How We Reduced Inspection Time Across 300+ Locations

—

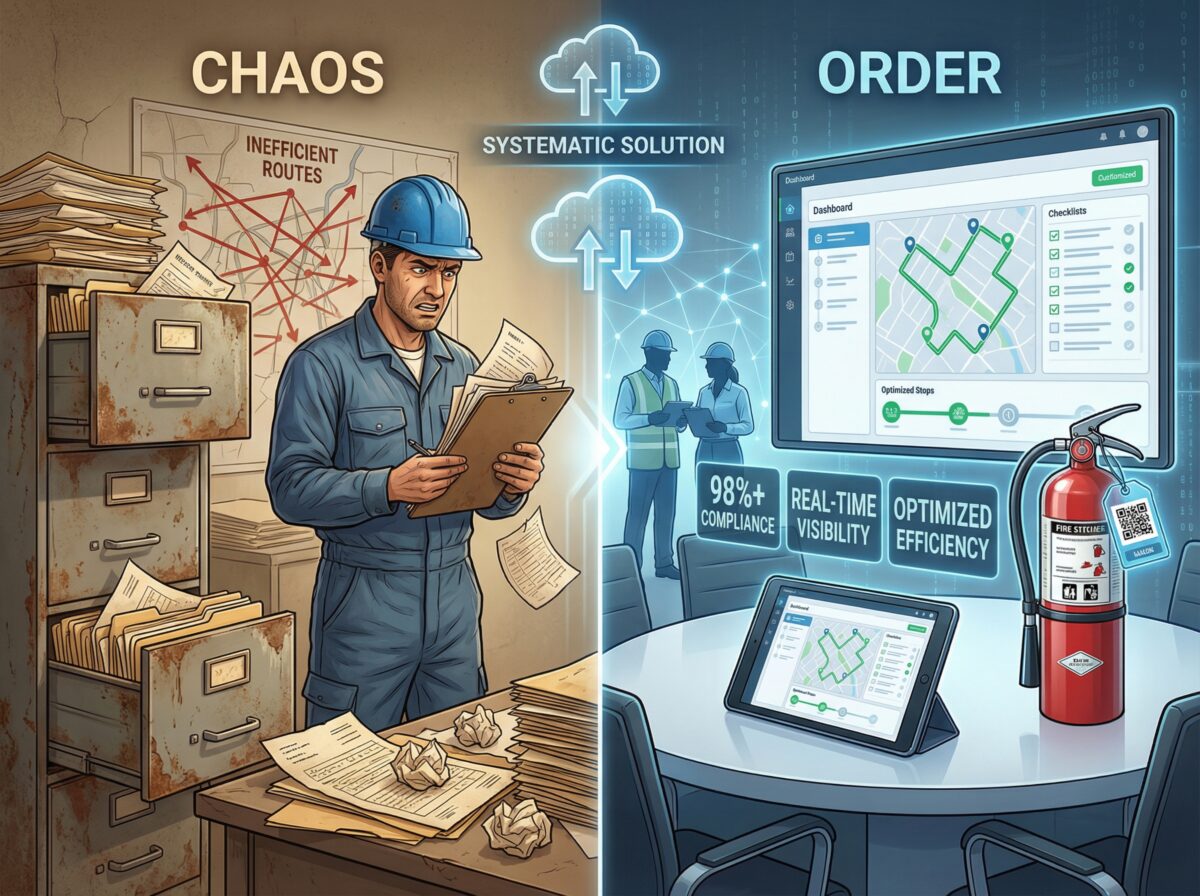

Picture this: Three hundred facilities scattered across twelve states. Each one legally required to have fire extinguishers inspected every thirty days. Different site managers. Different schedules. Different levels of cooperation. One massive compliance headache.

Sound familiar?

Multi-location fire safety creates a peculiar torture: the requirements are straightforward (monthly inspections, simple documentation), but execution becomes absurdly complicated at scale. What takes twenty minutes at one location somehow devours entire weeks when you multiply it across hundreds of properties.

Organizations typically respond by either throwing money at the problem (expensive service contracts, redundant visits) or accepting chronic non-compliance (fingers crossed until the fire marshal shows up).

There’s a third option. It involves treating fire extinguisher inspection as a system problem requiring systematic solutions rather than a procurement problem requiring more vendors.

Here’s how that transformation actually works—and why it matters more than you’d think for something as mundane as checking pressure gauges.

—

WHERE MOST ORGANIZATIONS START

Let’s talk about typical multi-location fire extinguisher inspection before anyone applies actual thought to the process.

The scheduling situation:

Someone at corporate (usually facilities, sometimes safety, occasionally whoever drew the short straw) maintains a spreadsheet listing all the properties. Monthly, they contact each location—phone calls, emails, texts—trying to schedule inspection visits. Site managers are busy. They don’t respond immediately. Follow-ups multiply. When someone finally commits to a date, it goes on multiple calendars using different systems.

Technicians receive lists of appointments. They plan routes based on whatever logic makes sense to them that day. Traffic happens. Sites aren’t ready. Locked doors. Missing contacts. Inspections get pushed to tomorrow, next week, whenever.

The inspection variability:

Technician A is thorough. Spends forty-five minutes per location, checks every extinguisher carefully, takes detailed notes. Technician B is efficient. Fifteen minutes in and out. Both locations get marked “inspected.” The reality of what actually got inspected? Nobody really knows.

Different checklists. Different documentation standards. Some technicians photograph everything. Others rely on memory. Consistency exists only in the fantasy that everyone’s doing it right.

The documentation catastrophe:

Paper forms go into filing cabinets at each site. Or they get lost. Or they’re incomplete. Or the handwriting is illegible. Or they’re sitting in a technician’s truck somewhere.

Six months later, when compliance needs to prove inspections happened, someone spends days calling around asking “do you have the paperwork from April?” Sometimes they find it. Often they don’t. Fire marshals love this game during audits.

The actual math:

Assume three hundred locations need monthly inspections. Twenty-five minutes average per inspection (fifteen-minute inspection plus ten minutes for documentation and coordination). Basic multiplication: 125 hours monthly just for inspections.

Add scheduling time. Add travel between locations. Add documentation processing. Add chasing missing paperwork. Add rescheduling when appointments fall through.

Real time investment? Somewhere north of 200 hours monthly. At typical service rates, that’s $12,000-20,000 monthly depending on market rates and whether you’re using internal staff or contractors.

For compliance activity that should be utterly routine.

—

THE SYSTEMATIC ALTERNATIVE

Professional fire extinguisher inspection services like 48Fire approach multi-location compliance differently—treating it as logistics and data management challenge rather than just fieldwork.

Automated coordination replaces phone tag:

Digital scheduling systems eliminate most human coordination. Sites load into platforms once with contact details and preferences. Software calculates inspection intervals automatically based on last service date (NFPA 10 requires minimum 30-day intervals). System generates schedules, sends automated notifications, tracks confirmations.

Site managers receive notifications forty-eight hours before scheduled visits. They confirm through simple click, no phone call required. Non-responses trigger alerts prompting follow-up only when necessary. Reschedules handle through same system with automatic cascade updates.

Coordination time drops dramatically. What consumed thirty hours monthly becomes four hours—mostly handling exceptions rather than managing normal flow.

Route optimization eliminates wasted travel:

Geographic clustering software groups locations logically. Instead of technicians bouncing around metro areas randomly, routes follow efficient patterns. North suburbs in one cluster. Downtown locations together. Industrial parks grouped.

Same coverage, dramatically less driving. Example: technician previously spent two hours driving to complete four inspections in a five-hour day. Optimized routing completes those same four inspections in three hours total. That 40% time savings multiplies across hundreds of monthly inspection visits.

Standardized protocols create consistency:

Every 48Fire technician follows identical inspection sequences regardless of location or individual preferences. Digital checklists on tablets ensure no steps get skipped. Barcode scanning identifies equipment positively (no guessing which extinguisher this is). Photo requirements enforce visual documentation standards.

Inspection time becomes predictable. Equipment issues get caught reliably rather than depending on which technician showed up that day. Documentation quality becomes uniform.

Real-time visibility replaces information scarcity:

Corporate compliance teams see inspection status across all locations through dashboards—not by making calls or hunting paperwork. Which sites completed this month? Which are scheduled? Where are gaps developing?

When fire marshals arrive for surprise inspections, complete documentation for that location pulls up in seconds. Photographs from last inspection. Technician certification. Service tags. Interval compliance verification. Audits transform from stressful scrambles into brief confirmations.

—

MEASURED OUTCOMES

Organizations implementing systematic fire extinguisher inspection services typically see:

Time efficiency improvements:

- Scheduling coordination: 80-90% reduction (automation handles routine communication)

- Travel time: 30-45% reduction (route optimization)

- Inspection execution: 30-40% reduction (standardized protocols, no wasted motion)

- Documentation processing: 90%+ reduction (digital capture eliminates paper chase)

Compliance improvements:

- Inspection interval adherence: from 80-85% typical to 98%+ (automated scheduling prevents gaps)

- Documentation completeness: from 70-80% typical to 99%+ (digital requirements enforce completion)

- Equipment issue detection: 25-40% increase (systematic inspection catches what rushed visits miss)

Operational benefits:

- Predictable site disruption (same day/time monthly vs. random calls)

- Instant audit readiness (no more document hunting)

- Faster issue resolution (problems identified during inspection often fixed same visit)

- Reduced emergency service calls (proactive detection prevents failures)

Numbers vary based on starting conditions. Organizations with reasonably good existing processes see smaller improvements. Those starting from chaotic manual systems see dramatic transformation.

—

CRITICAL COMPONENTS

Several elements make systematic multi-location inspection services work effectively.

Complete Equipment Inventory

You can’t inspect what you don’t know exists. First step: comprehensive equipment inventory across all locations.

Every fire extinguisher gets identified, barcoded, and catalogued with:

- Exact location (not “break room” but “break room north wall, 4 feet from door”)

- Equipment specifications (type, size, rating, manufacturer)

- Manufacturing date (determines service life and testing schedules)

- Last service date (establishes next inspection interval)

This front-end investment—typically 60-100 hours for organizations with several hundred locations—enables everything else. Without accurate inventory, even sophisticated software produces garbage results.

48Fire conducts thorough equipment inventory during program initiation, creating the foundation for systematic ongoing service.

Site Manager Engagement

Inspections happen at sites controlled by site managers. Their cooperation determines whether systematic approaches succeed or collapse.

Engagement requires demonstrating benefits:

- Predictability: Same day/time monthly beats random interruptions

- Reduced burden: Automated notifications beat phone tag

- Compliance protection: Complete documentation protects site from violations

- Immediate issue resolution: Problems get fixed during inspections, not through follow-up visits

Most site managers appreciate systematic approaches once they understand the alternative is continued chaos. Initial communication matters—explaining what’s changing and why prevents resistance.

Technician Consistency

Field technicians make or break inspection quality. They need:

- Training on protocols: Everyone follows identical procedures

- Proficiency with tools: Tablets, apps, barcode scanners must be second nature

- Decision-making authority: On-site issue resolution without calling office

- Quality standards: What constitutes acceptable documentation, inspection thoroughness

48Fire maintains certified technician training programs ensuring consistent service delivery regardless of which specific technician visits any particular location.

Continuous Measurement

What gets measured improves. Platforms track:

- Average inspection time per location

- Documentation completion rates

- Equipment issue detection frequency

- Interval compliance percentages

- Site manager satisfaction scores

Monthly reviews identify opportunities: Which locations consistently take longer? Where do scheduling conflicts cluster? What training gaps appear?

Systematic improvement happens when data reveals patterns invisible to individual participants.

—

TECHNOLOGY ENABLES TRANSFORMATION

Modern fire extinguisher inspection services leverage several technology categories.

Cloud-based scheduling and coordination platforms manage hundreds of location calendars simultaneously, optimize technician assignments, generate schedules automatically, send notifications to stakeholders, and handle rescheduling with cascade updates.

Mobile inspection applications work offline (critical for sites with poor connectivity), sync automatically when connection available, guide technicians through standardized checklists, capture photos with compression and upload, collect digital signatures, and verify inspection locations through GPS.

Compliance dashboards provide real-time status across all locations, generate audit-ready reports instantly, flag exceptions requiring attention, track equipment issues through resolution, and visualize trends over time.

Communication automation handles pre-inspection notifications, confirmation tracking, post-inspection reporting, issue escalation, and service scheduling without human involvement in routine scenarios.

Integration capabilities connect fire safety data with existing facility management systems, eliminating duplicate entry and ensuring consistency across organizational platforms.

—

IMPLEMENTATION REALITIES

Organizations considering systematic fire extinguisher inspection services typically progress through several phases.

Assessment Phase

Professional providers start with understanding current state:

- How many locations, what types of facilities?

- What equipment populations exist?

- Who currently performs inspections, on what schedule?

- What documentation systems are in place?

- Where are the pain points and compliance gaps?

Assessment typically takes 1-2 weeks, produces detailed facility database and implementation plan customized to organization’s specific situation.

Setup Phase

Platform configuration with facility data, route optimization initial design, technician training, site manager communication, and pilot testing with representative locations.

Setup typically spans 2-4 weeks depending on organization size and complexity. Pilot programs with 10-25 locations validate approaches before full deployment.

Rollout Phase

Phased deployment by region prevents overwhelming anyone. Rather than switching all 300+ locations simultaneously (chaos), systematic rollout might be:

- Week 1: Northeast region (75 locations)

- Week 2: Southeast region (75 locations)

- Week 3: Midwest region (75 locations)

- Week 4: West region (75 locations)

Each phase receives focused attention. Issues surface and resolve before moving forward. Stakeholders see success building progressively.

Optimization Phase

After full deployment, refinement continues:

- Route adjustments based on real-world experience

- Process improvements from field feedback

- Reporting customization for different stakeholder needs

- Integration setup with other facility systems

Optimization never really ends—continuous improvement becomes ongoing operational approach.

48Fire manages entire implementation, requiring minimal client resource investment beyond initial data provision and stakeholder communication.

—

COST CONSIDERATIONS

Multi-location fire extinguisher inspection services represent investments with measurable returns.

Typical implementation investments:

- Initial equipment inventory and setup: $8,000-15,000 (one-time)

- Platform configuration: $3,000-5,000 (one-time)

- Training and onboarding: $2,000-4,000 (one-time)

Ongoing monthly investments:

- Platform/technology: $1,500-3,500 monthly (volume-based pricing)

- Professional inspection services: $35-75 per location monthly

Organizations with 300 locations might invest $10,500-22,500 monthly for comprehensive systematic service versus $12,000-20,000 they’re already spending through chaotic manual approaches.

Net cost difference: Often minimal or negative (systematic service costs similar to current spending)

Value difference: Dramatic (compliance improvement, time recapture, risk reduction, audit confidence)

Return on investment comes primarily from:

- Avoided compliance violations ($15,625 per serious OSHA violation)

- Reduced administrative time (staff focused on value-add activities vs. coordination)

- Prevented equipment failures (systematic inspection catches issues before emergencies)

- Insurance benefits (documented compliance supports favorable underwriting)

- Management time reclaimed (no more fire safety crisis management)

—

COMMON QUESTIONS

How long does transformation take?

Typical timeline: 8-12 weeks from initial assessment to full deployment across 300+ locations. Organizations see benefits in first deployed region within 3-4 weeks.

What if locations have different requirements?

Platforms accommodate variation. Each location can have different equipment types, local fire code requirements, scheduling preferences, and inspection protocols. Flexibility exists where needed while maintaining consistency where valuable.

Can we use our existing staff?

Yes. Technology platforms support both professional service providers and internal facility teams. Organizations with existing technicians can adopt systematic approaches while maintaining current staffing. Training ensures successful adoption regardless of background.

What about unstaffed or 24/7 facilities?

Scheduling flexibility accommodates any operating pattern. Unstaffed locations coordinate access with responsible parties. 24/7 facilities schedule during optimal windows. Remote locations receive less frequent but thorough visits. Reality drives approach, not rigid protocols.

Do we own the data?

Completely. Organizations access all inspection data anytime, export in multiple formats, grant temporary access to auditors or regulators, and maintain historical records indefinitely. Data portability prevents vendor lock-in.

What if service doesn’t meet expectations?

Professional providers focus on long-term relationships, not contractual obligations. Performance metrics track service quality continuously. Issues receive immediate attention. Organizations can modify scope or transition if expectations aren’t met—though high client retention suggests this rarely becomes necessary.

—

BEYOND FIRE EXTINGUISHERS

Organizations implementing systematic fire extinguisher inspection services often expand to comprehensive fire protection management.

Integrated services include:

- Fire alarm system testing and maintenance

- Fire sprinkler inspection and testing

- Emergency lighting verification

- Fire door and damper inspection

- Special hazard system maintenance

- Exit sign compliance

48Fire provides unified fire protection services coordinating all testing and maintenance through single platform, ensuring nothing gets overlooked while simplifying vendor management.

Comprehensive approaches deliver additional benefits:

- Single point of contact for all fire safety needs

- Coordinated scheduling across all systems

- Consolidated compliance reporting

- Simplified audit preparation

- Reduced vendor management overhead

Fire safety becomes managed process rather than collection of disconnected vendor relationships.

—

THE FUNDAMENTAL SHIFT

Here’s what actually changes when organizations move from manual chaos to systematic fire extinguisher inspection services:

FROM: Compliance as necessary evil requiring constant attention

TO: Compliance as managed background process requiring minimal oversight

FROM: Hoping inspections happen correctly

TO: Knowing inspections happen correctly with evidence

FROM: Scrambling during audits to prove compliance

TO: Producing instant documentation demonstrating systematic approach

FROM: Treating fire safety as procurement problem (buying services)

TO: Treating fire safety as operational problem (managing systems)

The compliance requirements don’t change—NFPA 10 still mandates monthly inspections at 30-day intervals with proper documentation. The execution changes completely.

Technology enables it. Professional coordination implements it. Systematic approaches maintain it.

Results compound over time. Year one sees immediate efficiency gains. Year two adds predictive capabilities from accumulated data. Year three enables proactive equipment management preventing failures before they occur.

Organizations sophisticated about operational excellence eventually apply those same principles to fire safety compliance. When they do, multi-location inspection transforms from resource drain to well-managed process delivering genuine risk reduction at reasonable cost.

—

START YOUR TRANSFORMATION

Multi-location fire extinguisher inspection complexity doesn’t resolve itself. Organizations either accept ongoing inefficiency and compliance risk, or they implement systematic approaches that eliminate both.

48Fire provides complete multi-location fire safety solutions including:

✓ Comprehensive equipment inventory across all facilities

✓ Cloud-based inspection management and coordination

✓ Certified field technicians with standardized protocols

✓ Real-time compliance visibility and reporting

✓ Route optimization and scheduling automation

✓ Digital documentation and audit support

✓ On-site issue resolution capabilities

✓ Complete implementation and ongoing optimization

Schedule Assessment: Contact 48Fire at [/contact-us](/contact-us) to discuss your multi-location fire safety challenges. We’ll analyze current approaches, identify improvement opportunities, and design solutions delivering measurable time reduction, cost efficiency, and compliance confidence.

Stop accepting fire safety chaos as inevitable. Start benefiting from systematic approaches that scale effortlessly across hundreds of locations while actually improving equipment reliability and regulatory compliance.

Professional fire protection shouldn’t be complicated. It should be systematic.

—

FREQUENTLY ASKED QUESTIONS

How many locations make systematic inspection services worthwhile?

Benefits typically become compelling around 25-50 locations. Below that, manual coordination remains manageable. Above that, complexity overwhelms manual approaches. Organizations with 100+ locations almost always benefit significantly from systematic services. Even smaller multi-location organizations (10-20 facilities) gain value from reduced administrative burden and improved compliance confidence.

What happens during the transition period?

Phased rollout means some locations continue on old systems while others move to new approaches. Platform supports hybrid operations during transition. Corporate visibility spans both, preventing gaps. Transition periods typically last 4-8 weeks depending on organization size, with each location switching once and staying switched.

Can we pilot the approach before committing fully?

Absolutely. Many organizations start with 15-25 representative locations for 2-3 months. Pilot demonstrates benefits, identifies issues, proves concept before broader deployment. 48Fire supports pilot programs with same technology and service quality as full implementations, providing valid assessment basis.

How does this work across different states with varying fire codes?

Platform configuration supports jurisdiction-specific compliance rules. Inspection protocols adapt based on location. Technicians receive prompts highlighting local requirement variations. Corporate compliance team maintains jurisdiction database. Single system accommodates regional variation while ensuring nothing gets missed.

What if we have unique equipment or special requirements?

Systematic approaches accommodate uniqueness better than manual processes. Unusual extinguisher types load into inventory with appropriate inspection protocols. Specialized requirements configure into location-specific checklists. Platform flexibility supports standardization where appropriate and customization where necessary.

Do you service remote or hard-to-reach locations?

Yes. Route optimization actually helps with remote locations by grouping them efficiently. Service frequency may adjust (some remote sites receive quarterly comprehensive inspections vs. monthly quick checks) based on risk assessment and practical access. Technology enables flexible approaches supporting any facility configuration.

How do you handle inspections during facility renovations or unusual circumstances?

Scheduling system accommodates exceptions easily. Locations undergoing renovation can reschedule or receive modified inspections focused on accessible areas. Temporary closures suspend scheduling automatically and resume when facility reopens. System flexibility prevents rigid protocols from forcing impractical requirements.

Can we get historical data from before implementation?

Platform can import existing inspection records if available in usable formats. Most organizations prioritize recent data (past 12-24 months) for migration while accepting older records may not transfer. Going forward, complete perfect documentation matters more than perfect historical archives. Organizations with strong existing records can migrate more; those with weak documentation start fresh with better systems.