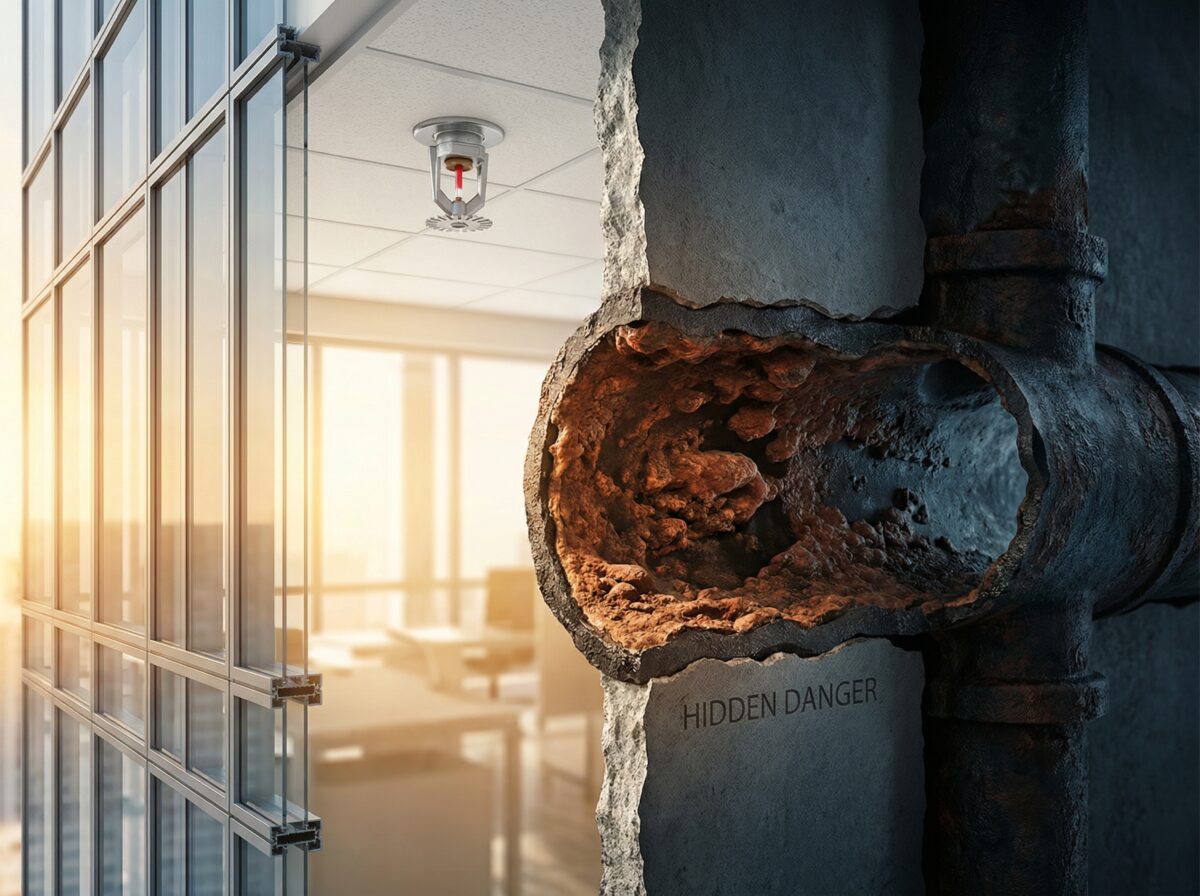

The Hidden Maintenance Mistake Many Skip in Fire Sprinkler Systems

They check the heads. They test the alarms. They verify the water pressure.

But they never check inside the pipes.

This single oversight causes more sprinkler system failures than any other maintenance mistake. And most building owners don’t know it’s happening until a fire reveals the problem.

The mistake: Skipping internal pipe obstruction investigation required every 5 years by NFPA 25.

The consequence: Systems that look perfect on the outside but can’t deliver water when fires occur.

—

What’s Hiding in Your Pipes

The Problem Nobody Sees

Fire sprinkler pipes sit filled with water (wet systems) or air (dry systems) for years between activations. During that time, several processes degrade pipe interiors:

In wet pipe systems:

- Microbiologically influenced corrosion (MIC) from bacteria in water

- Tuberculation (rust scale buildup) reducing effective pipe diameter

- Mineral deposits from hard water

- Sediment accumulation in low points

In dry pipe systems:

- Internal corrosion from condensation and oxygen exposure

- Scale flaking creating potential obstructions

- Air compressor oil contamination

- Foreign material from installation or repairs

The visibility problem: All of this happens inside pipes that appear perfectly normal from outside.

—

The Inspection Everyone Skips

NFPA 25 Section 14.2.1: Internal Pipe Obstruction Investigation

Requirement: Investigate interior condition of piping every 5 years for dry pipe systems and when conditions suggest potential obstruction for wet systems.

Method: Remove representative pipe samples, visually inspect interior, measure wall thickness if corrosion suspected, photograph conditions, document findings.

Why contractors skip it:

“It’s disruptive” – Requires cutting pipes, draining sections, interrupting protection

“It’s expensive” – Costs $2,000-$5,000 for comprehensive investigation

“System looks fine” – External appearance doesn’t reveal internal problems

“Never had issues” – Absence of fires means system never tested under real conditions

The reality: This investigation is the only way to detect developing problems before they cause system failures during actual fires.

—

What We Find When We Look

Case 1: The 15-Year-Old Dry Pipe System

Building: 120,000 SF warehouse, unheated

Last internal inspection: Never (system installed 2009)

Reason for investigation: Routine 5-year requirement

Investigation process:

- Selected 8 representative pipe locations across system

- Cut 12-inch sections from branch lines and mains

- Documented interior conditions photographically

- Measured remaining wall thickness ultrasonically

Findings:

Branch line sample 1: Heavy tuberculation reducing 2.5″ nominal pipe to 1.8″ effective diameter (28% reduction)

Branch line sample 2: Interior scale flaking, creating loose debris that could block heads during activation

Main line sample 1: Wall thickness reduced from 0.154″ original to 0.092″ current (40% reduction)

Main line sample 2: Severe pitting corrosion at 6 o’clock position where condensation accumulates

Impact analysis:

- Friction loss through corroded pipe 150% higher than design calculations assumed

- Effective pipe diameter reduction meant system couldn’t deliver designed flow rates

- Flaking scale posed obstruction risk during activation

- Wall thickness reduction created leak/burst risk

Recommendation: Replace 40% of system piping (worst sections), convert from compressed air to dry nitrogen (reduce future corrosion), increase inspection frequency to 3 years.

Cost if not discovered: System failure during fire, inadequate water delivery, potential catastrophic loss estimated $8M-$15M

Cost to repair: $285,000 phased over 6 months

—

Case 2: The “Maintained” Wet Pipe System

Building: 8-story office building

Age: 22 years

Maintenance history: Annual inspections by local contractor (visual only)

Investigation trigger: Building sale, buyer’s due diligence inspection

Process:

- 6 pipe samples across 8 floors

- Interior inspection and photography

- Water quality analysis

- Flow test comparison to original commissioning data

Findings:

Visual inspection: All pipe samples showed heavy tuberculation (rust scale buildup)

Measurement: Effective pipe diameter reduced 25-35% across all samples

Water quality: High iron content (8.2 mg/L vs. 0.3 mg/L acceptable), bacteria present indicating MIC

Flow test: Actual flow 68% of design flow at same pressure (pipes can’t deliver designed water)

The hidden problem: Annual visual inspections never detected this because:

- External pipe appearance normal

- No leaks or obvious problems

- System held pressure during tests

- Sprinkler heads in good condition

Only internal inspection revealed: System fundamentally compromised despite appearing functional.

Impact on building sale:

- Buyer demanded $420,000 credit for pipe replacement

- Sale delayed 45 days for remediation planning

- Seller’s position weakened in negotiations

If discovered during fire instead of inspection: System would have delivered inadequate water, fire would have exceeded control capacity, property damage would have been severe.

—

Case 3: The System That Failed During Testing

Building: Manufacturing facility

System type: Wet pipe with fire pump

Age: 12 years

Previous maintenance: “We test it annually”

Investigation trigger: Fire pump flow test showed pressure drop inconsistent with hydraulic calculations

Initial suspicion: Pump performance degrading

Pump test results: Pump delivering rated flow at rated pressure (functioning correctly)

Revised suspicion: System demand exceeding available supply

Hydraulic recalculation: System should deliver adequate flow based on pipe sizes

Internal pipe investigation: Revealed the actual problem

Findings:

- Microbiologically influenced corrosion created tubercles (rust mounds) inside pipes

- Tubercles reduced effective diameter by 30-40%

- Rough interior surface increased friction loss dramatically

- Combination meant system couldn’t deliver design flow despite pump working correctly

Root cause analysis:

- Building water supply had bacteria promoting MIC

- Closed system allowed bacterial growth over 12 years

- No water treatment or filtration

- No internal inspections to detect developing problem

Solution implemented:

- Replace 8,200 linear feet of most affected pipe

- Install water filtration and treatment system

- Quarterly water quality testing

- 3-year internal inspection cycle

Cost: $340,000 (pipe replacement) + $28,000 (water treatment) = $368,000

Prevented loss: Manufacturing facility fire could have caused $15M-$25M damage if system failed

—

Why This Happens (And Keeps Happening)

The “Out of Sight, Out of Mind” Problem

Fire sprinkler maintenance focuses on visible, accessible components:

- Sprinkler heads (can see them)

- Control valves (can operate them)

- Fire alarm panel (can test it)

- Water pressure (can measure it)

Pipe interiors require destructive investigation—cutting pipes to inspect inside. Contractors avoid this because:

- System must be drained (protection temporarily compromised)

- Pipes must be cut and replaced (material and labor cost)

- Results might require expensive remediation (nobody wants to deliver bad news)

- Building owners resist invasive testing (if it ain’t broke, don’t fix it)

The problem: By the time internal pipe problems become visible externally (leaks, failures, inadequate flow during fires), extensive damage has occurred.

—

The Cost Justification Challenge

Building owner perspective: “You want me to pay $5,000 to cut up my pipes and tell me I need to spend $300,000 replacing them? The system works fine!”

Contractor perspective: “If I recommend internal inspection and find major problems, owner will blame me and switch contractors.”

Result: Inspection gets skipped until:

- Code enforcement requires it

- Building sale triggers due diligence

- Insurance audit demands it

- Fire reveals system inadequacy

—

The “Annual Inspection” Illusion

Most building owners believe “annual fire sprinkler inspection” includes everything necessary for system reliability.

What annual inspections typically include:

- Visual sprinkler head inspection (damage, corrosion, painting)

- Control valve position verification

- Gauge reading documentation

- Alarm test

- Basic flow test

What annual inspections DON’T include:

- Internal pipe condition assessment

- Hydraulic recalculation verifying continued adequacy

- Water quality analysis

- Detailed corrosion evaluation

- Obstruction investigation

The gap: Systems pass annual inspections while developing serious internal problems that won’t be discovered until they fail.

—

How to Actually Maintain Fire Sprinkler Systems

Follow Complete NFPA 25 Requirements

NFPA 25 establishes comprehensive ITM schedules. Internal pipe investigation is just one of many requirements contractors commonly skip.

Complete NFPA 25 compliance includes:

Weekly: Control valve position, fire pump operation

Monthly: Sprinkler head visual, alarm device check

Quarterly: Detailed head inspection, dry system air pressure, gauges

Annual: Flow testing, fire pump full-load test, valve operation, alarm functionality

Every 5 years: Internal pipe obstruction investigation, hydrostatic pressure test (select components), fire pump overhaul

Key point: Each requirement exists because skipping it creates specific failure risks. Internal pipe investigation isn’t optional—it’s essential.

—

Use Qualified Contractors

Not all fire sprinkler contractors provide comprehensive NFPA 25 compliance.

Questions to ask contractors:

“Do you perform 5-year internal pipe obstruction investigations?”

- If answer is “not unless problems suspected,” find different contractor

- Proper answer: “Yes, as required by NFPA 25 Section 14.2.1”

“How many pipe samples do you take during investigation?”

- Minimum: 1 sample per riser or system type

- Better: Representative samples across facility (6-10 typical)

“What happens if you find problems?”

- Poor answer: “We’ll let you know”

- Good answer: “We provide detailed report with photos, measurements, impact analysis, and remediation recommendations with cost estimates”

“Do you provide water quality analysis?”

- Indicates comprehensive approach beyond minimum requirements

- Shows understanding of corrosion mechanisms

—

Implement Proactive Monitoring

Between 5-year inspections, proactive monitoring can detect developing problems:

Water quality testing (annual):

- Iron content indicates corrosion activity

- Bacteria presence indicates MIC risk

- pH levels affect corrosion rates

Flow test trending:

- Compare results year over year

- Declining flow at same pressure indicates obstruction development

- Early detection enables intervention before major problems

Pressure monitoring:

- Unexplained pressure drops suggest leaks or obstructions

- Gradual pressure decline indicates system degradation

Visual indicators:

- Rusty water during drain-downs indicates internal corrosion

- Air quality in dry systems (moisture, oil contamination)

- Compressor runtime increases suggest air leaks from corrosion

[Talk to an Expert!](/contact-us)

—

What Internal Pipe Investigation Actually Involves

The Process Step-by-Step

Step 1: Planning and Coordination

- Identify representative sample locations

- Schedule during low-occupancy period

- Arrange temporary protection measures if needed

- Notify building occupants

Step 2: System Preparation

- Close control valves isolating sample sections

- Drain affected piping

- Verify no pressure remains

Step 3: Sample Removal

- Cut 12-18 inch pipe sections at selected locations

- Cap open ends temporarily

- Label samples with location information

Step 4: Interior Inspection

- Visual inspection with photography

- Measure remaining wall thickness (ultrasonic)

- Document tuberculation, scaling, pitting

- Assess obstruction risk from loose debris

Step 5: Water Quality Analysis (wet systems)

- Collect water samples before draining

- Test for iron, bacteria, pH, dissolved oxygen

- Identify corrosion mechanisms

Step 6: System Restoration

- Install new pipe sections at sample locations

- Pressure test new joints

- Refill system

- Restore to service

- Verify operation

Step 7: Reporting

- Detailed findings with photos

- Measured data (wall thickness, diameter reductions)

- Impact analysis on system performance

- Remediation recommendations

- Cost estimates for corrections

Typical timeline: 2-3 days for investigation + restoration

Typical cost: $2,000-$5,000 for 6-10 samples

—

When to Investigate (Beyond 5-Year Requirement)

Conditions Suggesting Potential Obstruction

NFPA 25 requires investigation when:

Observed conditions indicate problems:

- Rusty water during drain-downs

- Unusual flow test results

- Pressure anomalies

- Visible external corrosion

- Age exceeding 50 years (white/black steel) or 30 years (copper)

Changes in water supply:

- New water source

- Water treatment changes

- Known corrosive water conditions

System modifications:

- Significant additions or alterations

- Changed from wet to dry (or vice versa)

- After major repairs

Building use changes:

- Different occupancy increasing fire load

- Storage height increases

- Hazard classification changes

Due diligence events:

- Building sale or purchase

- Major lease renewals

- Insurance policy changes

- Refinancing requirements

—

The Cost-Benefit Reality

Investigation Costs vs. Failure Costs

5-year internal pipe investigation: $2,000-$5,000

Typical findings requiring remediation: 30-50% of investigations identify issues

Average remediation cost when problems found: $100,000-$400,000 (phased over time)

Cost of system failure during fire: $5M-$25M+ (property damage, business interruption, liability)

The math: Investigation is cheap insurance. Even expensive remediation costs far less than single system failure during actual fire.

—

Phased Remediation Approach

When investigation reveals extensive problems, phased remediation spreads costs:

Phase 1 (Year 1): Replace most severely affected sections (highest failure risk)

Phase 2 (Year 2-3): Replace moderately affected sections

Phase 3 (Year 3-5): Replace remaining sections showing early deterioration

Phase 4 (Ongoing): Implement corrosion control measures (water treatment, nitrogen systems, protective coatings)

Benefit: Addresses most critical risks immediately while spreading total cost across multiple budget cycles.

—

48Fire’s Comprehensive Maintenance Approach

We provide complete NFPA 25 compliance—including the inspections others skip.

Our 5-year internal pipe investigation includes:

Comprehensive sampling: 8-12 samples per system (more than minimum)

Advanced diagnostics: Ultrasonic thickness measurement, water quality analysis, corrosion mechanism identification

Detailed reporting: Professional documentation with photos, measured data, impact analysis

Remediation planning: Prioritized recommendations, phased implementation options, accurate cost estimates

Ongoing monitoring: Annual water quality testing, flow test trending, condition tracking

The result: Early detection of developing problems, planned remediation avoiding emergency failures, maintained system reliability throughout building life.

—

Key Takeaways

The hidden maintenance mistake: skipping internal pipe obstruction investigation required every 5 years by NFPA 25 Section 14.2.1. This single oversight causes more system failures than any other maintenance gap because pipe interior degradation happens invisibly while external appearance remains normal.

Real-world investigations reveal extensive problems: 15-year dry system with 28% diameter reduction and 40% wall thickness loss, 22-year wet system with 68% of design flow capacity, 12-year system with MIC creating 30-40% obstruction despite pump functioning correctly.

Complete NFPA 25 compliance requires: weekly control valve checks, monthly visual inspections, quarterly detailed head inspection, annual flow testing and fire pump tests, and 5-year internal pipe obstruction investigation plus water quality analysis.

Investigation costs $2,000-$5,000 and takes 2-3 days. When problems found (30-50% of investigations), remediation costs $100,000-$400,000 but prevents $5M-$25M+ losses from system failures during actual fires. Phased remediation spreads costs across multiple years while addressing highest risks first.

Ready to implement comprehensive fire sprinkler maintenance including internal pipe investigation?

[Talk to an Expert!](/contact-us)

—