5 Signs Your Fire Extinguishers Are Due for Replacement

THE PROBLEM

Fire extinguishers don’t announce when they’ve reached end-of-life. No alarm sounds. No warning light flashes. Equipment simply sits on walls looking operational while internal degradation makes them increasingly unreliable.

Facilities assume extinguishers remain functional indefinitely with basic maintenance. Then hydrostatic testing reveals the truth: corroded shells, compromised valves, degraded agents. What appeared serviceable becomes scrap metal.

The replacement decision matters because:

- Continuing to use unreliable equipment creates false security

- Failed extinguishers during fires lead to catastrophic outcomes

- Compliance violations arise from keeping deficient units in service

- Replacement costs less than emergency failures and violations

This guide identifies the five definitive signs that fire extinguishers require replacement rather than continued service.

—

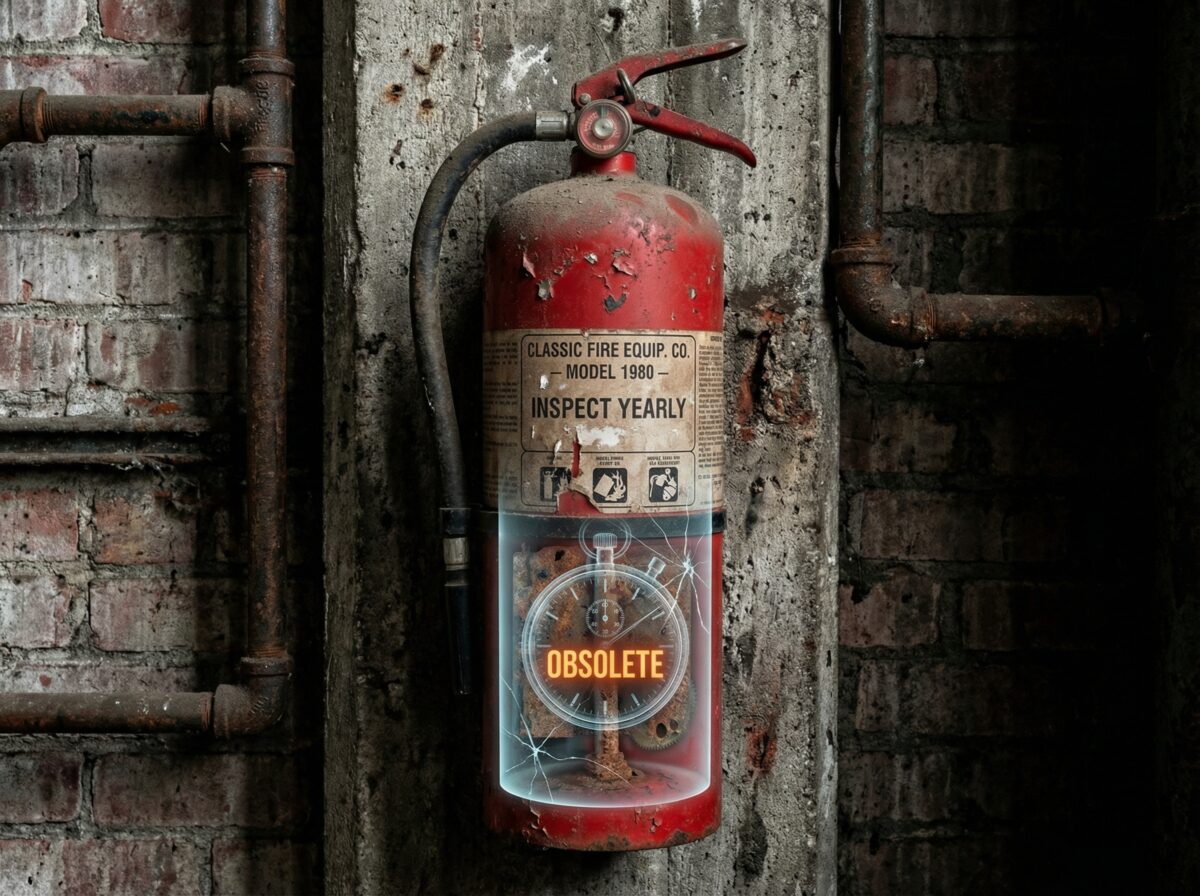

SIGN #1: AGE EXCEEDS MANUFACTURER LIFESPAN

THE BASELINE REALITY

Fire extinguishers have finite service lives. Manufacturing standards, materials, and technology improve over time, but existing equipment ages regardless.

Typical service life expectations:

| Extinguisher Type | Expected Service Life |

|---|---|

| Dry chemical (rechargeable) | 12-15 years with proper maintenance |

| CO2 (carbon dioxide) | 15-20 years with proper maintenance |

| Water and foam | 10-12 years with proper maintenance |

| Halogenated/clean agent | 15-20 years with proper maintenance |

| Disposable units (non-rechargeable) | Per manufacturer date, typically 10-12 years |

These expectations assume proper maintenance including regular inspections, timely recharging, and successful hydrostatic testing. Harsh environments or poor maintenance shorten actual service life significantly.

HOW TO DETERMINE AGE

Manufacturing date location:

- Stamped on metal nameplate attached to shell

- Usually includes month and year of manufacture

- May use code format requiring manufacturer reference

- Some older units lack clear dating

Service life calculation:

- Current year minus manufacturing year = equipment age

- Compare against expected service life for that extinguisher type

- Consider cumulative service history—units with multiple recharges and repairs may age faster

- Factor in environmental exposure

Example assessment:

- Dry chemical extinguisher manufactured in 2010

- Current year: 2025

- Equipment age: 15 years

- Expected service life: 12-15 years

- Conclusion: Replacement consideration warranted

THE REPLACEMENT DECISION

Equipment approaching or exceeding expected service life enters evaluation zone.

Factors supporting replacement:

- Manufacturing date exceeds typical lifespan for that type

- Equipment has experienced harsh environmental exposure

- Service history shows increasing maintenance issues

- Upcoming hydrostatic testing cost approaches replacement cost

- Technology improvements make newer units more effective

48Fire provides age-based replacement analysis helping facilities make cost-effective decisions about aging fire extinguisher equipment rather than continuing expensive maintenance on units nearing end-of-life.

—

SIGN #2: FAILED HYDROSTATIC TESTING

WHAT HYDROSTATIC FAILURE MEANS

Hydrostatic testing verifies pressure vessel integrity under stress exceeding normal operating conditions. When extinguishers fail this testing, they demonstrate inability to safely contain the pressures required for proper discharge.

Failure indicators during testing:

- Visible leakage at any point during pressurization

- Permanent deformation or bulging of shell

- Cracks appearing under pressure

- Rupture during testing (catastrophic failure)

- Any pressure loss during hold period

NFPA 10 requirement: Units failing hydrostatic testing must be condemned and removed from service permanently.

There is no repair option. Failed pressure vessels cannot be made safe for continued use. Replacement is mandatory, not optional.

WHY EXTINGUISHERS FAIL TESTING

Internal corrosion:

Most common failure cause. Moisture contamination over years creates rust that weakens shells from inside. External appearance may show no problems while internal degradation has critically compromised structural integrity.

Stress fractures:

Microscopic cracks develop from impact damage, repeated pressurization cycles, or manufacturing defects. These progress over time until hydrostatic testing reveals weakness.

Material fatigue:

Pressure vessels undergo stress during each discharge and recharge cycle. Over decades, metal fatigue accumulates even in properly maintained units.

Environmental damage:

Coastal environments, chemical facilities, high-humidity locations, and temperature extremes accelerate shell degradation beyond normal aging patterns.

POST-FAILURE PROTOCOL

When 48Fire technicians identify extinguishers that fail hydrostatic testing:

IMMEDIATE ACTIONS:

1. Unit permanently removed from service

2. Shell destroyed to prevent reuse (drilling holes, cutting, crushing)

3. Facility notification of failure with replacement recommendations

4. Temporary extinguisher installed maintaining code-required coverage

5. Documentation updated showing unit failure and replacement need

REPLACEMENT PLANNING:

- Assess whether failure indicates broader equipment population issues

- Consider whether similar-age units warrant preemptive replacement

- Evaluate if environmental factors contributed to premature failure

- Determine if different extinguisher types would perform better in that location

Failed hydrostatic testing provides definitive replacement signal—no judgment calls, no gray areas. The equipment is done.

—

SIGN #3: EXTENSIVE PHYSICAL DAMAGE OR CORROSION

DAMAGE BEYOND REPAIR

Some physical damage exceeds what maintenance can address.

SHELL DAMAGE REQUIRING REPLACEMENT:

Severe denting:

- Deep dents that crease metal significantly

- Damage affecting structural integrity

- Dents in bottom or top heads near seams

- Multiple impact points weakening overall structure

Corrosion penetration:

- Visible rust eating through shell material

- Pitting corrosion creating holes or near-holes

- Extensive surface corrosion indicating internal problems

- Rust at welds, seams, or threads

Handle/valve assembly damage:

- Broken operating handles that cannot be replaced

- Valve body cracks or breaks

- Damaged threads preventing proper seal

- Bent or damaged discharge assemblies beyond repair capability

Nameplate or identification loss:

- Missing manufacturer nameplate making specifications unknown

- Worn labeling preventing proper identification

- Inability to determine manufacturing date or service history

48Fire technicians assess damage during inspections, determining whether units can be repaired or require replacement. Facilities receive clear recommendations with photographic documentation supporting decisions.

ENVIRONMENTAL CORROSION PATTERNS

Certain environments accelerate fire extinguisher degradation requiring earlier replacement.

HIGH-RISK ENVIRONMENTS:

Coastal locations:

- Salt air accelerates external corrosion

- Average service life may decrease 20-30%

- More frequent inspections detect problems earlier

- Consider corrosion-resistant models for new installations

Chemical facilities:

- Airborne chemicals attack metal surfaces

- Agent contamination occurs more rapidly

- Specialized extinguisher types may be necessary

- Replacement cycles typically shorter than standard environments

High-humidity areas:

- Moisture promotes internal corrosion

- Dry chemical agents more prone to clumping

- External rust develops faster

- Consider sealed or pressurized storage areas

Temperature extremes:

- Freeze-thaw cycles stress seals and shells

- Extreme heat degrades agents and components

- Pressure fluctuations accelerate seal failure

- Specialized units designed for extreme temperatures may be warranted

Facilities in these environments should expect shorter equipment lifespans and budget accordingly for more frequent replacement.

THE COST CALCULATION

Attempting to repair extensively damaged extinguishers often costs more than replacement.

REPAIR VS. REPLACEMENT ANALYSIS:

Consider dry chemical extinguisher with significant corrosion and damaged valve:

- Shell reconditioning/repainting: $40-60

- Valve replacement: $50-75

- Internal cleaning: $30-40

- Recharge: $25-40

- Total repair: $145-215

New equivalent extinguisher:

- Purchase price: $150-250 depending on size/rating

- Initial service/installation: $25-50

- Total replacement: $175-300

When repair costs approach 60-70% of replacement cost, replacement becomes more economical—particularly for aging equipment likely to need additional service soon.

48Fire provides transparent cost comparisons helping facilities make financially sound decisions about repair versus replacement.

—

SIGN #4: REPEATED SERVICE ISSUES

THE PATTERN THAT SIGNALS END-OF-LIFE

Individual service needs are normal. Patterns of recurring problems indicate equipment approaching end-of-useful-life.

WARNING PATTERNS:

Recurring pressure loss:

- Unit requires recharging more frequently than similar equipment

- Pressure drops despite seal replacement

- Indicates valve wear or internal issues

- Repair costs accumulate without solving root problem

Multiple component failures:

- Valve replacement followed by hose failure followed by gauge issues

- Sequential failures indicate overall degradation

- Each repair extends life briefly before next failure

- Cumulative repair costs exceed replacement cost

Agent degradation issues:

- Dry chemical clumping despite proper storage

- Wet chemical separation or contamination

- Foam agent deterioration

- Suggests internal contamination or moisture infiltration

Chronic accessibility problems:

- Mounting bracket failures

- Recurring physical damage in same location

- Equipment repeatedly found obstructed

- May indicate improper location requiring unit relocation or different type

MAINTENANCE COST TRACKING

48Fire digital systems track cumulative maintenance costs per extinguisher, automatically flagging units where repair spending suggests replacement consideration.

COST THRESHOLD ANALYSIS:

Equipment maintenance tracking for 5-year period:

- Year 1: Recharge after use ($30)

- Year 2: Valve replacement and recharge ($125)

- Year 3: Hose replacement ($75)

- Year 4: Recharge and seal replacement ($45)

- Year 5: Internal examination reveals corrosion ($200 to repair)

- Cumulative: $475 over 5 years

Replacement cost: $200

Decision: Replace rather than continue repairing

This data-driven approach prevents throwing good money after bad equipment.

THE DIMINISHING RETURNS POINT

Every repair decision should consider:

- Current repair cost as percentage of replacement cost

- Likelihood of additional failures based on equipment age and condition

- Remaining expected service life even if current repair succeeds

- Opportunity to upgrade to more effective modern equipment

When repairs exceed 50% of replacement cost and equipment is beyond mid-life, replacement typically makes better financial sense.

—

SIGN #5: OBSOLETE OR DISCONTINUED MODELS

WHEN EQUIPMENT OUTLIVES SUPPORT

Technology advances. Manufacturers discontinue product lines. Eventually, extinguishers become obsolete—functional but unsupported.

OBSOLESCENCE INDICATORS:

Parts unavailable:

- Manufacturer no longer produces replacement valves, hoses, or components

- Compatible parts cannot be sourced from authorized suppliers

- Only generic or aftermarket parts available (often prohibited by NFPA)

- Service technicians decline to service due to parts unavailability

Outdated extinguishing agents:

- Halon extinguishers (production banned due to environmental concerns)

- Older clean agents replaced by more effective modern alternatives

- Dry chemical formulations superseded by improved versions

- Agent no longer manufactured or approved for recharge

Technology improvements:

- Modern extinguishers significantly more effective than older equivalents

- Newer units easier to use during emergencies

- Improved valve designs reducing maintenance needs

- Better pressure retention in current models

Regulatory changes:

- Equipment no longer meets current fire codes

- Mounting or placement standards changed

- Rating systems updated making old units non-compliant

- Specific types banned or restricted in certain applications

HALON EXTINGUISHERS—SPECIAL CASE

Halon production ceased in 1994 due to ozone depletion concerns. Existing halon extinguishers can still be serviced using recycled agent, but this raises questions about long-term viability.

HALON REPLACEMENT CONSIDERATIONS:

- Recycled halon supply continues shrinking

- Recharge costs increase as availability decreases

- Modern clean agents (FM-200, Novec 1230) perform equivalently

- Replacement eliminates future availability concerns

- Environmental responsibility supports transition

48Fire assists facilities with halon extinguisher replacement, identifying appropriate modern clean agent substitutes matching original application requirements.

UPGRADE OPPORTUNITIES

Replacing obsolete equipment provides opportunity to upgrade effectiveness.

MODERN IMPROVEMENTS:

- Higher agent discharge rates for faster fire suppression

- Improved nozzle designs for better coverage patterns

- Lighter-weight construction for easier handling

- Clearer operating instructions

- Better gauge visibility

- More durable mounting brackets

- Longer service intervals between maintenance

Facilities replacing 15-20 year old extinguishers with current models often see operational improvements justifying replacement beyond mere compliance necessity.

—

MAKING THE REPLACEMENT DECISION

EVALUATION FRAMEWORK

Systematic assessment prevents premature replacement while avoiding over-extension of aging equipment.

DECISION MATRIX:

| Factor | Keep/Repair | Replace |

|---|---|---|

| Age | Under 10 years with good condition | Approaching/exceeding lifespan |

| Test Status | Passing hydrostatic testing | Failed testing |

| Physical Condition | Minor wear, no significant damage | Extensive corrosion or damage |

| Service History | Minimal repairs needed | Recurring issues |

| Parts Availability | All components readily available | Obsolete/discontinued |

| Repair Cost | Under 40% of replacement | Exceeds 50% of replacement |

| Technology | Meets current needs | Better alternatives available |

GENERAL GUIDELINE:

Two or more “Replace” factors strongly indicate replacement makes better sense than continued service.

FINANCIAL PLANNING

Strategic replacement planning prevents budget surprises.

REPLACEMENT BUDGETING APPROACH:

Year 1-3: Most equipment serviceable, minimal replacements

- Budget 5-10% of equipment population for replacement

- Focus on obvious damage or failed testing

Year 4-7: Mid-life period, increasing replacements

- Budget 10-15% of population for replacement

- Target aging units approaching lifespan limits

- Proactive replacement of problem equipment

Year 8-10: Major replacement cycle

- Budget 20-30% of population for replacement

- Systematic replacement of equipment reaching end-of-life

- Consider complete refresh for consistency

Year 11+: Ongoing replacement of newer equipment reaching end-of-life

- Return to 10-15% annual budget

- Continuous rolling replacement maintains population health

This approach spreads costs over time rather than facing massive one-time replacement expenses when large equipment populations age simultaneously.

48Fire provides multi-year replacement planning and budgeting support helping facilities forecast equipment needs and costs.

—

REPLACEMENT PROCESS

ASSESSMENT AND PLANNING

Professional fire extinguisher replacement begins with comprehensive evaluation.

FACILITY ASSESSMENT:

1. Complete inventory of all fire extinguisher equipment

2. Age determination for entire population

3. Condition assessment identifying obvious replacement candidates

4. Service history review revealing problem equipment

5. Location analysis ensuring proper types and ratings for hazards

REPLACEMENT PRIORITIZATION:

- Immediate: Failed testing, extensive damage, safety hazards

- Short-term (3-6 months): Obsolete equipment, high service costs

- Medium-term (6-12 months): Approaching age limits, environmental exposure concerns

- Long-term (1-3 years): Good condition but aging, technology upgrade opportunities

SELECTION CRITERIA

Replacement extinguishers must match application requirements.

SPECIFICATION MATCHING:

- Fire class rating appropriate for protected hazards

- Size and capacity adequate for area protected

- Type of agent suitable for specific fire risks

- Mounting requirements compatible with location

- Environmental ratings matching exposure conditions

IMPROVEMENT OPPORTUNITIES:

- Upgrade to higher ratings where justified

- Switch to more effective agent types

- Improve accessibility with better placement

- Standardize on fewer models for simplified maintenance

- Add specialized units for specific hazard areas

48Fire provides expert guidance on fire extinguisher selection ensuring replacements meet both code requirements and operational needs.

INSTALLATION AND DOCUMENTATION

Professional replacement includes proper installation and compliance documentation.

INSTALLATION PROTOCOL:

1. Remove old equipment from service

2. Properly dispose of condemned units (destroyed to prevent reuse)

3. Verify mounting locations meet current code requirements

4. Install new extinguishers at proper heights

5. Attach clear signage above or near units

6. Update facility fire safety plans and diagrams

7. Train staff on new equipment locations and operation

DOCUMENTATION REQUIREMENTS:

- Updated equipment inventory with new serial numbers

- Manufacturing dates establishing service life baselines

- Initial inspection records

- Installation photographs

- Updated compliance files

- Staff training records

Complete documentation ensures replacement units start service with full compliance and proper tracking from day one.

—

DISPOSAL CONSIDERATIONS

PROPER EXTINGUISHER DISPOSAL

Condemned fire extinguishers require proper disposal, not simple trash disposal.

ENVIRONMENTAL CONCERNS:

- Extinguishing agents may require special handling

- Pressurized units present hazards if not properly depressurized

- Metal shells are recyclable but require preparation

- Some agents (halon, certain dry chemicals) have disposal restrictions

DISPOSAL PROCESS:

1. Complete depressurization by qualified technician

2. Valve removal and agent recovery (if agent is reusable/recyclable)

3. Shell puncturing or destruction preventing reuse

4. Separation of metals and components for recycling

5. Proper agent disposal per environmental regulations

48Fire handles all disposal requirements when replacing fire extinguisher equipment, ensuring environmentally responsible and regulation-compliant disposal.

AGENT RECOVERY AND RECYCLING

Some extinguishing agents can be recovered and reused.

RECOVERABLE AGENTS:

- Halon: Valuable due to limited supply, always recovered and recycled

- Clean agents: Often recoverable for reuse in other equipment

- CO2: Recyclable through proper recovery systems

NON-RECOVERABLE AGENTS:

- Dry chemical: Typically disposed as solid waste after moisture contamination check

- Wet chemical: Requires disposal as chemical waste

- Foam: Time-sensitive degradation usually prevents recovery

Professional service providers have systems for agent recovery maximizing recycling and minimizing environmental impact.

—

COST-BENEFIT ANALYSIS

REPLACEMENT INVESTMENT

Understanding fire extinguisher replacement costs helps facilities budget appropriately.

TYPICAL REPLACEMENT COSTS:

| Extinguisher Type | Size | Typical Cost Range |

|---|---|---|

| ABC Dry Chemical | 5 lb | $50-100 |

| ABC Dry Chemical | 10 lb | $75-150 |

| ABC Dry Chemical | 20 lb | $125-250 |

| CO2 | 10 lb | $150-300 |

| Water/Foam | 2.5 gal | $100-200 |

| Class K Wet Chemical | 6 liter | $200-400 |

| Clean Agent | Various | $400-800+ |

Prices include equipment only. Installation, disposal, documentation, and training typically add $50-150 per unit depending on facility requirements.

AVOIDING REPLACEMENT COSTS

While replacement becomes necessary eventually, proper maintenance extends equipment life and delays replacement needs.

LIFE EXTENSION STRATEGIES:

- Systematic monthly inspections catching problems early

- Prompt recharging after any use

- Environmental protection (avoid exposure to corrosive atmospheres)

- Proper mounting preventing physical damage

- Timely professional maintenance

- Quality recharge using approved agents

48Fire maintenance programs maximize fire extinguisher service life while ensuring equipment remains reliable, delaying replacement costs through proper care.

WHEN EARLY REPLACEMENT MAKES SENSE

Sometimes replacing serviceable equipment before absolute necessity provides benefits.

PROACTIVE REPLACEMENT SCENARIOS:

Fleet standardization:

- Replace mixed equipment types with standardized models

- Simplifies training, maintenance, and parts inventory

- May justify replacing functional but non-standard units

Technology upgrades:

- New extinguisher types significantly more effective

- Operational improvements justify early replacement

- Example: Replacing older dry chemical with modern wet chemical in kitchens

Facility renovations:

- Building modifications change fire protection needs

- Easier to replace during renovation than retrofit later

- Opportunity to update to current codes proactively

Risk reduction:

- High-value assets or critical operations justify maximum reliability

- Replace aging equipment preemptively rather than risk failures

- Peace of mind from knowing all equipment is well within service life

Strategic early replacement occasionally makes better business sense than extracting maximum life from every unit.

—

FREQUENTLY ASKED QUESTIONS

How long do fire extinguishers last?

Service life varies by type and maintenance quality. Rechargeable dry chemical extinguishers typically last 12-15 years with proper maintenance. CO2 and clean agent units may last 15-20 years. Disposable extinguishers should be replaced per manufacturer expiration dates, typically 10-12 years. Harsh environments shorten these lifespans. Proper maintenance including timely recharging, regular inspections, and successful hydrostatic testing maximize equipment life.

Can fire extinguishers be repaired instead of replaced?

Many issues can be repaired: valve replacement, hose replacement, recharging, seal replacement. However, certain conditions require replacement: failed hydrostatic testing, severe corrosion, obsolete parts unavailable, extensive physical damage, or when repair costs approach replacement cost. 48Fire provides honest assessment of repair viability versus replacement necessity.

What happens to old fire extinguishers when replaced?

Condemned extinguishers must be properly disposed. Professional services completely depressurize units, recover reusable agents (especially halon), destroy shells to prevent reuse, and recycle metal components. Some agents require special disposal per environmental regulations. 48Fire handles all disposal requirements ensuring environmentally responsible and compliant disposal when replacing equipment.

How much does fire extinguisher replacement cost?

Costs vary by type and size. Small ABC dry chemical units cost $50-150. Larger units, specialized types (Class K, clean agent), or wheeled units cost $200-800+. Installation, disposal, and documentation typically add $50-150 per unit. 48Fire provides transparent pricing and can often offer volume discounts for facilities replacing multiple units.

Should all fire extinguishers be replaced at the same time?

Not necessarily. Strategic replacement based on age, condition, and service history makes better financial sense than wholesale replacement. Facilities typically replace 10-30% of equipment population annually over multi-year cycles. This spreads costs and avoids massive one-time expenses. However, standardization benefits sometimes justify replacing functional units during planned upgrade projects.

Can fire extinguishers pass inspection but still need replacement?

Yes. Monthly visual inspections and even annual maintenance may not detect internal corrosion, pressure vessel fatigue, or agent degradation visible only during hydrostatic testing or internal examination. Equipment can appear serviceable externally while internal conditions warrant replacement. Systematic testing programs identify these hidden issues.

What should facilities do with fire extinguishers after fires?

Any extinguisher used during fires requires immediate professional service. Even partial discharge requires complete recharge. Units should be removed from service immediately, tagged as “used,” and sent for professional inspection and recharge or replacement. 48Fire provides emergency response for post-fire extinguisher service ensuring equipment returns to service properly or gets replaced if damage occurred.

Are newer fire extinguishers more effective than older models?

Generally yes. Manufacturing improvements over past 15-20 years include better valve designs, more efficient agent discharge, improved nozzles, clearer operating instructions, and better pressure retention. Modern Class K extinguishers significantly outperform older designs. Clean agents have improved substantially. Facilities replacing 15+ year old equipment typically see performance improvements with current models.

—

TAKE ACTION NOW

Fire extinguisher replacement decisions shouldn’t wait for equipment failures or compliance violations.

48Fire provides comprehensive fire extinguisher assessment services including:

✓ Complete equipment age and condition evaluation

✓ Replacement recommendations based on objective criteria

✓ Multi-year replacement planning and budgeting

✓ Professional installation of new equipment

✓ Proper disposal of condemned units

✓ Complete documentation for compliance verification

Schedule Your Assessment: Contact 48Fire at [/contact-us](/contact-us) for professional fire extinguisher evaluation. Our certified technicians will assess your current equipment, identify units requiring replacement, and develop cost-effective replacement strategies maintaining full fire protection and compliance.

Don’t wait for hydrostatic testing failures, fire marshal violations, or—worst case—equipment failures during actual fires. Proactive assessment and strategic replacement keep facilities protected with reliable equipment.