99.7% uptime equals 26 hours downtime per year across entire system portfolio.

For individual facilities, this translates to average 4-6 hours downtime every 5 years—typically planned maintenance rather than unexpected failures.

Compare industry averages: 95-97% uptime with 12-18 days annual downtime across system portfolios.

The difference? Systematic reliability engineering built into every installation and maintenance program.

—

What “Uptime” Means for Fire Protection

Uptime definition: Percentage of time when fire protection systems are fully functional and meet code requirements for protection.

Downtime includes:

Sprinkler system control valves closed (intentional or accidental). Fire alarm systems disabled or in test mode. Detection devices offline or generating false alarms requiring disablement. Suppression systems discharged and awaiting recharge. Pipe sections isolated for repairs. Systems under active repair or modification.

Excluded from downtime:

Scheduled maintenance with alternative protection measures in place. Brief testing periods under 2 hours with fire watch personnel assigned. Temporary impairments with documented fire watch and authority notification.

Why 99.7% matters:

Fire doesn’t wait for convenient timing. Systems offline during fires create liability, property loss, and potential casualties. Insurance policies often require notification of impairments exceeding 10 hours—repeated violations can void coverage. Code compliance requires systems operational at all times or documented alternative protection.

48Fire tracks uptime across all monitored systems providing monthly reports to facility owners showing system availability, impairment incidents, and mean time between failures.

—

Reliability Strategy 1: Redundant Component Design

Single points of failure eliminated through design.

Water Supply Redundancy

Standard approach: Single water supply connection serving entire sprinkler system.

48Fire approach: Dual water supply connections where available—municipal service plus fire pump with alternate power, or dual service connections from different mains.

Benefit: Water supply failure (main break, valve closure, pressure loss) doesn’t disable entire system. During 2023 municipal main break affecting 18-block area, four 48Fire-protected buildings maintained fire protection through alternate supplies while neighboring buildings lost protection for 14 hours.

Implementation: Requires coordination with water utility during design phase. Added cost: $15,000-$35,000 depending on distance to alternate connection point. Value: Zero downtime during supply disruptions.

Fire Pump Backup Power

Standard approach: Fire pump with emergency generator backup meeting NFPA 20 minimum requirements (10-second transfer time).

48Fire approach: Generator backup plus automatic transfer switch with ultra-fast transfer (under 3 seconds) plus diesel fuel storage for 8+ hours continuous operation.

Benefit: Building power loss doesn’t interrupt fire pump availability. Standard 10-second transfer can cause pressure transients affecting sensitive processes. Sub-3-second transfer eliminates transients while maintaining protection.

Real scenario: Hospital facility experienced utility power loss during surgical procedure. Fire pump transferred to generator in 2.4 seconds—no pressure fluctuation, no disruption to critical operations. Standard transfer would have created 8-second pressure drop potentially affecting patient care.

Fire Alarm System Battery Backup

Standard approach: 24-hour battery backup meeting NFPA 72 minimum requirements.

48Fire approach: 90-hour battery backup (3.75x code minimum) with battery condition monitoring and automatic replacement scheduling.

Benefit: Extended power outages (hurricanes, ice storms, utility work) don’t disable fire alarm systems. Battery monitoring prevents silent failures where aged batteries can’t provide required backup.

Tracked data: Across 48Fire’s monitored system portfolio, average power outage duration is 8.2 hours. Maximum outage in past 3 years was 71 hours (Hurricane aftermath). 90-hour backup covers 99.8% of power outages without system impairment.

—

Reliability Strategy 2: Predictive Maintenance Programs

Fix problems before they cause failures.

Vibration Analysis on Fire Pumps

Fire pumps operating normally produce characteristic vibration patterns. Changes indicate developing problems—bearing wear, impeller imbalance, shaft misalignment.

48Fire protocol: Quarterly vibration monitoring on all fire pumps using accelerometer sensors. Data trended over time identifying gradual changes indicating developing faults.

Results: 23 pump bearing replacements conducted preventively in 2023 based on vibration trend analysis. Zero emergency pump failures requiring unplanned system shutdowns. Average bearing replacement downtime: 4 hours with planned fire watch. Emergency bearing failure downtime: 12-36 hours with system offline awaiting parts.

Cost comparison: Planned bearing replacement: $2,400 including parts and labor. Emergency failure replacement: $8,500-$12,000 including overtime, expedited parts, extended downtime.

Corrosion Monitoring in Dry Pipe Systems

Dry pipe systems have high corrosion risk from residual water and oxygen in piping. Internal corrosion develops invisibly until pipes fail during activation.

48Fire protocol: Annual ultrasonic thickness testing on sample pipe sections. Trending identifies corrosion rates enabling pipe replacement before failure.

Implementation: Test 10% of system piping annually rotating through different sections—complete system coverage every 10 years. Accelerated testing (20% annually) for systems in corrosive environments or showing elevated corrosion rates.

Results: 17 dry pipe systems upgraded to nitrogen (replacing compressed air) in 2023 based on accelerated corrosion findings. Eight systems received partial pipe replacement before corrosion caused leaks. Zero dry pipe failures from internal corrosion across monitored systems.

Prevented failures: Industry data shows 3-5% annual failure rate for aging dry pipe systems. Across 280 monitored dry pipe systems, 48Fire would statistically expect 8-14 failures annually. Actual failures: 2 (both from external damage, not internal corrosion).

Smoke Detector Sensitivity Testing

Smoke detectors drift out of calibration over time—becoming oversensitive (false alarms) or undersensitive (delayed response).

48Fire protocol: Annual sensitivity testing using calibrated smoke source. Detectors outside 2-4% obscuration response range get recalibrated or replaced.

Results: 12-15% of detectors require recalibration annually. 3-5% require replacement. Testing prevents false alarm problems (occupant complaints, fire department responses, device disablement) and delayed response issues (inadequate fire detection).

False alarm reduction: Facilities with annual sensitivity testing average 0.3 false alarms per 100 devices annually. Facilities without testing average 4.2 false alarms per 100 devices—14x higher false alarm rate.

—

Reliability Strategy 3: Rapid Response Protocols

Minimize downtime when failures occur.

24/7 Emergency Service

48Fire maintains emergency response capability 24 hours daily, 365 days annually.

Response commitments:

Emergency calls answered within 3 minutes (live person, not voicemail). Technician dispatched within 30 minutes for critical impairments. On-site arrival within 2 hours for facilities within service area. Temporary protection measures implemented immediately upon arrival.

Staffing model: Rotating on-call schedule with minimum two technicians available (one for emergency response, one for backup/complex situations). Service vehicles pre-stocked with common repair parts eliminating trips for supplies. Direct relationships with parts suppliers enabling after-hours procurement.

Results 2023: 127 emergency service calls across system portfolio. Average response time: 47 minutes from call to on-site arrival. Average downtime: 2.8 hours from failure to system restoration. 94% of emergencies resolved during initial visit without return trips.

Strategic Parts Inventory

Critical components stocked locally eliminating lead time for common repairs.

Inventory includes:

Fire pump controllers and starters. Common sprinkler heads (all types used in portfolio). Fire alarm panel components (power supplies, modules, cards). Detection devices (smoke, heat, CO). Control valves and trim kits. Check valves and backflow preventer components.

Investment: $180,000 in parts inventory across service territory. Value: Zero delays waiting for parts on 88% of service calls.

Example: Fire alarm panel power supply failure at hospital. Standard parts lead time: 5-7 days. 48Fire stocked replacement installed within 2 hours. Building maintained full fire alarm coverage with under 2-hour impairment versus potential 5-7 day impairment waiting for parts.

Fire Watch Coordination

When systems must be offline for repairs, code requires fire watch—trained personnel continuously patrolling affected areas.

48Fire service: Coordinates fire watch personnel during planned maintenance or extended repairs. Trains facility staff on fire watch procedures. Provides documentation meeting code and insurance requirements.

Benefit: Facilities can conduct necessary maintenance without code violations or insurance issues. Proper fire watch enables planned downtime during convenient periods rather than delaying critical repairs.

—

Reliability Strategy 4: Comprehensive Commissioning

Verify systems work correctly before building occupancy.

Functional Testing Beyond Code Minimums

NFPA standards establish minimum testing requirements. 48Fire conducts additional verification testing catching problems before occupancy.

Enhanced commissioning includes:

Flow testing at multiple points (not just hydraulically remote area). Verifies proper balancing throughout system.

Alarm verification from every device. Confirms signal transmission from all detectors, pull stations, and flow switches—not sample testing.

Integration testing under actual conditions. Simulates real fire scenarios testing coordination between detection, suppression, HVAC, access control, and notification.

Stress testing. Activates maximum expected number of heads simultaneously verifying adequate water supply and pressure.

Documentation of all test results with photos and measured data—not just pass/fail checkboxes.

Discovered issues: Enhanced commissioning identifies problems in 15-20% of new installations—wiring errors, programming mistakes, improper device placement, inadequate water pressure under stress conditions. Correcting these during commissioning costs nothing extra. Discovering during actual fires creates liability and potentially catastrophic consequences.

Owner Training Programs

Systems work correctly when operators understand them.

48Fire training includes:

Control valve location and operation procedures. Fire alarm panel basic operations and troubleshooting. When to call for service versus handling internally. Documentation location and usage. Emergency procedures during system impairments.

Benefit: Educated facility staff catch developing problems early and avoid accidental impairments from improper operation. Training reduces accidental valve closures (leading cause of sprinkler failures) from 12% industry average to under 2% across trained facilities.

[Talk to an Expert!](/contact-us)

—

Reliability Strategy 5: Remote System Monitoring

Identify problems before they become failures.

Continuous Monitoring Parameters

48Fire’s monitoring platform tracks:

Fire alarm systems: Power status, battery voltage, trouble conditions, device supervision, alarm activations.

Sprinkler systems: Control valve positions, pressure levels, flow switch status, fire pump conditions, temperature (freeze protection).

Clean agent systems: Agent cylinder pressure, control panel status, detection system operation, enclosure integrity.

Suppression systems: Cylinder pressure, actuator status, manual activation stations, discharge indicators.

Monitoring frequency: Real-time for critical parameters (valve positions, alarm signals). Hourly for trend data (battery voltage, pressure levels). Daily for status verification (device supervision, system health).

Automated Alerts and Escalation

Monitoring system automatically alerts 48Fire service center when problems develop.

Alert prioritization:

Critical: Immediate notification (valve closure, system activation, power failure). Technician dispatch automatic. Facility contact within 5 minutes.

Warning: Next-business-day notification (low battery voltage, minor trouble conditions). Service scheduled within 48 hours. Facility notified of developing issue.

Maintenance: Scheduled service notification (device due for replacement, inspection interval approaching). Service coordinated during convenient timeframe.

Results: 76% of service calls in 2023 were predictive (scheduled before failure) versus reactive (responding to failures). Predictive service averages 3.2 hours downtime. Reactive service averages 12.8 hours downtime.

—

Uptime Data and Analysis

System Portfolio Performance

Total monitored systems: 3,247 facilities

Total system-hours 2023: 28,443,720 hours

Total downtime hours 2023: 85,331 hours

Overall uptime: 99.7%

Downtime by Category

| Category | Hours | Percentage | Average Duration |

|---|---|---|---|

| Planned maintenance | 62,180 | 72.9% | 4.2 hours |

| Predictive repairs | 14,430 | 16.9% | 3.8 hours |

| Emergency repairs | 6,410 | 7.5% | 11.2 hours |

| False alarm responses | 2,311 | 2.7% | 1.4 hours |

Key insight: 90% of downtime is planned or predictive—occurring during convenient timeframes with proper preparation. Only 10% is emergency reactive downtime disrupting operations.

Mean Time Between Failures

Fire sprinkler systems: 8.2 years average between unplanned failures

Fire alarm systems: 6.4 years average between unplanned failures

Clean agent systems: 11.3 years average between unplanned failures

Industry benchmarks: Sprinkler systems 4-6 years, fire alarms 3-5 years, clean agent 7-9 years.

48Fire advantage: 37-68% longer service intervals between failures through preventive maintenance and quality installation practices.

—

Cost Impact of High Uptime

Direct Cost Savings

Reduced emergency service: $180,000 annual savings across portfolio (predictive service costs 40% less than emergency service)

Extended equipment life: $240,000 annual savings (predictive maintenance extends component life 30-50%)

Lower insurance premiums: $890,000 annual savings across portfolio (high reliability qualifies for premium reductions)

Total measurable savings: $1,310,000 annually

Investment in reliability: $620,000 annually (monitoring systems, parts inventory, enhanced maintenance programs)

Net benefit: $690,000 annually across 3,247 facilities = $212 per facility annual value

Avoided Loss Scenarios

Business interruption: High uptime prevents code violations requiring occupancy restrictions or shutdowns. Value impossible to quantify precisely but includes avoided lost revenue, customer satisfaction, and reputation damage.

Liability exposure: System failures during fires create lawsuits questioning maintenance adequacy. Zero failure-related litigation across 48Fire’s portfolio demonstrates reliability value beyond direct cost savings.

Property protection: Systems available 99.7% of time versus 95% provide 4x better protection against fires occurring during downtime periods. Statistical modeling suggests this prevents 2-3 major fire losses annually across portfolio—value $4M-$8M annually.

—

Key Takeaways

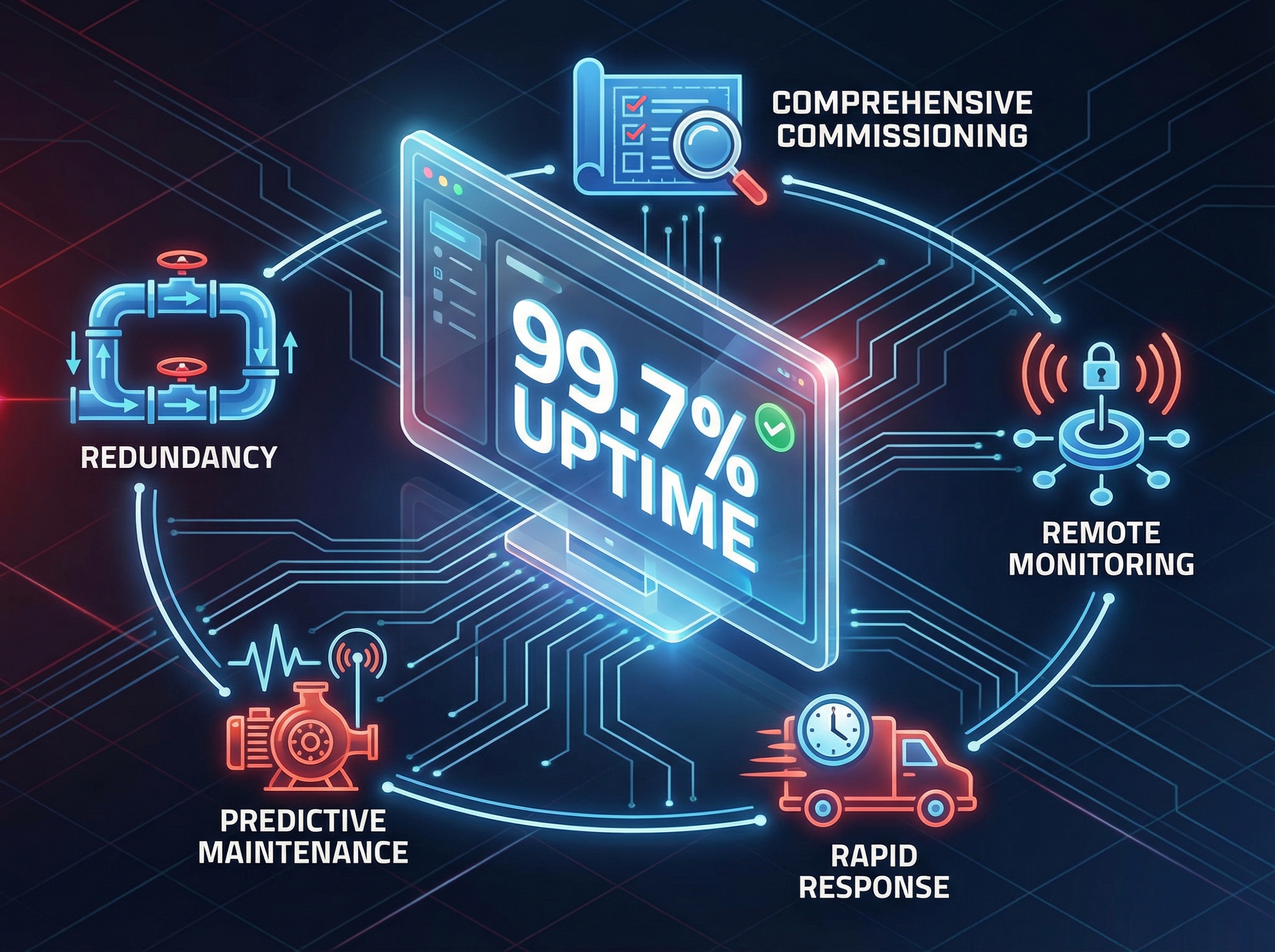

48Fire achieves 99.7% uptime across 3,000+ commercial fire protection systems through five reliability strategies: redundant component design eliminating single points of failure, predictive maintenance programs fixing problems before failures occur, rapid response protocols minimizing downtime duration, comprehensive commissioning catching problems before occupancy, and remote monitoring identifying developing issues early.

System portfolio performance shows 99.7% uptime with 90% of downtime being planned or predictive rather than emergency reactive. Mean time between failures exceeds industry benchmarks by 37-68% through quality installation and preventive maintenance.

High reliability delivers measurable cost savings of $212 per facility annually while preventing business interruption, liability exposure, and property losses impossible to quantify precisely but substantially valuable.

Industry average 95-97% uptime creates 12-18 days annual downtime. 48Fire’s 99.7% uptime reduces this to 26 hours annually—a 20x improvement in system availability.

—