performing service, (3) Name of agency.”

Fire extinguisher inspection checklist for annual maintenance includes:

Service tag information:

- Service date (month and year)

- Service provider name (48Fire)

- Technician name or certification number

- Service type performed

- Next service due date

Service documentation:

- Work performed description

- Components replaced

- Agent recharged (if applicable)

- Internal examination performed (if applicable)

- Testing conducted (if applicable)

Technician credentials:

- NFPA certification verification

- Certification number

- Certification expiration date

- Training completion records

Quality verification:

- Before service photos

- During service documentation

- After service photos

- Verification signatures

—

Six-Year and Hydrostatic Testing Documentation

NFPA 10 Section 8.3.3 requires testing records:

“Permanent records shall be maintained to provide evidence that the hydrostatic tests have been performed at the time intervals specified in Table 8.3.1.”

Fire extinguisher inspection checklist for testing includes:

Test documentation:

- Test date

- Testing facility identification

- Test pressure used

- Test duration

- Pass/fail result

- Internal examination findings

Failed unit documentation:

- Failure description

- Destruction certification per NFPA 10 Section 8.3.5

- Replacement unit information

- Disposal documentation

Passed unit documentation:

- Recharge information

- Service tag application

- Return to service date

- Next test due date

—

DIGITAL VS. PAPER FIRE EXTINGUISHER INSPECTION CHECKLIST

Paper-Based Systems

Traditional fire extinguisher inspection checklist approach:

Advantages:

- Simple implementation

- No technology required

- Familiar to staff

- Low initial investment

Limitations:

- Easy to lose or damage

- Difficult to search historical data

- Cannot access remotely

- No automatic deadline tracking

- Time-consuming compilation for audits

- No photographic documentation

- Prone to incomplete entries

Audit performance:

- Acceptable if meticulously maintained

- Often reveals gaps during examination

- Difficult to produce comprehensive reports

- Cannot verify information quickly

—

Digital Fire Extinguisher Inspection Checklist Systems

Modern approach (48Fire provides):

Capabilities:

- Cloud-based accessibility (24/7 from anywhere)

- Automatic deadline tracking and notifications

- Photographic documentation integrated

- GPS location verification

- Real-time compliance status

- Instant report generation

- Complete historical records

- Searchable database

Audit advantages:

- Immediate documentation production

- Comprehensive reports on demand

- Photo evidence supporting claims

- Verification of service dates and locations

- Technician credential access

- Compliance status demonstration

- Professional presentation

Compliance benefits:

- Zero missed inspections (automated reminders)

- Complete documentation (system requires all fields)

- Permanent records (cloud storage)

- Audit-ready reports (generated instantly)

—

IMPLEMENTING EFFECTIVE FIRE EXTINGUISHER INSPECTION CHECKLIST

Assessment Phase

Step 1: Current documentation evaluation

Assess existing fire extinguisher inspection checklist quality:

- What documentation currently exists?

- Is it complete and consistent?

- Does it satisfy NFPA 10 requirements?

- Can it pass audit examination?

- What gaps exist?

Common findings:

- Incomplete monthly inspection records

- Missing service provider documentation

- No technician credential verification

- Inadequate historical records

- Disorganized filing systems

—

Step 2: Requirement identification

Determine complete fire extinguisher inspection checklist needs:

- NFPA 10 Section 7.2.2 inspection documentation

- NFPA 10 Section 7.3.4 maintenance tags

- NFPA 10 Section 8.3.3 testing records

- OSHA 1910.157 compliance documentation

- Insurance carrier requirements

- Internal audit requirements

—

Implementation Phase

Step 3: System selection

Choose appropriate fire extinguisher inspection checklist approach:

Paper-based system:

- Suitable for: Small facilities, limited budgets, simple needs

- Requires: Disciplined consistent use, organized filing, regular review

Digital system:

- Suitable for: All facility sizes, quality documentation priority, audit preparation

- Provides: Automated tracking, comprehensive records, instant accessibility

48Fire digital fire extinguisher inspection checklist:

- Complete NFPA requirement satisfaction

- Automated deadline management

- Photographic documentation

- Technician credential integration

- Instant audit report generation

—

Step 4: Training and rollout

Implement fire extinguisher inspection checklist systematically:

Staff training:

- Inspection criteria understanding

- Fire extinguisher inspection checklist completion procedures

- Documentation importance explanation

- System access and navigation

- Quality standards expectations

Service provider coordination:

- Documentation requirements communication

- Service tag specifications

- Credential verification procedures

- Digital system integration (if applicable)

Initial documentation:

- Complete equipment inventory

- Baseline inspection of all units

- Historical data compilation (if available)

- System population with current information

—

Maintenance Phase

Step 5: Ongoing documentation quality

Maintain fire extinguisher inspection checklist integrity:

Monthly inspection execution:

- Scheduled systematic inspections

- Complete fire extinguisher inspection checklist for each unit

- Photographic documentation

- Deficiency identification and tracking

- Follow-up action verification

Annual maintenance coordination:

- Scheduled service before deadlines

- Complete service documentation

- Service tag verification

- Technician credential confirmation

- Digital record updates

Periodic review:

- Quarterly documentation audits (internal)

- Completeness verification

- Gap identification and correction

- System effectiveness assessment

- Continuous improvement implementation

—

AUDIT PREPARATION USING FIRE EXTINGUISHER INSPECTION CHECKLIST

30 Days Before Audit

Documentation review:

- Pull complete fire extinguisher inspection checklist records

- Verify 12+ months of inspection documentation

- Confirm all service dates within required intervals

- Check service provider credentials accessible

- Ensure testing documentation current

Gap identification:

- Identify any missing inspections

- Locate incomplete documentation

- Find outdated service tags

- Note credential verification issues

- Determine correction needs

Gap correction:

- Complete missing inspections immediately

- Obtain missing service documentation

- Schedule overdue maintenance

- Update incomplete records

- Verify all information accurate

—

7 Days Before Audit

Final verification:

- Run complete compliance report from fire extinguisher inspection checklist system

- Review for any remaining gaps

- Confirm all documentation accessible

- Prepare audit presentation materials

- Brief facility staff on audit procedures

Organization:

- Organize physical records (if paper-based)

- Test digital system access (if electronic)

- Prepare equipment location maps

- Compile service provider credentials

- Ready photo documentation

—

During Audit

Documentation presentation:

- Provide immediate fire extinguisher inspection checklist access

- Demonstrate system capabilities (digital)

- Answer questions with supporting documentation

- Show photographic evidence

- Verify technician credentials

Equipment verification:

- Walk auditor through facility systematically

- Match physical equipment to fire extinguisher inspection checklist records

- Demonstrate service tag information

- Explain documentation process

- Address any questions comprehensively

—

COST OF POOR DOCUMENTATION VS. PROPER SYSTEM

Failed Audit Correction Costs

When inadequate fire extinguisher inspection checklist fails audit:

Immediate costs:

- Audit failure fee/penalty: $500-2,000

- Emergency documentation correction: $2,000-4,000

- Retroactive service verification: $1,500-3,000

- System implementation (rushed): $3,000-5,000

- Re-audit fee: $500-1,000

Ongoing costs:

- Enhanced inspection frequency: +$1,000-2,000 annually

- Third-party verification requirement: $2,000-4,000 annually

- Insurance premium impact: +5-15% ($1,500-4,500 for $30K premium)

Total first-year cost: $12,000-25,500

—

Proper Fire Extinguisher Inspection Checklist Investment

Implementing quality system proactively:

Digital system (48Fire):

- Setup and training: $1,500-2,500

- Ongoing service including documentation: $3,600-6,000 annually (100 units)

- No audit failure costs

- No correction expenses

- No insurance complications

Paper system (DIY):

- Forms and organization: $200-500

- Staff time: 10-15 hours monthly

- Service provider documentation: Included in service

- Annual cost: $1,500-2,500 (if maintained properly)

Cost comparison (5-year):

Without proper system:

- Audit failures (probability 60-80%): $12,000-25,500

- Insurance impact: $7,500-22,500

- Ongoing complications: $5,000-10,000

- Total 5-year: $24,500-58,000

With proper fire extinguisher inspection checklist:

- System implementation: $1,500-2,500

- Ongoing documentation: $18,000-30,000

- Audit success: No penalties

- Insurance optimization: Potential savings

- Total 5-year: $19,500-32,500

Net savings: $5,000-25,500 over 5 years

—

BEST PRACTICES FOR FIRE EXTINGUISHER INSPECTION CHECKLIST

Documentation Excellence

Monthly inspections:

- Same day each month (consistency)

- Same systematic route through facility

- Complete fire extinguisher inspection checklist for every unit

- Photo documentation of any issues

- Immediate deficiency follow-up

Service coordination:

- Schedule maintenance before deadlines

- Verify service provider credentials

- Confirm service tag application

- Obtain complete service documentation

- Update digital records immediately

Record maintenance:

- Retain all documentation permanently

- Back up digital systems regularly

- Organize paper records systematically

- Review quarterly for completeness

- Correct gaps immediately

—

Common Documentation Mistakes to Avoid

Incomplete entries:

❌ Skipping fire extinguisher inspection checklist fields

✓ Complete every field every time

Inconsistent timing:

❌ Irregular inspection intervals

✓ Consistent monthly schedule

Missing photos:

❌ Text-only documentation

✓ Photographic evidence for all inspections

Poor organization:

❌ Random filing, inaccessible records

✓ Systematic organization, instant accessibility

No verification:

❌ Accepting service without documentation

✓ Requiring complete service records

Credential gaps:

❌ Unknown service provider qualifications

✓ Verified technician certifications

—

CONCLUSION

Proper fire extinguisher inspection checklist implementation prevents audit failures by:

Satisfying regulatory requirements:

- NFPA 10 Section 7.2.2 inspection documentation

- NFPA 10 Section 7.3.4 maintenance tags

- NFPA 10 Section 8.3.3 testing records

- OSHA 1910.157 compliance demonstration

Providing audit-ready documentation:

- Complete inspection records (all units, all dates)

- Service provider credentials verified

- Technician qualifications confirmed

- Photographic evidence supporting claims

- Instant accessibility for examinations

Preventing costly failures:

- Audit failure correction: $12,000-25,500 avoided

- Insurance complications: $7,500-22,500 saved

- Regulatory penalties: $500-2,000 prevented

- Management crisis response: Significant time saved

Investment comparison:

- Proper fire extinguisher inspection checklist system: $19,500-32,500 (5 years)

- Poor documentation audit failures: $24,500-58,000 (5 years)

- Net savings: $5,000-25,500

Case study outcomes:

- Facility A (inadequate documentation): FAILED audit, $8,500-12,000 corrections required

- Facility B (comprehensive fire extinguisher inspection checklist): PASSED audit, commendation received, zero corrections

48Fire comprehensive fire extinguisher inspection checklist systems provide complete NFPA documentation, automated deadline tracking, photographic evidence, technician credential verification, and instant audit-ready reports—ensuring facilities pass safety audits without deficiencies.

[Implement Professional Fire Extinguisher Inspection Checklist System](/contact-us)

—

48Fire

Fire Extinguisher Inspection Checklist Systems

Complete Documentation • NFPA Compliance • Audit-Ready Records

Contact: [/contact-us](/contact-us)