How One Facility Passed Its Lighting Test on First Try

—

THE FIRST-TRY SUCCESS FRAMEWORK

Emergency exit lighting testing success requires strategic preparation, not luck.

Most facilities approach testing reactively—scheduling when convenient, hoping equipment passes, scrambling when failures occur.

First-try success facilities approach differently:

“`

REACTIVE APPROACH (Common)

Overdue testing scheduled

↓

Equipment status unknown

↓

Testing reveals failures

↓

Emergency corrections needed

↓

Re-testing required

↓

Time and cost doubled

PROACTIVE APPROACH (First-Try Success)

Systematic maintenance year-round

↓

Pre-test verification performed

↓

Known issues corrected proactively

↓

Professional testing scheduled

↓

First-try pass achieved

↓

Certification immediate

“`

This article documents systematic emergency exit lighting preparation enabling first-attempt testing success.

—

SUCCESS ELEMENT 1 → PRE-TEST BASELINE ASSESSMENT

Know Your System Before Testing

60 days before scheduled professional testing:

—

Complete Equipment Inventory Verification

INVENTORY CONFIRMATION CHECKLIST:

“`

☐ All emergency exit lighting units identified and documented

☐ Location of each unit mapped accurately

☐ Equipment types recorded (maintained/non-maintained/combined)

☐ Installation dates documented

☐ Battery types and ages verified

☐ Last service date confirmed for each unit

☐ Known issues cataloged

☐ Replacement units identified if needed

“`

Why inventory matters:

- Testing schedule based on unit quantity

- Budget estimation accurate

- No surprises during professional service

- Equipment ordering time if replacements needed

48Fire pre-test assessment includes complete emergency exit lighting inventory verification ensuring no equipment overlooked during testing.

—

Historical Performance Review

PAST TESTING ANALYSIS:

| Previous Test Element | Review Focus | Action Items |

|---|---|---|

| Units that failed | Identify repeat offenders | Priority inspection/replacement |

| Marginal performers | Units barely passing 90 minutes | Preemptive battery replacement |

| New installations | Never professionally tested | Verify proper installation |

| Modified areas | Building changes since last test | Coverage reassessment |

Pattern identification:

- Specific locations with recurring issues

- Battery types with shorter lifespans

- Environmental factors affecting performance

- Maintenance quality assessment

48Fire historical analysis reviews previous test results identifying risk areas requiring attention before upcoming testing.

—

Environmental Assessment

PERFORMANCE-AFFECTING CONDITIONS:

Temperature extremes:

□ Basement units in unconditioned spaces

□ Attic installations with extreme heat

□ Outdoor units exposed to weather

□ Equipment near heating/cooling sources

Impact: Battery lifespan reduced, charging efficiency affected

Moisture exposure:

□ Humid environments (kitchens, restrooms)

□ Areas with potential water intrusion

□ Locations near plumbing

Impact: Corrosion, electrical issues, premature failure

Vibration sources:

□ Near mechanical equipment

□ High-traffic areas with constant impact

□ Locations with structural vibration

Impact: Connection loosening, mounting degradation, component failure

Mitigation actions:

- Protective enclosures where appropriate

- Enhanced maintenance frequency in harsh environments

- Proactive replacement before testing in high-risk locations

—

SUCCESS ELEMENT 2 → SYSTEMATIC MONTHLY VERIFICATION

Building Testing Confidence Through Consistency

30-60 days before professional testing:

—

Enhanced Monthly Testing Protocol

STANDARD vs. ENHANCED MONTHLY TESTING:

Standard monthly (30 seconds):

- Basic function verification

- Illumination confirmation

- Quick pass/fail determination

Enhanced pre-test monthly:

- Extended duration test (2-3 minutes)

- Brightness assessment throughout

- Battery response observation

- Early warning sign detection

Early warning indicators:

“`

CONCERNING SIGNS DURING MONTHLY TESTS:

Immediate Issues:

├─ No illumination when activated

├─ Flickering during test

├─ Very dim output

└─ Complete failure

Marginal Performance:

├─ Brightness declining during 30-second test

├─ Delayed activation

├─ Reduced light output vs. previous months

└─ Battery getting warm during brief test

ACTION: Immediate attention required before annual test

“`

48Fire enhanced monthly verification 45-60 days before annual testing identifies marginal performers requiring correction preventing test-day failures.

—

Documentation Completeness Verification

MONTHLY LOG REVIEW CHECKLIST:

“`

☐ All 12 months documented (no gaps)

☐ Inspector identification consistent

☐ Each unit tested every month

☐ Pass/fail results clear

☐ Deficiencies noted specifically

☐ Corrective actions documented

☐ Follow-up verification recorded

☐ Log organized for auditor review

“`

Documentation gaps requiring correction:

- Missing months (test immediately, document retroactively with explanation)

- Incomplete inspector identification (add going forward)

- Vague deficiency notes (specify issues clearly)

- No corrective action documentation (document all repairs)

First-try success correlation:

Complete monthly documentation demonstrates systematic maintenance, favorably influencing professional test approach and auditor perception.

—

SUCCESS ELEMENT 3 → PROACTIVE DEFICIENCY CORRECTION

Fix Known Issues Before Testing

30-45 days before professional testing:

—

Battery Replacement Priority Assessment

PROACTIVE BATTERY REPLACEMENT CRITERIA:

| Battery Condition | Age | Monthly Test Performance | Replacement Decision |

|---|---|---|---|

| Lead-acid battery | 4+ years | Any concerns | Replace before test |

| Lead-acid battery | 3.5-4 years | Marginal performance | Replace before test |

| Nickel-cadmium | 8+ years | Any concerns | Replace before test |

| Nickel-cadmium | 7-8 years | Marginal performance | Replace before test |

| Lithium | 12+ years | Any concerns | Replace before test |

| Any battery type | Any age | Consistent monthly failures | Replace immediately |

Replacement economics:

“`

SCENARIO 1: Wait for test to reveal failure

Test fee: $150-300

Fails at 45 minutes → Battery replacement required

Return visit: $150-250

Total: $300-550 + delay

SCENARIO 2: Proactive replacement before test

Battery replacement: $75-150

Test proceeds: First visit

Passes: Immediate certification

Total: $75-150 (one visit)

SAVINGS: $225-400 + time saved

“`

48Fire pre-test battery assessment identifies replacement candidates with proactive service preventing test-day failures and re-testing costs.

—

Lamp and LED Replacement

ILLUMINATION SOURCE VERIFICATION:

Traditional lamp assessment:

□ Brightness diminished compared to new

□ Blackening visible on bulb

□ Age exceeds typical lifespan (check hours)

□ Filament condition questionable

LED assessment:

□ Brightness reduced (gradual degradation)

□ Color temperature changed

□ Individual LEDs dark

□ Driver components showing stress

Pre-test replacement strategy:

Replace any questionable lamps/LEDs rather than risking failure during 90-minute test when dimming becomes apparent.

Cost consideration:

Lamp replacement: $5-25 per unit

Test failure and correction: $150-300 additional

Decision: Replace questionable lamps proactively.

—

Charging Circuit Verification

PRE-TEST CHARGING ASSESSMENT:

Check indicators:

□ Float voltage within specifications (typically 13.6-13.8V for 12V systems)

□ Charging current adequate

□ Battery fully charged (verify voltage after 24+ hours on charge)

□ No unusual heat at charging components

Testing method:

Disconnect AC power briefly, verify battery voltage, reconnect, verify charging resumes.

Concerning findings:

- Voltage outside specification range

- No charging current when battery discharged

- Battery warm/hot during charging

- Voltage not recovering after discharge

Correction before test:

PC board adjustment or replacement, connection cleaning/tightening, power supply verification.

48Fire pre-test charging verification ensures batteries receive proper charge preventing test failures from charging system defects.

—

SUCCESS ELEMENT 4 → STRATEGIC TEST SCHEDULING

Timing Optimization for Success

Planning considerations:

—

Seasonal Timing

OPTIMAL TESTING PERIODS:

Preferred seasons:

“`

SPRING (March-May)

✓ Moderate temperatures (battery performance optimal)

✓ Stable weather (lower power outage risk during recharge)

✓ Good natural lighting (safety during testing)

FALL (September-November)

✓ Moderate temperatures

✓ Stable weather

✓ Before holiday season complications

“`

Challenging seasons:

“`

SUMMER (June-August)

⚠ Extreme heat (battery stress)

⚠ Storm season (power outage risk)

⚠ Vacation schedules (coordination difficulty)

WINTER (December-February)

⚠ Extreme cold (battery performance reduced)

⚠ Storm season (power outage risk)

⚠ Holiday closures (scheduling limitations)

“`

Temperature impact on testing:

| Ambient Temperature | Battery Performance | Test Reliability |

|---|---|---|

| 20°C / 68°F (optimal) | 100% capacity | Highest |

| 0°C / 32°F | 80% capacity | Reduced |

| -20°C / -4°F | 50% capacity | Significantly reduced |

| 40°C / 104°F | 80% capacity | Heat stress risk |

Recommendation: Schedule emergency exit lighting testing during moderate temperature periods for optimal battery performance.

—

Occupancy Coordination

TESTING SCHEDULE OPTIMIZATION:

Consider building occupancy patterns:

Low-occupancy periods:

✓ Weekends (if building closed)

✓ Holiday periods

✓ Slow business seasons

✓ After-hours scheduling

Advantage: Reduced disruption, easier access, safer during vulnerability period

High-occupancy periods:

✗ Peak business times

✗ Special events

✗ Critical operations periods

✗ Emergency drills scheduled

Coordination requirements:

“`

3-4 WEEKS BEFORE TEST:

☐ Confirm testing date with 48Fire

☐ Reserve building access/keys

☐ Notify building occupants

☐ Coordinate with security/facilities

☐ Schedule around critical operations

☐ Plan for 24-48 hour recharge vulnerability

“`

—

Testing Sequence Planning

SYSTEMATIC TEST EXECUTION:

Facility with multiple zones:

“`

ZONE 1: Administrative offices

├─ Test first (lowest risk area)

├─ Verify testing procedure

└─ Identify any systematic issues

ZONE 2: Common areas and corridors

├─ Test during low-traffic periods

├─ Coordinate with occupant movement

└─ Stage temporary lighting if needed

ZONE 3: Critical operations

├─ Test last (after procedure refined)

├─ Coordinate with operations schedule

└─ Minimize disruption

ZONE 4: Emergency areas (stairwells, exits)

├─ Test carefully (life safety critical)

├─ Ensure backup measures available

└─ Document thoroughly

“`

48Fire professional scheduling coordinates emergency exit lighting testing sequences minimizing occupancy disruption while ensuring comprehensive coverage.

—

SUCCESS ELEMENT 5 → PROFESSIONAL SERVICE SELECTION

Certified Technician Importance

Why professional testing matters:

—

Qualification Verification

NFPA 101 REQUIREMENT:

Testing must be performed by trained persons with proper equipment.

Professional qualifications checklist:

“`

48FIRE TECHNICIAN CREDENTIALS:

☑ NFPA training certification documented

☑ Manufacturer-specific certifications (where applicable)

☑ Electronic load simulator equipment calibrated

☑ Testing procedures NFPA-compliant

☑ Professional liability insurance maintained

☑ Years of experience verifiable

☑ Customer references available

“`

vs. Unqualified service:

□ No formal training

□ Visual observation only (no load testing)

□ Improper test procedures

□ Inadequate documentation

□ Results questionable for compliance

First-try success factor:

Qualified technicians identify marginal conditions, perform complete procedures, provide defensible documentation.

—

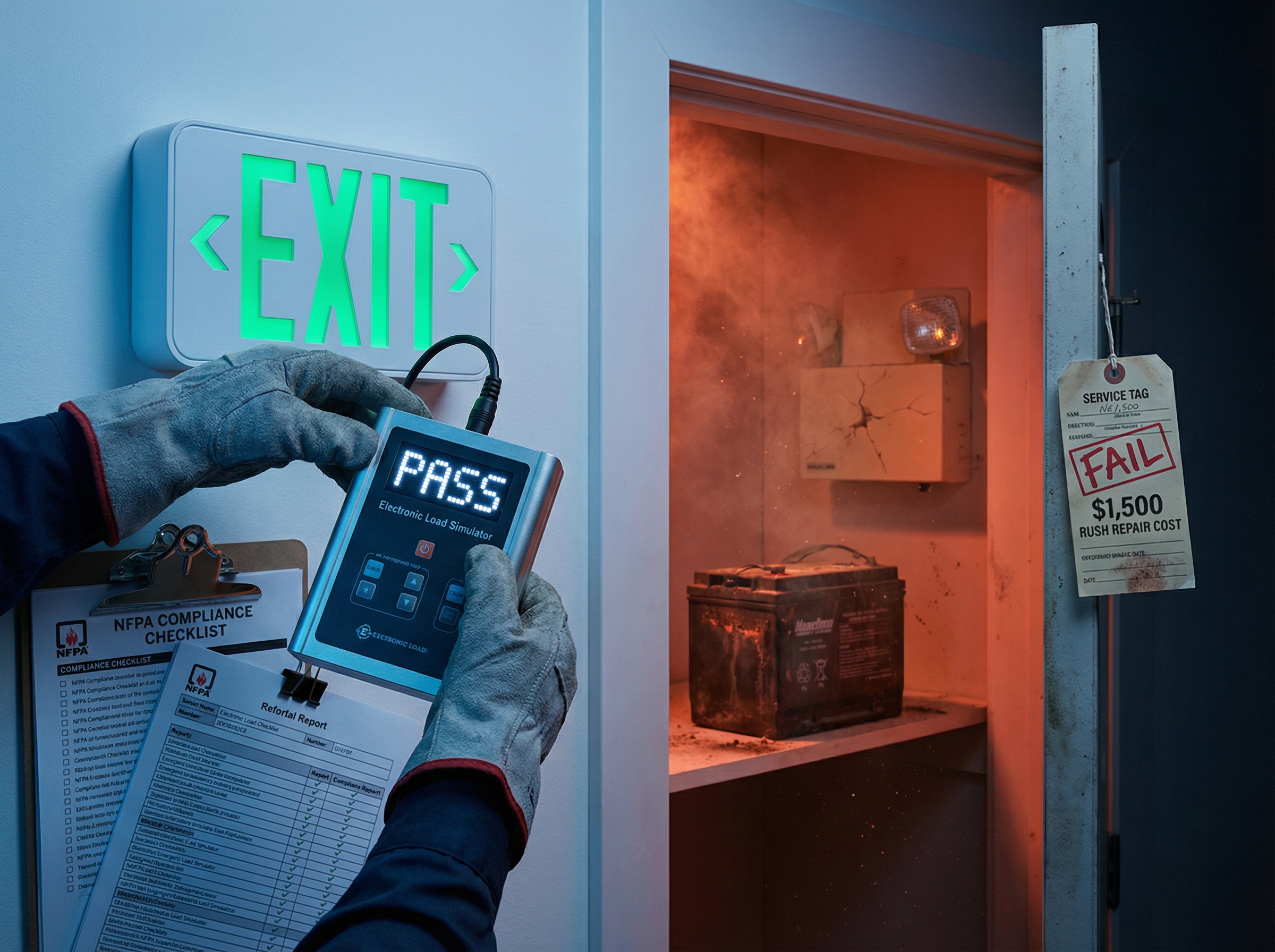

Equipment and Methodology

PROPER TESTING EQUIPMENT:

Electronic load simulator:

- Applies controlled load during testing

- Reveals true battery capacity

- Detects failures visual testing misses

- Required for NFPA compliance

Voltage and current measurement:

- Verifies charging circuit function

- Confirms proper float voltage

- Identifies electrical issues

- Supports PC board adjustment

Documentation tools:

- Digital recordkeeping

- Photographic evidence

- Certificate generation

- Audit-ready reports

48Fire professional testing equipment meets all NFPA requirements ensuring accurate results and defensible compliance documentation.

—

SUCCESS ELEMENT 6 → DAY-OF-TEST EXECUTION

Test Day Best Practices

Preparation checklist:

—

Final Pre-Test Verification

MORNING OF TEST (Before technician arrival):

“`

☐ Confirm all access arrangements (keys, codes, escorts)

☐ Notify security of testing activity

☐ Post temporary signage if needed

☐ Verify building occupancy coordination

☐ Stage documentation for technician review

☐ Identify any last-minute concerns

☐ Confirm emergency contact availability

☐ Prepare workspace for technician

“`

—

During Testing Coordination

FACILITY LIAISON RESPONSIBILITIES:

Access facilitation:

□ Unlock secured areas

□ Escort technician as needed

□ Coordinate elevator use

□ Manage building occupant questions

Documentation support:

□ Provide historical test records

□ Review findings as testing progresses

□ Authorize immediate corrections if minor issues found

□ Coordinate with management on major findings

Communication:

□ Answer technician questions about building

□ Clarify equipment locations

□ Explain any unusual conditions

□ Facilitate problem-solving

48Fire testing coordination includes facility liaison briefing ensuring smooth test execution and immediate issue resolution.

—

Real-Time Issue Management

ADDRESSING PROBLEMS DISCOVERED DURING TESTING:

Minor issues (immediate correction possible):

| Issue | Immediate Correction | Continue Testing |

|---|---|---|

| Dirty lens | Clean on-site | Yes |

| Loose connection | Tighten immediately | Yes |

| Lamp just failed | Replace if spare available | Yes |

| Mounting loose | Secure bracket | Yes |

Major issues (requiring follow-up):

| Issue | Immediate Action | Next Steps |

|---|---|---|

| Battery fails capacity | Document, continue testing others | Schedule battery replacement, re-test |

| Charging circuit problem | Note for repair | Coordinate repair, re-test affected units |

| Multiple unit failures | Complete inventory | Comprehensive system assessment |

First-try success principle:

Address correctable issues immediately during testing, schedule prompt correction for items requiring parts/repair.

—

SUCCESS ELEMENT 7 → POST-TEST DOCUMENTATION

Certificate and Record Management

Immediately after testing:

—

Comprehensive Documentation Receipt

REQUIRED DOCUMENTATION FROM 48FIRE:

“`

ANNUAL TEST CERTIFICATE

├─ Facility identification

├─ Test date and technician

├─ Complete equipment inventory tested

├─ 90-minute duration results (each unit)

├─ Battery load test data

├─ Charging circuit verification

├─ Float voltage adjustments made

├─ Deficiencies identified

├─ Corrective actions performed

├─ Units requiring follow-up

├─ Next test due date

└─ Certificate signature and company seal

PHOTOGRAPHIC DOCUMENTATION

├─ Equipment location verification

├─ Test in progress documentation

├─ Deficiency evidence

└─ Corrective action proof

DETAILED TEST REPORT

├─ Individual unit results

├─ Performance trends

├─ Recommendations

└─ Lifecycle projections

“`

—

Emergency Lighting File Update

IMMEDIATE ACTIONS AFTER TESTING:

“`

DAY 1 POST-TEST:

☐ File certificate in emergency lighting file

☐ Update equipment inventory with test results

☐ Schedule any required follow-up corrections

☐ Update maintenance calendar with next test due date

☐ Submit documentation to building owner/insurance

☐ Brief facilities team on findings

WEEK 1 POST-TEST:

☐ Perform any required corrections

☐ Obtain re-test for corrected units if needed

☐ Update documentation with correction evidence

☐ Verify all systems operational

☐ Close out any work orders

MONTH 1 POST-TEST:

☐ Resume monthly testing schedule

☐ Monitor any units noted as marginal

☐ Budget for recommendations from test report

☐ Plan any system upgrades identified

“`

48Fire digital documentation automatically updates emergency exit lighting files with test results, certificates, and recommendations maintaining complete compliance records.

—

SUCCESS MEASUREMENT

Quantifying First-Try Success Value

Comparative analysis:

—

Time Savings

FIRST-TRY SUCCESS:

“`

Pre-test preparation: 2-4 hours

Professional testing: 4-8 hours (depending on facility size)

Documentation receipt: Immediate

Certification: Same day

Total time: 1 day

“`

REACTIVE APPROACH WITH FAILURES:

“`

Initial testing: 4-8 hours

Failure identification: During test

Correction coordination: 1-2 weeks

Parts ordering/delivery: 3-7 days

Correction service: 2-4 hours

Re-testing: 4-8 hours

Documentation: After re-test

Certification: 2-4 weeks after initial test

Total time: 2-4 weeks

“`

Time saved with first-try success: 2-4 weeks

—

Cost Comparison

FIRST-TRY SUCCESS COSTS:

- Pre-test assessment: $200-400 (if needed)

- Proactive corrections: $300-800 (targeted replacements)

- Professional testing: $500-1,500 (facility size dependent)

- Total: $1,000-2,700

REACTIVE FAILURE COSTS:

- Professional testing: $500-1,500

- Test failures identified: Multiple units

- Emergency corrections: $800-2,000

- Return testing visit: $350-750

- Rush service premiums: 25-40% upcharge

- Extended downtime: Productivity impact

- Total: $2,000-5,000+

Cost savings with first-try success: $1,000-2,300+

—

Compliance Confidence

INTANGIBLE BENEFITS:

Stress reduction:

- No surprise failures

- Predictable process

- Confident audit readiness

- Management satisfaction

Operational continuity:

- No emergency disruptions

- Scheduled corrections

- Predictable compliance timeline

- Professional relationships maintained

Liability protection:

- Complete documentation

- Demonstrated due diligence

- Defensible compliance

- Insurance acceptance

—

IMPLEMENTATION ROADMAP

Building First-Try Success Capability

48Fire systematic approach:

—

90-Day Preparation Timeline

DAYS 90-60: Assessment Phase

□ Complete inventory verification

□ Historical performance review

□ Environmental assessment

□ Risk identification

□ Correction prioritization

DAYS 60-30: Correction Phase

□ Proactive battery replacements

□ Lamp/LED replacements

□ Charging circuit verification

□ Documentation gap closure

□ Enhanced monthly testing

DAYS 30-14: Finalization Phase

□ Final pre-test verification

□ Test scheduling coordination

□ Access arrangements confirmed

□ Liaison identified and briefed

□ Temporary measures staged

DAYS 14-1: Preparation Phase

□ Documentation organized

□ Building notifications sent

□ Final walkthrough completed

□ Any last-minute issues addressed

□ Test-day logistics confirmed

TEST DAY: Execution Phase

□ Professional testing performed

□ Issues managed real-time

□ Documentation received

□ Certification obtained

POST-TEST: Follow-up Phase

□ File updates completed

□ Follow-up corrections scheduled

□ System monitoring resumed

□ Next test planning initiated

—

CONCLUSION

First-Try Emergency Exit Lighting Testing Success

Success elements enabling first-attempt certification:

Pre-Test Baseline Assessment:

- Complete inventory verification

- Historical performance review

- Environmental assessment

- Risk identification

Systematic Monthly Verification:

- Enhanced testing 45-60 days before annual test

- Early warning sign detection

- Documentation completeness verification

Proactive Deficiency Correction:

- Battery replacement priority assessment

- Lamp/LED proactive replacement

- Charging circuit verification

- Cost-effective preventive approach

Strategic Test Scheduling:

- Seasonal timing optimization

- Occupancy coordination

- Testing sequence planning

- Vulnerability management

Professional Service Selection:

- Qualified technician credentials

- Proper testing equipment

- NFPA-compliant methodology

- 48Fire certified service

Day-of-Test Execution:

- Final pre-test verification

- Coordinated testing support

- Real-time issue management

- Immediate minor corrections

Post-Test Documentation:

- Comprehensive certificate receipt

- Emergency lighting file update

- Follow-up action coordination

- Compliance confidence

Measurable advantages:

- Time savings: 2-4 weeks vs. reactive approach

- Cost savings: $1,000-2,300+ vs. failure corrections

- Stress reduction: Predictable process

- Compliance confidence: Defensible documentation

48Fire emergency exit lighting testing services provide complete first-try success support through 90-day preparation timeline, proactive deficiency correction, professional certified testing, real-time issue management, comprehensive documentation, and follow-up coordination—ensuring emergency exit lighting systems pass testing on first attempt with immediate certification.

[Schedule First-Try Success Testing](/contact-us)

—

48Fire

Emergency Exit Lighting Testing Services

First-Try Success Preparation • Professional Certification • Complete Compliance

Contact: [/contact-us](/contact-us)