What Inspectors Look for During Lighting Certification

—

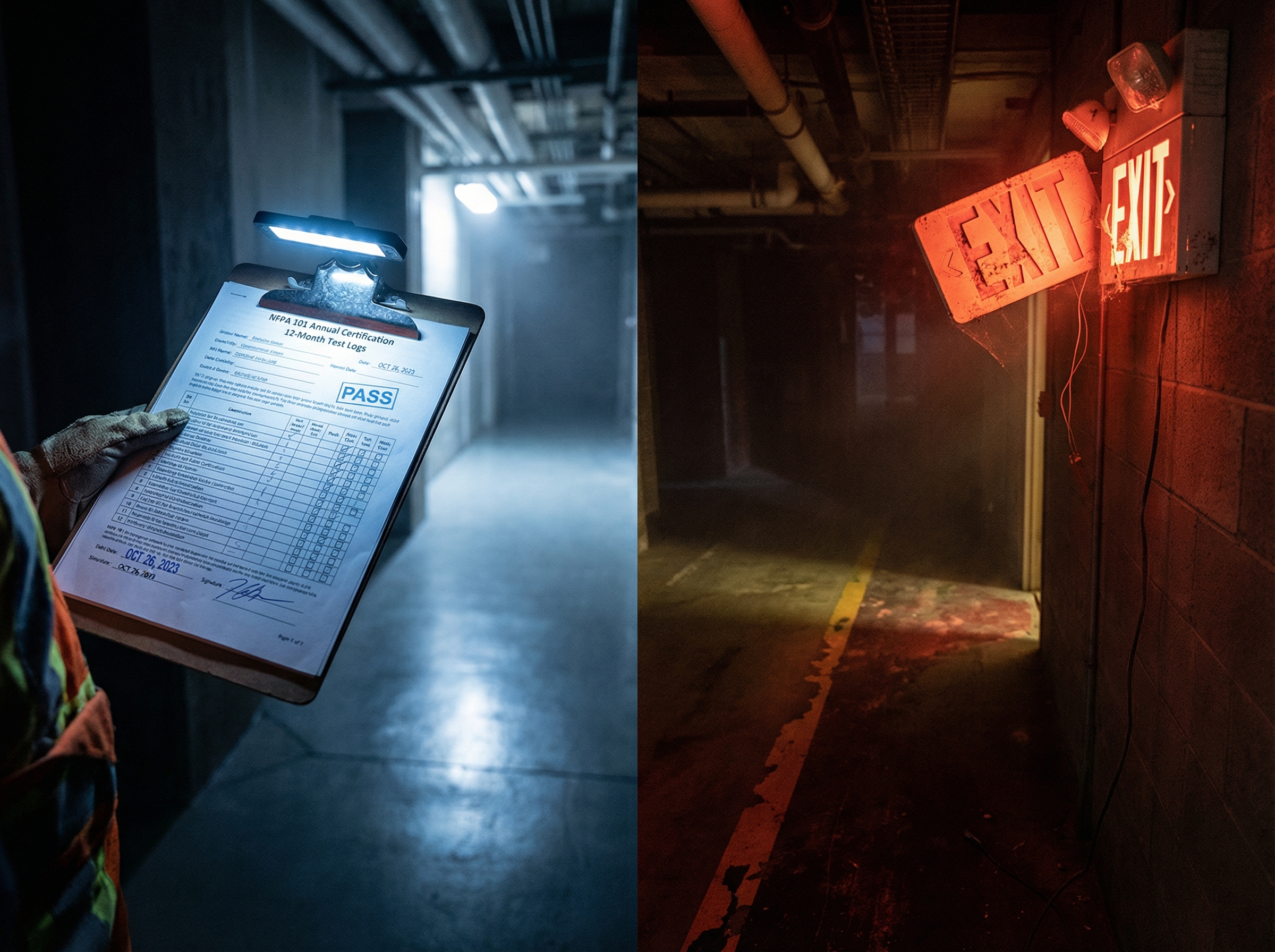

THE FIRE MARSHAL INSPECTION FRAMEWORK

Emergency lighting certification = Systematic verification of 8 critical compliance elements

“`

FIRE MARSHAL INSPECTION STRUCTURE:

DOCUMENTATION REVIEW (Pre-physical inspection):

├─ Monthly test logs (12 months complete?)

├─ Annual test certificates (current year present?)

├─ Service provider credentials (qualified personnel?)

├─ Deficiency correction records (issues resolved?)

└─ Equipment inventory (system documentation current?)

PHYSICAL SYSTEM INSPECTION (Visual assessment):

├─ Exit sign visibility (proper placement, illumination?)

├─ Emergency light presence (adequate coverage?)

├─ Equipment condition (physical damage, mounting?)

├─ Green running man symbol (current code standard?)

└─ Obstruction assessment (clear access, visibility?)

FUNCTIONAL TESTING (Performance verification):

├─ Sample unit testing (random activation checks)

├─ Brightness assessment (adequate illumination?)

├─ Duration capability (battery capacity adequate?)

├─ Automatic activation (transfer switch functional?)

└─ System reliability (overall performance confidence)

COMPLIANCE DETERMINATION (Pass/fail decision):

├─ Documentation complete? (records adequate)

├─ System functional? (testing passed)

├─ Code compliance? (current standards met)

└─ RESULT: Certificate issued OR violations cited

“`

Understanding fire marshal inspection criteria enables proactive preparation ensuring successful certification.

This article documents the 8 elements fire marshals systematically verify during emergency lighting certification inspections.

48Fire fire marshal inspection preparation services ensure facilities meet all certification criteria through comprehensive pre-inspection verification.

—

INSPECTION ELEMENT 1 → DOCUMENTATION COMPLETENESS

What Fire Marshals Review First

Before examining physical systems, inspectors verify paperwork compliance

—

Monthly Test Logs (12-Month Requirement)

WHAT FIRE MARSHALS LOOK FOR:

“`

MONTHLY TESTING DOCUMENTATION CHECKLIST:

COMPLETENESS VERIFICATION:

☐ All 12 months present (January through December)

☐ No gaps or missing months (consistent testing)

☐ Each month dated (specific test dates)

☐ Inspector identified (name or initials)

☐ All units tested (complete facility coverage)

CONTENT ADEQUACY:

☐ Individual unit results (pass/fail each unit)

☐ Deficiencies noted (specific problems identified)

☐ Corrective actions documented (repairs performed)

☐ Correction dates recorded (timeline to resolution)

☐ Re-testing documented (verification of repairs)

FORMAT ACCEPTABILITY:

☐ Paper logs: Legible, organized, complete

☐ Digital logs: Accessible, printable, comprehensive

☐ Either format acceptable (content matters most)

“`

Common violations fire marshals cite:

| Violation | Description | Severity |

|---|---|---|

| Missing months | Gaps in monthly testing | Serious |

| No documentation | No logs available at all | Critical |

| Incomplete records | Some units tested, others omitted | Moderate |

| No deficiency follow-up | Problems noted but not corrected | Serious |

| Illegible logs | Handwriting unreadable | Minor to moderate |

Fire marshal expectation:

Complete 12-month documentation immediately available when requested during fire marshal inspection.

48Fire monthly testing services provide professional documentation satisfying fire marshal inspection requirements.

—

Annual Test Certificates

CERTIFICATION DOCUMENTATION REQUIREMENTS:

“`

FIRE MARSHAL ANNUAL CERTIFICATE VERIFICATION:

REQUIRED CERTIFICATE ELEMENTS:

☐ Current year certificate (within last 12 months)

☐ Facility identification (property name, address)

☐ Complete unit inventory (all tested units listed)

☐ Individual test results (pass/fail each unit)

☐ 90-minute duration verification (NFPA 101 requirement met)

☐ Testing date (when performed)

☐ Service provider identification (company name)

☐ Technician credentials (license, certification)

☐ Professional signature (qualified personnel)

☐ Next test due date (future compliance planning)

CERTIFICATE VALIDITY:

├─ Must be from qualified service provider

├─ Cannot be self-certification (professional required)

├─ Must document actual testing (not estimated)

└─ Must include deficiency corrections

“`

What disqualifies a certificate during fire marshal inspection:

- Older than 12 months (expired)

- Self-prepared by facility staff (not professional)

- Missing critical elements (incomplete)

- Unsigned or lacking credentials (not authenticated)

- Deficiencies noted but not corrected (unresolved issues)

48Fire annual certification provides fire marshal inspection-compliant professional certificates with complete documentation.

—

Service Provider Credentials

QUALIFIED PERSONNEL VERIFICATION:

Fire marshals verify service provider qualifications:

“`

ACCEPTABLE CREDENTIALS:

☐ Licensed electrical contractor (state license)

☐ Fire protection contractor certification

☐ Manufacturer training certificates (equipment-specific)

☐ Company insurance documentation (liability coverage)

☐ Technician individual certifications (when required)

CREDENTIAL DOCUMENTATION:

├─ Service provider business license

├─ Insurance certificates (current)

├─ Technician qualifications (on file)

└─ Training documentation (when applicable)

“`

Why fire marshals check credentials:

Ensures testing performed by personnel competent to accurately assess emergency lighting system performance and compliance.

48Fire maintains current credentials readily available for fire marshal inspection verification.

—

INSPECTION ELEMENT 2 → EXIT SIGN COMPLIANCE

Visibility and Placement Verification

Fire marshals systematically assess exit sign adequacy

—

Proper Placement Standards

WHAT FIRE MARSHALS VERIFY:

“`

EXIT SIGN LOCATION REQUIREMENTS:

MANDATORY EXIT SIGN LOCATIONS:

☐ Every exit door (doors leading to outside or exit discharge)

☐ Decision points (corridor intersections, T-junctions)

☐ Change of direction (where egress path turns)

☐ Stair access (doors leading to exit stairs)

☐ Directional indicators (arrows pointing to exits when not visible)

VISIBILITY REQUIREMENTS:

☐ 100-foot maximum distance (no point in corridor >100′ from visible sign)

☐ Clear line of sight (no obstructions blocking view)

☐ Adequate height (typically 6-7 feet minimum above floor)

☐ Proper orientation (readable from approach directions)

☐ Illuminated continuously (or designed to illuminate on power failure)

COVERAGE GAPS FIRE MARSHALS IDENTIFY:

├─ Exits unmarked (violation)

├─ Visibility blocked (stored materials, decorations)

├─ Insufficient directional signs (occupants cannot navigate)

└─ Excessive spacing (>100 feet between visible signs)

“`

Fire marshal inspection process:

- Walks facility following egress paths

- Verifies exit sign visibility from all required locations

- Measures distances if adequacy questionable

- Notes missing or inadequate signage

—

Green Running Man Symbol Standard

CURRENT CODE COMPLIANCE:

“`

FIRE MARSHAL ASSESSMENT:

NEW CONSTRUCTION/RENOVATION:

├─ Green running man pictogram REQUIRED

├─ Text-only “EXIT” signs NON-COMPLIANT

├─ International ISO 7010 standard

└─ Universal recognition objective

EXISTING BUILDINGS:

├─ Text-only “EXIT” signs ACCEPTABLE (grandfathered)

├─ No forced replacement mandate

├─ Voluntary upgrades encouraged

└─ Required when renovations trigger code compliance

FIRE MARSHAL VERIFICATION:

☐ Appropriate symbol for building status (new vs. existing)

☐ Signs visible and functional

☐ Green color present (not faded to white/yellow)

☐ Running man orientation correct (directional)

“`

What triggers green running man requirement:

- New construction permits

- Change of occupancy permits

- Substantial renovations (typically >50% area affected)

- Fire marshal discretion (local enforcement variations)

48Fire exit sign upgrades ensure fire marshal inspection compliance with current standards when required.

—

INSPECTION ELEMENT 3 → EMERGENCY LIGHT COVERAGE

Illumination Adequacy Assessment

Fire marshals verify sufficient emergency lighting along egress paths

—

Coverage Requirements

WHAT FIRE MARSHALS CHECK:

“`

EMERGENCY LIGHTING COVERAGE VERIFICATION:

REQUIRED ILLUMINATION LOCATIONS:

☐ Corridors and hallways (entire egress route)

☐ Stairwells (every landing, stairs visible)

☐ Exit doorways (doors easily located)

☐ Lobbies and common areas (navigation possible)

☐ Changes in elevation (steps, ramps visible)

ADEQUACY INDICATORS:

☐ No dark zones (entire path visible)

☐ Overlapping coverage (multiple units illuminate areas)

☐ Obstacles visible (furniture, equipment identifiable)

☐ Exit hardware visible (door handles, panic bars clear)

☐ Consistent illumination (no dramatic bright/dark variations)

FIRE MARSHAL ASSESSMENT METHOD:

├─ Visual walk-through (following egress paths)

├─ Darkness simulation (if possible, lights turned off)

├─ Professional judgment (experience-based assessment)

└─ Light meter (rare, only if adequacy questioned)

“`

NFPA 101 illumination standard:

One lux (0.1 footcandle) minimum at floor level along egress path center line.

Fire marshal inspection emphasis:

More concerned with obvious gaps than precise measurements. Complete darkness in egress paths = violation regardless of measurement.

—

Unit Quantity and Placement

SYSTEMATIC COVERAGE:

“`

FIRE MARSHAL EVALUATION:

ADEQUATE UNIT DENSITY:

├─ Emergency lights spaced appropriately (typically 30-50 feet)

├─ No excessively long dark sections (coverage maintained)

├─ High-occupancy areas (additional units for crowd navigation)

└─ Complex layouts (adequate guidance through maze-like spaces)

STRATEGIC PLACEMENT:

├─ Mounted at effective height (8-12 feet typical)

├─ Aimed appropriately (illuminating egress path, not ceilings)

├─ Obstruction-free (furniture/equipment not blocking)

└─ Secure mounting (units not loose or sagging)

VIOLATIONS FIRE MARSHALS CITE:

├─ Insufficient units (dark zones present)

├─ Poor placement (lights aimed wrong direction)

├─ Obstructed units (boxes, equipment blocking)

└─ Missing units (removed and not replaced)

“`

48Fire coverage assessment services verify adequate emergency lighting placement meeting fire marshal inspection standards.

—

INSPECTION ELEMENT 4 → EQUIPMENT CONDITION

Physical Integrity Verification

Fire marshals assess emergency lighting physical condition

—

Housing and Lens Condition

WHAT FIRE MARSHALS EXAMINE:

“`

PHYSICAL CONDITION CHECKLIST:

ACCEPTABLE CONDITION:

☐ Housing intact (no cracks, breaks)

☐ Lens clear (not yellowed, cracked, broken)

☐ Sign face legible (symbols/text visible)

☐ No discoloration (fading, UV damage)

☐ Clean appearance (excessive dirt/dust noted)

VIOLATIONS DURING FIRE MARSHAL INSPECTION:

├─ Broken housing (internal components exposed)

├─ Missing lens (no protection, reduced visibility)

├─ Cracked lens (moisture intrusion risk)

├─ Sign face illegible (faded, damaged)

└─ Severe deterioration (beyond cosmetic)

SEVERITY ASSESSMENT:

├─ Minor cosmetic issues: Noted but not typically cited

├─ Functional impact: Cited as violation (repair required)

├─ Safety hazard: Critical violation (immediate correction)

└─ Life safety compromise: Possible occupancy restriction

“`

—

Mounting Security

STRUCTURAL INTEGRITY:

“`

FIRE MARSHAL MOUNTING VERIFICATION:

SECURE MOUNTING:

☐ Units firmly attached (no movement when touched)

☐ Mounting hardware present (not missing screws/bolts)

☐ Proper orientation (level, aligned correctly)

☐ No sagging (pendant units hanging straight)

☐ Wall/ceiling attachment solid (not pulling away)

MOUNTING VIOLATIONS:

├─ Loose units (risk of falling)

├─ Missing mounting hardware (inadequate attachment)

├─ Improper installation (ceiling tiles, not structure)

├─ Sagging/tilted units (poor installation)

└─ Completely fallen units (critical safety issue)

FIRE MARSHAL CONCERN:

Units falling = injury risk + loss of emergency lighting + code violation

“`

48Fire physical condition assessment identifies mounting and housing issues before fire marshal inspection.

—

INSPECTION ELEMENT 5 → FUNCTIONAL PERFORMANCE

Operational Testing During Inspection

Fire marshals perform selective functional testing

—

Sample Unit Testing

FIRE MARSHAL TESTING PROTOCOL:

“`

RANDOM SAMPLING APPROACH:

TYPICAL FIRE MARSHAL METHOD:

├─ Selects 5-10% of units randomly (not all units tested)

├─ Varies locations (different areas of building)

├─ Tests functionality (activation and brightness)

└─ Determines overall confidence (sample represents system)

TESTING PROCEDURE:

1. Presses test button (simulates power failure)

2. Observes immediate activation (transfer switch function)

3. Assesses brightness (adequate illumination subjectively)

4. Allows 30-60 second operation (brief duration check)

5. Verifies return to normal (AC power restoration)

SAMPLE TEST RESULTS:

├─ All sampled units pass: System confidence HIGH (certification likely)

├─ 1-2 units fail: Moderate concern (may cite specific units)

├─ 3+ units fail: System reliability questioned (comprehensive testing ordered)

└─ Majority fail: Critical compliance issue (certificate denied)

“`

Why fire marshals sample test:

- Time constraints (full testing takes hours)

- Professional judgment (sample indicates overall status)

- Annual certification verification (assumes recent comprehensive testing)

Risk of failed sample testing:

If fire marshal random sampling reveals failures, may order comprehensive testing of all units before certification possible.

—

Brightness Assessment

ILLUMINATION ADEQUACY:

“`

FIRE MARSHAL BRIGHTNESS EVALUATION:

SUBJECTIVE ASSESSMENT (Most common):

├─ Does light illuminate effectively? (professional judgment)

├─ Can egress path be seen? (visibility adequate)

├─ Are obstacles identifiable? (safety sufficient)

└─ Is brightness consistent? (no dramatic dimming)

OBJECTIVE MEASUREMENT (Rare):

├─ Light meter used (if adequacy questioned)

├─ One lux minimum verified (NFPA 101 standard)

├─ Multiple measurement points (along egress path)

└─ Documentation of readings (evidence for citations)

DIM ILLUMINATION CONCERNS:

├─ Battery degradation (reduced capacity)

├─ LED/lamp aging (output declining)

├─ Incorrect aiming (light not reaching floor)

└─ Inadequate unit quantity (insufficient coverage)

“`

What fire marshals consider dim:

If inspector questions whether illumination adequate for safe egress, unit considered inadequate regardless of technical measurement.

—

INSPECTION ELEMENT 6 → IMMEDIATE DEFICIENCY CORRECTION

Unresolved Issues from Previous Testing

Fire marshals verify problems were corrected

—

Correction Documentation Review

WHAT FIRE MARSHALS VERIFY:

“`

DEFICIENCY RESOLUTION CHECKLIST:

FROM MONTHLY TESTING:

☐ Failures noted in monthly logs CORRECTED? (verification required)

☐ Correction dates documented? (timeline to resolution)

☐ Re-testing performed? (repairs verified functional)

☐ Open issues resolved? (no outstanding problems)

FROM PREVIOUS ANNUAL TESTING:

☐ Failed units from last year REPLACED/REPAIRED? (status change)

☐ Certificate deficiency notes ADDRESSED? (recommendations completed)

☐ Follow-up corrections COMPLETED? (issues not deferred)

FIRE MARSHAL INQUIRY:

“I see Unit 23 failed in March. Show me the correction record.”

├─ Acceptable response: Documentation showing repair in April + re-test pass

├─ Violation: “We haven’t fixed that yet” (unresolved deficiency)

└─ Result: Citation for inadequate maintenance if not corrected

“`

NFPA requirement:

Defective equipment shall be replaced or repaired immediately (not deferred).

—

Pre-Inspection Corrections

STRATEGIC PREPARATION:

“`

SMART FACILITY APPROACH:

2-4 WEEKS BEFORE FIRE MARSHAL INSPECTION:

├─ Comprehensive pre-inspection testing (48Fire professional assessment)

├─ All deficiencies identified and corrected BEFORE inspector arrives

├─ Documentation updated (reflects current compliant status)

└─ Confidence high (no surprises during inspection)

REACTIVE FACILITY MISTAKE:

├─ No pre-inspection preparation

├─ Fire marshal testing reveals failures

├─ Emergency corrections required (rushed, expensive)

├─ Possible re-inspection needed (delays certification)

└─ Citations issued (penalties, professional reputation impact)

“`

48Fire pre-inspection services identify and correct all deficiencies before fire marshal inspection ensuring successful certification.

—

INSPECTION ELEMENT 7 → CODE COMPLIANCE VERIFICATION

Current Standards Assessment

Fire marshals verify system meets applicable codes

—

NFPA 101 Requirements

LIFE SAFETY CODE VERIFICATION:

“`

FIRE MARSHAL NFPA 101 CHECKLIST:

MONTHLY TESTING COMPLIANCE:

☐ Performed at 30-day intervals? (12 per year minimum)

☐ Documented properly? (records adequate)

ANNUAL TESTING COMPLIANCE:

☐ 90-minute duration test performed? (full capacity verified)

☐ Within last 12 months? (current certification)

☐ Professional testing? (qualified personnel)

PERFORMANCE STANDARDS:

☐ One lux minimum illumination? (NFPA 101 requirement)

☐ 90-minute duration capability? (battery capacity adequate)

☐ Automatic activation? (transfer switch functional)

SYSTEM DESIGN:

☐ Exit signs at required locations? (proper placement)

☐ Emergency lighting adequate coverage? (no dark zones)

☐ Green running man symbol (if required by building status)

“`

—

Local Code Variations

AHJ SPECIFIC REQUIREMENTS:

“`

FIRE MARSHAL DISCRETION:

STANDARD NFPA 101 REQUIREMENTS:

├─ Apply universally (baseline compliance)

├─ Minimum standards (cannot be less restrictive)

└─ Nationally recognized (consistent interpretation)

LOCAL AMENDMENTS POSSIBLE:

├─ More frequent testing (some jurisdictions quarterly)

├─ Enhanced documentation (additional records)

├─ Specific technologies (LED mandates in some areas)

└─ Stricter standards (more restrictive than NFPA)

FIRE MARSHAL EXPECTATION:

Facility must meet whichever is more restrictive:

├─ NFPA 101 baseline, OR

├─ Local jurisdiction amendments

└─ Inspector enforces applicable local code

“`

48Fire maintains current knowledge of local fire marshal inspection requirements and code amendments.

—

INSPECTION ELEMENT 8 → OVERALL SYSTEM RELIABILITY

Confidence Assessment

Fire marshals make holistic reliability judgment

—

System Health Indicators

WHAT BUILDS FIRE MARSHAL CONFIDENCE:

“`

POSITIVE INDICATORS:

DOCUMENTATION:

├─ Complete 12-month records (no gaps)

├─ Professional annual certification (qualified service)

├─ Prompt deficiency correction (responsible maintenance)

└─ Organized presentation (easy retrieval)

PHYSICAL SYSTEM:

├─ Modern technology (LED equipment)

├─ Good physical condition (well-maintained)

├─ Adequate coverage (no obvious gaps)

└─ Secure mounting (proper installation)

TESTING PERFORMANCE:

├─ Sampled units all pass (reliable operation)

├─ Good brightness (adequate illumination)

├─ Immediate activation (functional transfer)

└─ Consistent performance (system-wide reliability)

OVERALL IMPRESSION:

├─ Professional maintenance (48Fire service evident)

├─ Proactive approach (not reactive scrambling)

├─ Code knowledge demonstrated (facility competent)

└─ Life safety priority clear (compliance culture)

RESULT: Fire marshal confident system reliable → Certification issued

“`

—

Red Flags Raising Concerns

WHAT WORRIES FIRE MARSHALS:

“`

NEGATIVE INDICATORS:

DOCUMENTATION ISSUES:

├─ Missing months (testing inconsistent)

├─ No annual certification (compliance unknown)

├─ Open deficiencies (problems unresolved)

└─ Disorganized records (management inadequate)

PHYSICAL CONDITIONS:

├─ Old technology (incandescent, outdated)

├─ Poor condition (damage, neglect visible)

├─ Obvious gaps (insufficient coverage)

└─ Loose units (maintenance lacking)

TESTING FAILURES:

├─ Multiple units fail (system unreliable)

├─ Dim illumination (inadequate performance)

├─ Delayed activation (transfer issues)

└─ Inconsistent results (unpredictable system)

OVERALL IMPRESSION:

├─ Reactive maintenance (crisis-driven)

├─ Limited code knowledge (compliance questionable)

├─ Life safety not prioritized (budget/convenience over safety)

└─ Fire marshal confidence: LOW

RESULT: Violations cited → Corrections required → Re-inspection necessary

“`

—

FIRE MARSHAL INSPECTION PREPARATION CHECKLIST

Pre-Inspection Readiness Protocol

48Fire systematic preparation:

—

30 Days Before Inspection

“`

☐ Comprehensive system testing (all units verified functional)

☐ Deficiency identification (problems documented)

☐ Immediate corrections (critical issues resolved)

☐ Documentation review (12 months complete?)

☐ Annual certificate current? (within last 12 months)

☐ Service provider credentials on file (48Fire documentation)

“`

—

7 Days Before Inspection

“`

☐ Physical condition walk-through (damage, mounting assessed)

☐ Exit sign visibility verified (placement adequate)

☐ Coverage assessment (no dark zones)

☐ Final testing sample (random units checked)

☐ Documentation organized (instant retrieval prepared)

☐ Facility contact designated (inspection day coordinator)

“`

—

Inspection Day

“`

☐ Documentation immediately accessible (laptop/folder ready)

☐ Facility contact available (answer questions, provide access)

☐ Respectful cooperation (professional demeanor)

☐ Notes taken (inspector comments documented)

☐ Follow-up confirmed (if corrections needed)

☐ Certificate received (successful inspection) OR correction plan agreed

“`

48Fire fire marshal inspection preparation ensures facilities meet all 8 certification elements through systematic pre-inspection verification and correction.

—

CONCLUSION

Eight Elements Fire Marshals Verify During Emergency Lighting Certification

Element 1: Documentation Completeness

- Monthly test logs (12 months complete, no gaps)

- Annual test certificates (current year, professional)

- Service provider credentials (qualified personnel verified)

- Deficiency correction records (issues resolved)

Element 2: Exit Sign Compliance

- Proper placement (exits marked, 100-foot visibility rule)

- Green running man symbol (when required by code)

- Visibility unobstructed (clear line of sight)

- Illumination functional (signs lit or designed to activate)

Element 3: Emergency Light Coverage

- Adequate unit quantity (no dark zones in egress paths)

- Strategic placement (proper aiming, effective illumination)

- One lux minimum at floor level (NFPA 101 standard)

- Overlapping coverage (comprehensive illumination)

Element 4: Equipment Condition

- Housing integrity (no cracks, damage)

- Lens clarity (not broken, yellowed, dirty)

- Mounting security (firmly attached, proper orientation)

- Physical appearance (professional maintenance evident)

Element 5: Functional Performance

- Sample unit testing (5-10% randomly selected)

- Immediate activation (automatic transfer functional)

- Adequate brightness (subjective or measured)

- Consistent operation (reliability demonstrated)

Element 6: Immediate Deficiency Correction

- Previous failures resolved (monthly log issues corrected)

- Annual certificate recommendations addressed (follow-up complete)

- No open issues (current compliance maintained)

- Prompt correction timeline (immediate per NFPA)

Element 7: Code Compliance Verification

- NFPA 101 requirements met (monthly, annual, performance)

- Local code amendments satisfied (AHJ-specific rules)

- Current standards application (modern requirements)

- Professional testing documented (qualified service provider)

Element 8: Overall System Reliability

- Documentation quality (organized, complete, professional)

- Physical system condition (well-maintained, modern)

- Testing performance (sample units pass)

- Fire marshal confidence (holistic positive impression)

Fire marshal inspection outcome:

- All 8 elements satisfied: Certification issued (successful inspection)

- Deficiencies identified: Violations cited + correction orders + re-inspection required

- Critical failures: Possible occupancy restrictions (severe cases)

Preparation advantage:

Facilities conducting 48Fire pre-inspection verification 2-4 weeks advance identify and correct all deficiencies before fire marshal inspection ensuring successful first-time certification.

48Fire fire marshal inspection services provide complete emergency lighting certification preparation through comprehensive pre-inspection testing identifying all potential deficiencies, immediate correction of identified issues ensuring compliant status, documentation organization providing instant retrieval during inspection, professional service provider credentials readily available for verification, equipment condition assessment addressing mounting and physical concerns, coverage adequacy verification confirming illumination standards, functional performance testing validating operational reliability, and ongoing maintenance programs maintaining continuous compliance—transforming fire marshal inspection from stressful uncertain event to confident successful certification through systematic preparation addressing all 8 verification elements inspectors systematically assess.

[Ensure Fire Marshal Inspection Success](/contact-us)

—

48Fire

Fire Marshal Inspection Preparation Services

Pre-Inspection Testing • Deficiency Correction • Certification Support

Contact: [/contact-us](/contact-us)