From Code Violations to Compliance: A Sprinkler System Case Study

Violation notice received: March 15, 2024

Compliance deadline: 90 days

Penalties for non-compliance: $500/day fines, potential occupancy revocation

Building at risk: 85,000 SF commercial property with 340 occupants

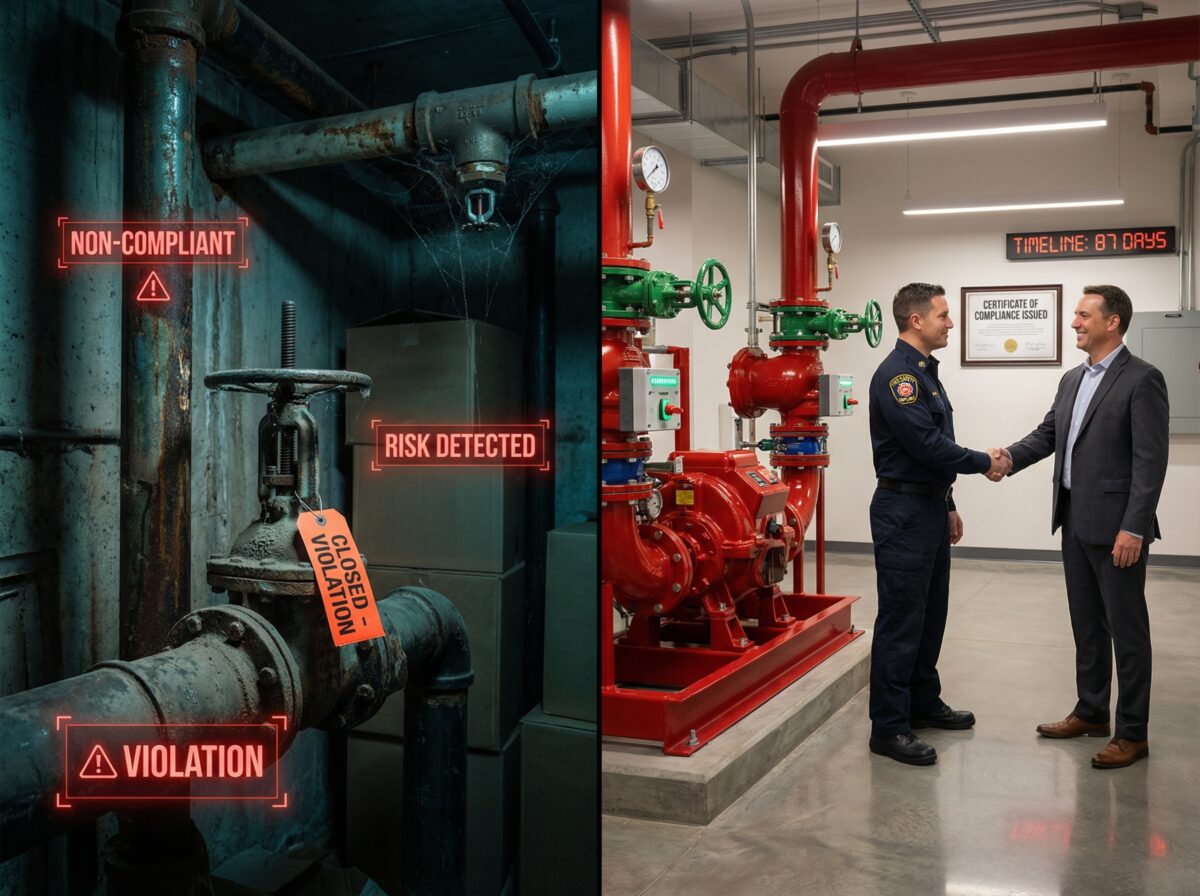

When the fire marshal’s inspection revealed 23 code violations in a supposedly compliant sprinkler system, the building owner faced a choice: massive fines and potential closure, or comprehensive remediation within 90 days.

48Fire delivered compliance in 87 days.

—

The Violations That Triggered Everything

What Started as Routine Became Critical

The building—a mixed-use commercial property built in 1998—had passed previous fire inspections without major issues. But a change in ownership triggered a comprehensive fire marshal review using updated code standards.

The results: 23 documented violations ranging from minor labeling issues to critical system deficiencies that compromised fire protection.

—

Violation Category 1: System Design Deficiencies (8 Violations)

V-1: Inadequate Sprinkler Density in Storage Areas

Code requirement: NFPA 13 requires 0.30 gpm/sf for high-hazard storage

Actual installation: 0.20 gpm/sf (ordinary hazard density)

Risk: Insufficient water delivery during fires in high-density storage zones

Why it happened: Building converted portion of warehouse to high-rack storage in 2019. Sprinkler system never upgraded to match increased fire load.

Remediation required: Add 47 sprinkler heads in storage areas, upgrade pipe sizing to deliver increased flow, recalculate hydraulics verifying adequate supply.

—

V-2: Exceeded 90% Water Supply Design Limit

Code requirement: NFPA 13 limits system design to 90% of available water supply

Actual design: 97% of available supply

Risk: System may fail to deliver adequate pressure during actual fires when conditions differ from design assumptions

Why it happened: Original 1998 design pushed limits. Municipal water pressure declined 8 PSI over 25 years as area developed.

Remediation required: Install fire pump boosting available pressure, allowing system to operate within 90% threshold.

—

V-3-V-8: Additional Design Issues

- Incorrect head spacing in corridors (exceeds maximum 130 SF coverage)

- Missing ESFR heads in high-rack areas (control mode inadequate)

- Inadequate pipe support spacing (exceeds NFPA 13 Table 9.3.5.4.1)

- Obstructed heads from suspended equipment installations

- Missing auxiliary drains in low points of dry pipe system

- Improper dry pipe system pitch (insufficient for drainage)

Pattern: Multiple violations resulted from building modifications over 26 years without corresponding sprinkler system updates.

—

Violation Category 2: Control and Valve Issues (6 Violations)

V-9: Control Valves Not Supervised

Code requirement: NFPA 13 requires tamper switches on all control valves reporting to fire alarm panel

Actual condition: 4 of 7 control valves lack supervision

Risk: Valves could be closed without detection, rendering system inoperative

Why it happened: Building added control valves during 2015 renovation. Electrician never connected tamper switches to alarm panel.

Remediation required: Install tamper switches on 4 unsupervised valves, wire to fire alarm panel, verify alarm transmission to monitoring station.

—

V-10: Inaccessible Control Valves

Code requirement: Control valves must be accessible for operation

Actual condition: 2 valves behind locked doors, 1 valve above ceiling requiring ladder

Risk: Emergency shutoff impossible during pipe breaks or head damage

Why it happened: Storage rooms built around valve locations. Drop ceiling installed after sprinkler system.

Remediation required: Relocate 2 valves to accessible locations, install access panel for ceiling valve with proper signage.

—

V-11-V-14: Additional Control/Valve Violations

- Missing valve identification signs (unable to determine which valve controls which area)

- OS&Y valve stems not indicating open position clearly

- Backflow preventer test report expired (over 1 year old)

- Missing drain and test connections on 3 branch lines

—

Violation Category 3: Fire Alarm Integration (4 Violations)

V-15: Flow Switches Not Connected to Fire Alarm

Code requirement: NFPA 13 and NFPA 72 require sprinkler flow switches connected to fire alarm system

Actual condition: 3 of 6 flow switches not wired to panel

Risk: Sprinkler activation doesn’t trigger building alarm or notify monitoring station

Why it happened: Electrician installed fire alarm system separate from sprinkler contractor. Integration never verified.

Remediation required: Wire 3 flow switches to alarm panel, program panel to display correct zones, test alarm transmission.

—

V-16-V-18: Additional Integration Violations

- Tamper switch signals not supervised (show trouble but don’t alarm)

- Fire alarm doesn’t shut down HVAC upon sprinkler activation (smoke spreads)

- No monitoring station notification verification (signals don’t transmit)

—

Violation Category 4: Documentation and Maintenance (5 Violations)

V-19: Missing ITM Records

Code requirement: NFPA 25 requires documented inspection, testing, and maintenance records

Actual condition: No records for previous 3 years

Risk: Cannot prove system maintained per requirements, insurance coverage questionable

Why it happened: Building owner changed maintenance contractors in 2021. New contractor performed work but didn’t provide documentation.

Remediation required: Implement comprehensive ITM program with documented procedures, establish record-keeping system, catch up on deferred testing.

—

V-20-V-23: Additional Documentation Violations

- Missing hydraulic calculation sheets (can’t verify design adequacy)

- No as-built drawings showing actual installation

- Expired fire pump test report (annual test not performed)

- Missing manufacturer specifications for installed equipment

—

The 87-Day Compliance Plan

48Fire developed phased remediation plan completing all corrections within the 90-day deadline.

Phase 1 (Days 1-30): Critical Safety Issues

Priority: Address violations creating immediate life safety risks

Week 1-2: Control Valve Supervision

- Install tamper switches on 4 unsupervised valves

- Wire to fire alarm panel

- Program alarm sequences

- Test supervision functionality

- Cost: $8,400 | Status: Completed Day 12

Week 2-3: Flow Switch Integration

- Wire 3 unconnected flow switches to alarm panel

- Program alarm zones

- Test signal transmission to monitoring station

- Verify HVAC shutdown integration

- Cost: $6,200 | Status: Completed Day 18

Week 3-4: Valve Accessibility

- Relocate 2 inaccessible valves

- Install access panel for ceiling valve

- Add proper signage

- Cost: $4,800 | Status: Completed Day 25

Phase 1 Total: $19,400 | Completed: Day 28

—

Phase 2 (Days 31-60): System Design Corrections

Priority: Address design deficiencies affecting system performance

Week 5-6: Fire Pump Installation

- Install fire pump boosting system capacity

- Wire controls and backup power

- Commission and test

- Update hydraulic calculations showing 90% compliance

- Cost: $68,000 | Status: Completed Day 42

Week 6-8: Storage Area Upgrades

- Add 47 sprinkler heads in high-density storage

- Upgrade pipe sizing for increased flow

- Install proper ESFR heads where required

- Recalculate hydraulics

- Cost: $52,000 | Status: Completed Day 56

Week 8-9: System Support and Drainage

- Add pipe supports meeting spacing requirements

- Install auxiliary drains in dry system low points

- Adjust dry pipe pitch for proper drainage

- Cost: $14,200 | Status: Completed Day 60

Phase 2 Total: $134,200 | Completed: Day 60

—

Phase 3 (Days 61-87): Documentation and Finalization

Priority: Complete documentation proving compliance

Week 9-10: Testing and Commissioning

- Perform hydrostatic pressure testing

- Conduct flow testing verifying adequate delivery

- Test all integration points

- Document all test results

- Cost: $8,600 | Status: Completed Day 68

Week 10-11: Documentation Assembly

- Create as-built drawings showing all modifications

- Compile hydraulic calculations with engineer’s seal

- Assemble equipment specifications

- Organize ITM records and establish ongoing schedule

- Generate compliance report addressing each violation

- Cost: $12,400 | Status: Completed Day 75

Week 11-12: Fire Marshal Re-Inspection Prep

- Internal inspection verifying all corrections

- Photograph all modifications

- Prepare presentation materials

- Conduct walkthrough with building owner

- Cost: $4,200 | Status: Completed Day 82

Phase 3 Total: $25,200 | Completed: Day 82

—

The Fire Marshal Re-Inspection

Scheduled: Day 87 (3 days before deadline)

Duration: 6 hours

Inspector: Same fire marshal who issued original violations

Inspection Sequence

Hour 1: Documentation Review

Fire marshal reviewed comprehensive compliance package:

- Response to each of 23 violations

- As-built drawings showing modifications

- Updated hydraulic calculations

- Test reports with measured data

- Equipment specifications

- ITM records and schedules

Finding: Documentation complete and professionally organized. All violations addressed on paper.

—

Hour 2-4: Physical Installation Verification

Fire marshal walked entire facility verifying:

✓ Control valve supervision functional (tested tamper switches)

✓ Flow switch integration operational (triggered test alarms)

✓ Valves accessible with proper signage

✓ Storage area head count and spacing

✓ Fire pump installation and commissioning

✓ Pipe support spacing

✓ Auxiliary drains present and functional

✓ Backflow preventer test current

Finding: Physical installation matches documentation. All corrections properly implemented.

—

Hour 4-5: System Performance Testing

Fire marshal witnessed:

- Flow test at most remote head (verified adequate pressure and flow)

- Fire pump automatic start test (verified proper operation)

- Alarm integration test (verified signals transmit correctly)

- HVAC shutdown sequence (verified air handlers stop)

- Tamper switch activation (verified alarm generation)

Finding: System performs as designed. All integration points function correctly.

—

Hour 5-6: Final Review and Determination

Fire marshal reviewed findings with building owner and 48Fire project manager.

Final determination: All 23 violations corrected. System now complies with current NFPA 13, NFPA 25, and NFPA 72 requirements.

Certificate of Compliance issued: Day 87

[Talk to an Expert!](/contact-us)

—

The Financial Impact

Total Remediation Cost

| Phase | Cost | Duration |

|---|---|---|

| Phase 1: Critical Safety | $19,400 | 28 days |

| Phase 2: System Design | $134,200 | 32 days |

| Phase 3: Documentation | $25,200 | 22 days |

| Total | $178,800 | 87 days |

Avoided Costs

Daily fine for non-compliance: $500/day

If remediation extended past deadline:

- Days 91-180 (90 days late): $45,000 in fines

- Potential occupancy revocation: Business interruption incalculable

- Legal costs defending violations: $25,000-$50,000

Insurance implications:

- Without compliance, insurance carrier threatened coverage termination

- Loss of insurance = breach of lease agreements with tenants

- Potential tenant departures and lease break penalties

Total avoided costs: $70,000-$120,000 minimum (excluding business interruption)

Long-Term Value

Insurance premium reduction: 15% ($18,200 annually) for upgraded systems and compliance documentation

Property value increase: Compliant systems with current documentation increase marketability

Tenant retention: Building maintains occupancy without disruption

—

Lessons from the Compliance Process

Lesson 1: Building Modifications Require System Updates

The building underwent three significant modifications (2015 renovation, 2019 storage conversion, 2021 office expansion). None included sprinkler system evaluations.

The pattern: Changes that increase fire load or occupancy require system verification. Failing to update fire protection creates accumulating code violations.

Best practice: Engage fire protection engineers during planning phase of any building modification. Determine whether changes affect fire protection requirements before construction begins.

—

Lesson 2: Documentation Gaps Create Compliance Uncertainty

Missing ITM records, lost hydraulic calculations, and absent as-built drawings made proving compliance impossible—even if systems were maintained.

The pattern: Work performed but not documented = work that can’t be proven. Fire marshals require evidence, not assurances.

Best practice: Establish documentation systems from day one. Maintain complete records for system lifetime. When changing contractors, ensure documentation transfers.

—

Lesson 3: Integration Failures Go Unnoticed Until Inspection

Flow switches and tamper switches installed but not connected. Fire alarm and HVAC systems not coordinated. These integration failures existed for years without detection.

The pattern: Multiple contractors install components without verifying integration. Systems appear complete but don’t function as intended.

Best practice: Require integration testing as part of every installation. Test complete sequences—not just individual components. Document integration functionality.

—

Lesson 4: Proactive Compliance Costs Less Than Reactive Remediation

If violations had been identified and corrected incrementally over 26 years, total cost would have been $80,000-$100,000 spread across decades. Correcting everything under deadline pressure cost $178,800 in 87 days.

The pattern: Deferred maintenance and skipped updates compound. Eventually triggering forced remediation at higher cost.

Best practice: Annual fire protection system reviews identifying code changes and building modifications. Address issues gradually rather than waiting for violation notices.

—

How to Avoid This Scenario

Conduct Annual Compliance Audits

Don’t wait for fire marshal inspections to reveal problems. Annual compliance audits by qualified fire protection professionals identify issues before they become violations.

Audit components:

- Review building modifications since last audit

- Verify system design still matches occupancy and fire load

- Check integration functionality

- Confirm documentation current and complete

- Test system performance

- Identify code changes affecting facility

Cost: $3,000-$8,000 annually

Value: Early identification enabling gradual corrections rather than emergency remediation

—

Establish Comprehensive ITM Programs

NFPA 25 compliance prevents many common violations. Regular inspection, testing, and maintenance keeps systems functional and documentation current.

Program elements:

- Scheduled inspections per NFPA 25 requirements

- Testing with documented results

- Maintenance addressing identified deficiencies

- Record-keeping proving compliance

- Annual review and planning

Cost: $8,000-$15,000 annually for commercial properties

Value: Continuous compliance, insurance premium reductions, avoided violations

—

Engage Fire Protection Engineers for Modifications

Any building modification should trigger fire protection review:

- Occupancy changes

- Storage configuration changes

- Equipment installations affecting head clearances

- Structural modifications

- HVAC system changes

Engineer evaluation determines: Does modification affect fire protection requirements? Are system upgrades needed? How to maintain code compliance?

Cost: $2,000-$5,000 per modification review

Value: Prevents accumulating violations from unremediated changes

—

Maintain Complete Documentation

Establish documentation system from initial installation:

- Original design documents and approvals

- As-built drawings

- Hydraulic calculations

- Equipment specifications

- All test reports

- Maintenance records

- Modification history

Update documentation: Whenever systems modified, ensure as-builts updated and calculations revised

Cost: Administrative time only

Value: Ability to prove compliance during inspections

—

When Fire Marshal Inspections Reveal Violations

Understand the Timeline

Violation notices typically include compliance deadlines:

- Minor violations: 30-60 days

- Major violations: 60-90 days

- Critical life safety: Immediate action required

Don’t ignore deadlines. Fire marshals have authority to:

- Issue daily fines

- Revoke certificates of occupancy

- Order building evacuations

- Refer cases for legal action

—

Engage Professional Help Immediately

Fire protection contractors experienced with code compliance can:

- Assess violations accurately

- Develop remediation plans

- Provide cost and timeline estimates

- Coordinate with fire marshal’s office

- Complete work meeting code requirements

- Document compliance

Attempting DIY remediation risks:

- Incorrect solutions

- Additional violations from improper work

- Missed deadlines

- Failed re-inspections

—

Communicate Proactively with Fire Marshal

Fire marshals want compliance—not penalties. Proactive communication demonstrates good faith:

- Acknowledge violations immediately

- Present remediation plan with timeline

- Request clarification on ambiguous items

- Provide progress updates

- Invite interim inspections

Most fire marshals will: Grant reasonable timeline extensions if progress demonstrated, provide guidance on proper remediation, work collaboratively toward compliance

—

Prioritize Life Safety Issues

If violations include immediate life safety concerns:

- Address these first

- Implement temporary measures if permanent fixes require time

- Document actions taken

- Communicate status to fire marshal

Example temporary measures:

- Fire watch during system impairments

- Temporary barricades limiting occupancy in affected areas

- Posted warnings and alternative procedures

—

48Fire’s Code Compliance Services

We specialize in bringing non-compliant facilities into full code compliance—on time and on budget.

Our process:

Violation Assessment: Review fire marshal citations, identify root causes, evaluate building conditions, determine remediation requirements

Code compliance plan: Phased approach prioritizing life safety, detailed scope of work, accurate cost estimates, realistic timeline

Professional remediation: Licensed contractors performing all work, quality verification throughout, complete testing and documentation, coordination with fire marshal’s office

Compliance verification: Pre-inspection internal review, comprehensive documentation package, support during fire marshal re-inspection, certificate of compliance achievement

Results: Zero failed re-inspections across compliance projects, average completion 5% faster than deadline, comprehensive documentation preventing future violations

—

Key Takeaways

Code violations in existing fire protection systems typically result from building modifications without system updates, missing documentation despite performed maintenance, integration failures between systems, and deferred compliance creating accumulating issues.

This case study demonstrated complete remediation of 23 violations in 87 days through phased approach: critical safety issues first (28 days, $19,400), system design corrections (32 days, $134,200), and documentation completion (22 days, $25,200) for total cost of $178,800.

Proactive compliance through annual audits ($3,000-$8,000), comprehensive ITM programs ($8,000-$15,000 annually), and fire protection engineer involvement in modifications ($2,000-$5,000 per review) prevents expensive emergency remediation.

Fire marshal re-inspection verified all violations corrected through 6-hour inspection reviewing documentation, verifying physical installation, and witnessing system performance testing before issuing certificate of compliance.

Ready to bring your fire protection systems into full code compliance?

[Talk to an Expert!](/contact-us)

—