How One School District Streamlined Its Fire Equipment Testing

—

THE REALITY OF MULTI-SITE COMPLIANCE

Facilities Director’s Perspective

School district with distributed campuses. Hundreds of fire extinguishers. Documented compliance challenges.

Managing fire equipment across multiple school buildings creates coordination problems that single-site facilities never face.

Each building operates somewhat independently. Custodial staff turn over. Principals rotate. Service contracts expire and renew through procurement processes that prioritize lowest bid. Documentation lives in filing cabinets at individual schools. Central visibility? Limited at best.

Meanwhile, regulatory requirements don’t care about organizational complexity. NFPA 10 requires monthly inspections at 30-day intervals. Annual maintenance within 12 months. Six-year internal examinations. Hydrostatic testing at 5 or 12-year intervals depending on type.

The compliance question: How do you maintain systematic compliance across 15-25 school buildings when responsibility diffuses across dozens of people and vendors change every budget cycle?

This article examines real approaches that work—based on actual NFPA requirements, documented best practices, and practical implementation strategies used by educational facilities nationwide.

—

UNDERSTANDING THE MULTI-SITE CHALLENGE

The Distributed Facility Problem

Typical medium-large school district profile:

- 12-25 school buildings

- 400-1,000+ fire extinguishers total

- 30-75 extinguishers per elementary school

- 50-100 per middle school

- 100-200+ per high school

- Additional units in administrative buildings, maintenance facilities, transportation centers

The coordination complexity:

Unlike a single commercial building where one facilities manager oversees all equipment, school districts have:

- Individual principals responsible for their buildings

- Separate custodial staff at each location

- Central facilities/maintenance department with district-wide oversight

- Procurement processes that may involve multiple vendors

- Budget allocation across numerous cost centers

Where compliance breaks down:

Information doesn’t flow automatically between buildings and central office. Equipment at Building A receives timely service. Building B gets missed for six months before anyone notices. Central administration discovers gaps only during crisis—fire marshal inspections, insurance audits, or actual emergencies.

—

NFPA 10 Requirements That Don’t Change

Regardless of organizational complexity, standards remain:

Monthly Inspection (NFPA 10 Section 7.2):

- Visual check of all extinguishers at approximately 30-day intervals

- Documentation of date and person performing inspection

- Can be performed by trained facility personnel

Annual Maintenance (NFPA 10 Section 7.3):

- Comprehensive maintenance by certified technician within 12-month intervals

- Internal component examination

- Seal replacement

- Pressure verification

- Professional service tag application

Six-Year Internal Examination (NFPA 10 Section 7.3.1):

- Complete disassembly and internal inspection for stored pressure extinguishers

- Agent removal and internal vessel examination

- Component replacement as needed

- Recharge with proper agent

Hydrostatic Testing (NFPA 10 Section 8):

- Pressure vessel testing at intervals per NFPA 10 Table 8.3.1

- Every 5 years for CO2, water, foam

- Every 12 years for dry chemical stored pressure

- Performed at certified testing facility

The challenge isn’t understanding requirements—it’s implementing them systematically across multiple sites with changing personnel and vendors.

—

COMMON PROBLEMS IN MULTI-SITE MANAGEMENT

Problem #1: Documentation Fragmentation

What happens in distributed facilities:

Each school maintains its own records—or doesn’t. File formats vary. Paper logs get lost. Electronic records exist on individual computers. When staff leave, institutional knowledge disappears.

Real scenario:

New principal arrives at elementary school. Asks about fire extinguisher service. Predecessor maintained paper log in office. That log moved to storage during office cleaning. New principal doesn’t know log existed. Service company continues monthly visits, but school has no documentation of inspections.

Six months later, fire marshal requests inspection records. School produces nothing. Company has records but school verification missing. Creates documentation gap despite actual service occurring.

NFPA 10 Section 7.2.2 requirement:

“Manual or electronic records shall be maintained to provide a record that inspections have been performed at required frequencies.”

Documentation is part of compliance—not administrative nicety.

—

Problem #2: Vendor Rotation Through Procurement Cycles

Public institution procurement reality:

Many school districts must bid service contracts annually or bi-annually. Award goes to lowest responsible bidder meeting specifications.

What this creates:

Year 1: Vendor A provides service, establishes systems, learns facility layouts

Year 2: Vendor B wins rebid with lower price, starts learning process over

Year 3: Vendor A wins again, tries to reconstruct from old records

Year 4: Vendor C enters, no historical knowledge

Each vendor transition loses:

- Equipment service history

- Facility-specific knowledge (where units are, access procedures)

- Relationship with school staff

- Continuous documentation chain

The compliance impact:

When Vendor B takes over from Vendor A, equipment may show tags from Vendor A service 13 months ago. Vendor B performs annual maintenance but now equipment has 13-month gap before current vendor’s first service. NFPA requires 12-month maximum intervals.

These gaps accumulate during every transition.

—

Problem #3: Budget Constraints and Deferred Maintenance

Educational funding reality:

School budgets face pressures from instructional needs, facility repairs, technology, and dozens of competing priorities. Fire extinguisher maintenance seems less urgent than fixing HVAC or addressing leaking roofs.

What often happens:

Budget gets tight. Facilities director makes decision: “Defer fire extinguisher annual maintenance until next quarter” or “Skip six-year examinations this year, catch up next year.”

The problem:

NFPA deadlines don’t defer. Equipment due for 12-month annual maintenance in September needs service by September. Deferring to December creates 15-month gap—NFPA violation regardless of budget justification.

The accumulation:

Year 1: Defer 10% of maintenance

Year 2: Defer another 10% plus catch up on Year 1 (now 20% backlog)

Year 3: Budget allows only current year, backlog grows to 30%

Year 4: Fire marshal inspection discovers widespread non-compliance

Deferred maintenance doesn’t eliminate compliance requirements—just creates concentrated problems later.

—

Problem #4: Staff Knowledge Gaps

Personnel reality in schools:

- Principals typically rotate every 3-5 years

- Custodial staff turnover varies but can be significant

- Central facilities directors change with administrative transitions

- Designated safety coordinators get reassigned

The knowledge loss:

Person who “knew where all the extinguishers were” retires. Replacement doesn’t receive comprehensive orientation. Knowledge about service history, special requirements, or equipment locations exists only in departed employee’s memory.

Real impact:

New custodian at middle school doesn’t know fire extinguisher in storage room exists. Unit doesn’t appear on monthly inspection checklist (old custodian knew it was there without needing list). Equipment goes uninspected for year until professional service discovers it.

NFPA 10 Section 6.1.3.7 requires:

“The nameplates and instructional markings on fire extinguishers shall be kept clean and legible and shall face outward where extinguishers are wall mounted.”

But if nobody knows extinguisher exists, maintaining visibility becomes impossible.

—

SYSTEMATIC SOLUTIONS THAT WORK

Solution Component #1: Comprehensive Baseline Assessment

First step solving multi-site compliance: Know exactly what you have.

What comprehensive assessment involves:

Physical inventory:

- Visit every building

- Locate every extinguisher physically (not assume inventory accuracy)

- Document exact locations (building, floor, room, specific mounting position)

- Photograph each unit

- Record serial numbers and manufacturing dates

- Note current condition

Documentation audit:

- Gather existing service records from all buildings

- Review central files

- Collect vendor invoices and reports

- Identify documentation gaps

Compliance analysis:

- Compare actual status against NFPA requirements

- Calculate when annual maintenance last occurred

- Identify units overdue for six-year examinations

- Determine hydrostatic testing status based on manufacturing dates

- Flag immediate safety concerns (blocked access, low pressure, physical damage)

What this reveals:

Organizations consistently discover:

- 15-25% more equipment than inventory showed (units added over years, never recorded)

- 30-50% of equipment with overdue maintenance

- 10-20% missing documentation proving service occurred

- 5-10% with immediate problems requiring attention

Why this matters:

Can’t establish compliant program without knowing accurate starting point. Assumptions about equipment quantity, location, and status are usually wrong.

Professional service providers like 48Fire conduct these assessments systematically, creating digital inventories with photographic documentation establishing accurate baseline.

—

Solution Component #2: Unified Service Provider

The vendor fragmentation problem requires unified solution.

Why consolidated provider approach works:

Continuous documentation:

Service provider maintains complete historical records across years. No loss of information during transitions.

Facility knowledge retention:

Provider learns building layouts, access procedures, staff contacts. Knowledge accumulates rather than resetting with each contract.

Consistent processes:

Same inspection procedures, documentation formats, service standards apply across all locations.

Clear accountability:

One provider responsible for district-wide compliance. No ambiguity about who ensures requirements meet.

Procurement consideration:

Some districts concerned about single-source approach. Valid concern requiring contract terms protecting district interests:

- Performance metrics with measurable compliance targets

- Annual pricing reviews against market rates

- Termination clauses if service quality deteriorates

- Documented service level agreements

Many educational facilities find consolidated provider relationships work better than constant rebidding when properly structured with accountability mechanisms.

—

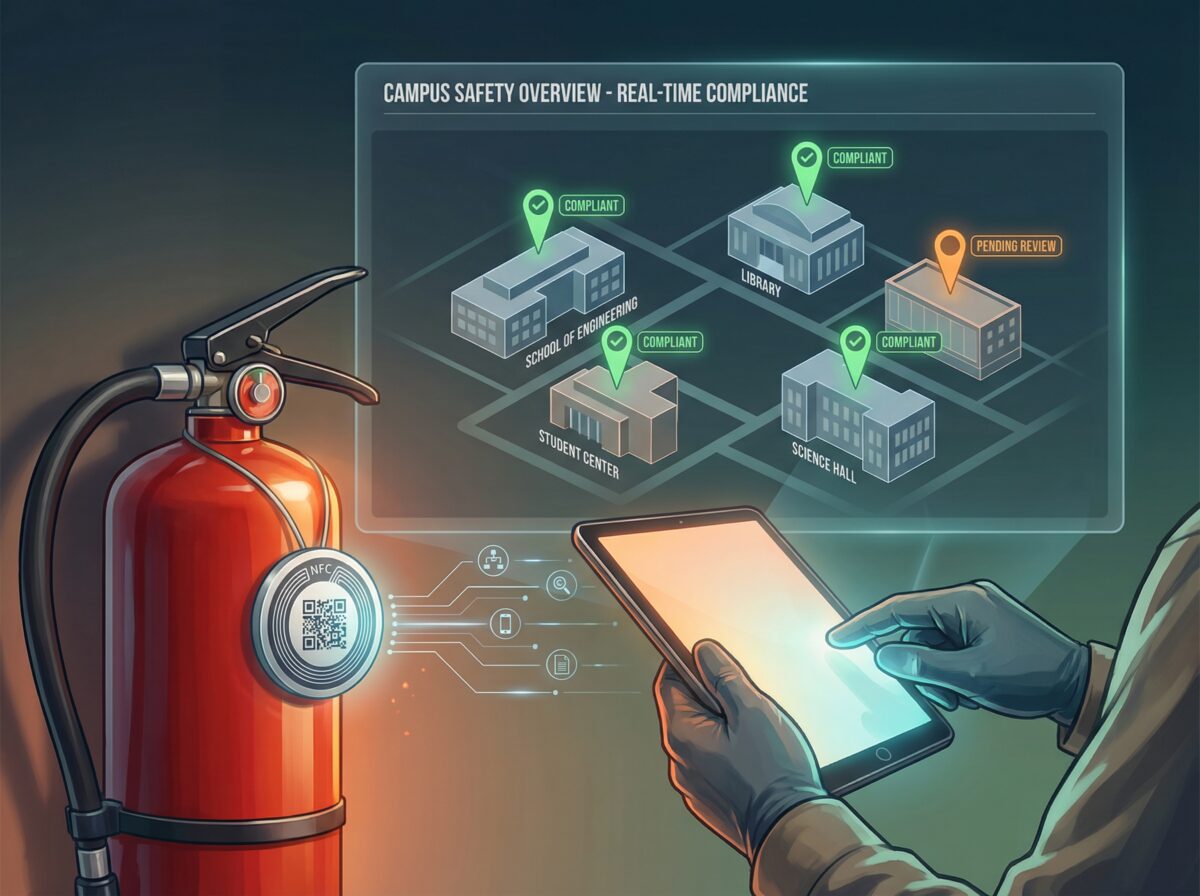

Solution Component #3: Digital Tracking Systems

Paper documentation and spreadsheets fail at scale.

What digital tracking provides:

Centralized database:

All equipment information in one system accessible to authorized users across district

Real-time updates:

As technicians complete inspections or service, records update immediately

Automated deadline tracking:

System calculates when next service due based on NFPA intervals, alerts before deadlines

Compliance visibility:

Dashboard showing district-wide status—percentage compliant, units requiring attention, upcoming deadlines

Location-specific views:

Principal sees only their building’s equipment and status

Historical records:

Complete service history for each extinguisher over entire life span

Report generation:

Automatic creation of compliance reports for board meetings, insurance carriers, state inspections

Mobile access:

Facilities staff check status from anywhere via smartphone or tablet

Why this matters:

Fire marshal arrives unannounced at high school. Principal logs into system on phone, pulls up complete documentation for building’s 156 extinguishers, shows all current within NFPA intervals with photographic evidence from last inspection. Inspection proceeds smoothly.

Without digital system: Principal searches filing cabinet, finds incomplete paper logs, can’t definitively prove compliance, inspection becomes problematic.

Technology exists making this practical. Cloud-based platforms designed specifically for multi-location fire equipment management eliminate manual tracking burdens.

—

Solution Component #4: Automated Scheduling

Manual scheduling across 15-25 buildings guarantees missed deadlines.

What automated scheduling provides:

NFPA interval calculations:

System tracks last service date, automatically calculates when next service due per NFPA requirements

Advance notifications:

Alerts sent 30-60 days before deadlines to facilities director, building principals, service provider

Coordinated routing:

Service provider schedules visits efficiently—all nearby schools on similar dates, reducing travel time

Buffer periods:

Service scheduled 11 months after last annual maintenance, not 12—prevents deadline violations from minor delays

School calendar integration:

Testing scheduled during summer when buildings less occupied, avoiding disruption during instructional days

Exception handling:

When school closed unexpectedly (snow day, facility issue), system automatically reschedules maintaining compliance

Why this matters:

Elementary School #12 had annual maintenance last performed March 2024. Automated system schedules next service for February 2025 (11-month interval). Advance notification goes to principal and facilities director January 2025. Service occurs on schedule. NFPA 12-month requirement satisfied with buffer.

Without automation: Facilities director manually tracks 400+ service deadlines across district. Some get missed. Violations occur not from intent but from complexity overwhelming manual tracking.

—

Solution Component #5: Professional Monthly Inspection Service

NFPA 10 allows trained facility staff to perform monthly inspections, but practical challenges exist.

School staff monthly inspection challenges:

Competing priorities:

Custodial staff have full-time responsibilities—cleaning, maintenance, student supervision. Adding monthly fire equipment inspection to already-full workload creates reliability issues.

Turnover impact:

When trained custodian leaves, replacement needs training. During gaps, inspections get missed.

Documentation inconsistency:

Different staff use different forms, document differently, create inconsistent records.

Technical knowledge limits:

Staff may not recognize subtle pressure gauge issues, early corrosion, mounting problems requiring professional attention.

Professional monthly inspection alternative:

Certified technicians visit monthly:

Consistent schedule (e.g., every 2nd Tuesday), same technician familiar with facility

Systematic documentation:

Digital inspection with photographic evidence, GPS verification, standardized format

Issue detection:

Professional eyes catch problems facility staff miss—slight pressure loss, early equipment degradation, compliance gaps

Immediate service:

Many issues resolvable during inspection visit—recharge low-pressure unit, replace damaged hose, correct mounting problems

Reduced facility burden:

School staff focus on core responsibilities, professional service handles technical fire equipment compliance

Cost consideration:

Professional monthly inspection costs more than internal staff time. But comparison should include:

- Reliability (professional service doesn’t call in sick or get pulled to other duties)

- Documentation quality (professional standard vs. variable internal)

- Issue detection (professionals catch problems sooner)

- Compliance assurance (certified service reduces violation risk)

Many educational facilities choose professional monthly inspection valuing reliability and compliance assurance over cost savings from internal programs.

—

IMPLEMENTATION APPROACH

Phase 1: Assess Current Reality

Actions:

- Conduct comprehensive physical inventory across all buildings

- Audit existing documentation and identify gaps

- Analyze compliance status against NFPA requirements

- Calculate costs for bringing equipment to full compliance

Timeline: 2-4 weeks depending on facility count and equipment quantity

Outcome: Accurate understanding of current status, specific deficiencies, correction requirements, realistic budget needs

—

Phase 2: Develop Compliance Plan

Actions:

- Prioritize deficiencies (immediate safety issues vs. documentation gaps vs. overdue service)

- Create correction timeline

- Develop budget proposal

- Design ongoing systematic program preventing future gaps

Timeline: 1-2 weeks

Outcome: Board-ready proposal with clear scope, budget, timeline, expected results

—

Phase 3: Correct Existing Deficiencies

Actions:

- Address immediate safety concerns (non-functional equipment, blocked access)

- Complete overdue annual maintenance

- Process hydrostatic testing backlog

- Establish proper documentation throughout

Timeline: 4-12 weeks depending on scope

Outcome: All equipment compliant with NFPA requirements, documented service history established

—

Phase 4: Implement Systematic Program

Actions:

- Establish regular inspection schedule across all buildings

- Set up digital tracking and reporting systems

- Train building staff on procedures and access

- Implement automated scheduling and deadline tracking

Timeline: 4-8 weeks

Outcome: Ongoing program operating automatically, maintaining continuous compliance

—

Phase 5: Monitor and Maintain

Actions:

- Regular compliance reporting to district leadership

- Periodic verification of service quality

- Annual program review and optimization

- Budget planning for equipment replacement cycles

Timeline: Ongoing

Outcome: Sustained compliance with minimal administrative burden

—

REALISTIC COST EXPECTATIONS

Initial Implementation Investment

Comprehensive assessment: $800-2,000 (varies with facility count)

Compliance correction costs depend on current status:

Minor deficiencies (70-80% already compliant):

$3,000-8,000 for catch-up maintenance and documentation

Moderate deficiencies (50-70% compliant):

$8,000-15,000 for comprehensive corrections

Major deficiencies (under 50% compliant):

$15,000-30,000+ for extensive catch-up work

Factors affecting correction costs:

- Equipment quantity requiring service

- Hydrostatic testing backlog (testing costs $50-75 per unit)

- Equipment replacement needs (some units may be beyond service life)

- Documentation establishment requirements

—

Ongoing Annual Program Costs

Factors affecting ongoing costs:

Equipment quantity:

- 200-400 extinguishers: $4,000-8,000 annually

- 400-700 extinguishers: $8,000-14,000 annually

- 700-1,000+ extinguishers: $14,000-20,000+ annually

Service level:

- Monthly inspections by facility staff + annual professional maintenance: Lower cost

- Monthly professional inspection + annual maintenance: Higher cost, higher reliability

Geographic distribution:

Concentrated facilities cost less per unit (efficient routing) than widely dispersed campuses

Realistic expectation: $15-30 per extinguisher annually for complete NFPA-compliant program including professional service

—

Cost Avoidance Through Compliance

OSHA violation penalties (current 2025 rates):

- Serious violation: Up to $16,131 per violation

- Multiple violations typical when inspectors find systemic non-compliance

- Potential exposure: $30,000-80,000+ for significant deficiencies

Fire marshal citations:

- Vary by jurisdiction

- Typically $500-5,000 per violation

- Can include re-inspection fees and operational restrictions

Insurance complications:

- Premium increases when underwriters discover poor maintenance

- Claim complications if fire occurs with non-compliant equipment

- Potential coverage questions

Equipment replacement costs:

Properly maintained extinguishers last 12-15 years. Neglected equipment fails sooner, requiring premature replacement at $150-400 per unit.

ROI calculation:

$10,000 annual compliance program vs. $30,000+ violation exposure = clear financial justification even before considering actual fire protection value

—

PRACTICAL RECOMMENDATIONS

For School Districts Specifically

Leverage education sector resources:

State fire marshal offices often provide guidance specifically for educational facilities. Many states have school safety coordinators who can advise on fire equipment compliance programs.

State school facility organizations share best practices among districts. Other districts’ compliance approaches provide models and vendor references.

Insurance pools and consortiums serving educational institutions may have preferred fire safety vendors or compliance programs.

—

For Any Multi-Location Organization

Key success factors:

Start with accurate assessment:

Assumptions about current compliance status are usually optimistic. Professional assessment reveals reality.

Budget realistically:

Initial catch-up costs are real. Accurate budgeting prevents surprise shortfalls during implementation.

Prioritize unified provider:

Fragmented vendors create fragmented documentation. Single provider maintains continuous records and clear accountability.

Invest in digital tracking:

Manual systems fail at scale. Technology investment pays through reduced administrative burden and compliance assurance.

Plan for sustainability:

One-time corrections without systematic ongoing program just delay next compliance crisis. Build programs that maintain compliance automatically.

—

WORKING WITH PROFESSIONAL SERVICE PROVIDERS

What to Look For

NFPA certification:

Technicians should hold proper fire extinguisher service certification

Multi-location experience:

Provider should demonstrate experience with distributed facility management, not just single-site service

Digital platform capabilities:

Ask about tracking systems, reporting, mobile access for distributed stakeholders

References from similar organizations:

Talk to other school districts or multi-site organizations using their service

Clear service level agreements:

Written commitments about inspection frequencies, response times, documentation standards

Transparent pricing:

Understand exactly what’s included, what costs extra, how pricing adjusts with facility changes

—

Questions to Ask Potential Providers

“How do you track service deadlines across multiple buildings automatically?”

“What happens if we add or remove facilities during contract period?”

“How quickly can principals access documentation for their specific building?”

“What’s your process when inspection reveals equipment needing immediate service?”

“How do you handle hydrostatic testing coordination during school breaks?”

“Can you provide example compliance dashboard and reports?”

“What’s your average client retention rate for multi-location accounts?”

48Fire and other professional providers should answer these questions clearly with specific examples from current educational or multi-location clients.

—

GETTING STARTED

Step 1: Request Professional Assessment

Contact qualified fire equipment service provider for comprehensive assessment across all facilities.

What to provide for assessment:

- List of building locations

- Approximate equipment quantities (if known)

- Any existing service documentation

- Recent inspection reports (if available)

- Timeline for compliance needs

What assessment should deliver:

- Accurate equipment inventory

- Current compliance status

- Specific deficiency identification

- Prioritized correction plan

- Realistic cost estimates

Investment: $800-2,000 typically

Timeline: 2-4 weeks

[Request Assessment from 48Fire](/contact-us)

—

Step 2: Develop Implementation Plan

Work with provider and internal stakeholders to create realistic implementation approach.

Key planning elements:

- Correction timeline aligning with budget cycles

- Service schedule coordinating with academic calendars

- Communication plan for building administrators

- Documentation system setup

- Training for facility staff

—

Step 3: Secure Budget Authorization

Present clear proposal to decision-makers with:

- Assessment findings showing current status

- Specific costs for corrections and ongoing program

- Compliance requirements and violation risks

- Implementation timeline

- Expected outcomes

—

Step 4: Execute Corrections and Program Launch

Systematically bring equipment to compliance while establishing ongoing program:

- Critical safety issues first

- Overdue maintenance systematically addressed

- Digital tracking implemented

- Regular service schedule established

- Staff trained on procedures

—

Step 5: Maintain and Monitor

Ensure program operates as designed:

- Regular compliance reporting reviewed

- Service quality verified periodically

- Budget planning for future needs

- Adjustments made as facilities change

—

CONCLUSION

Multi-location fire equipment compliance requires systematic approach because organizational complexity makes ad-hoc management impractical.

The challenges are real:

- Distributed facilities with independent operations

- Personnel turnover erasing institutional knowledge

- Budget pressures creating deferred maintenance

- Vendor rotation fragmenting documentation

- Manual tracking overwhelming at scale

The solutions are proven:

- Comprehensive baseline assessment

- Unified professional service provider

- Digital tracking and automated scheduling

- Systematic inspection and maintenance programs

- Clear accountability and documentation

The investment is justified:

NFPA compliance costs $15-30 per extinguisher annually. Non-compliance costs $16,000+ per serious violation plus equipment failures during actual emergencies.

The outcome is sustainable:

Properly implemented systematic programs maintain continuous compliance with minimal ongoing administrative burden—exactly what multi-location organizations need.

Educational facilities nationwide demonstrate these approaches work. The same principles apply to any organization managing fire equipment across multiple buildings.

48Fire specializes in multi-location fire equipment compliance because we understand distributed facilities require different approaches than single-site management—unified service, centralized documentation, automated coordination, and consistent quality across all locations.

Fire equipment compliance at scale isn’t about checking boxes. It’s about building systems that work automatically, maintain continuously, and provide genuine protection across every building you operate.

[Begin Your Multi-Location Compliance Program](/contact-us)

—

48Fire

Multi-Location Fire Equipment Service

Educational Facilities • Commercial Operations • Distributed Portfolios

Contact: [/contact-us](/contact-us)

Proven: Systematic compliance programs serving organizations with 10-100+ locations nationwide