Design 1: The Zoned Hazard Approach for Mixed-Use Manufacturing

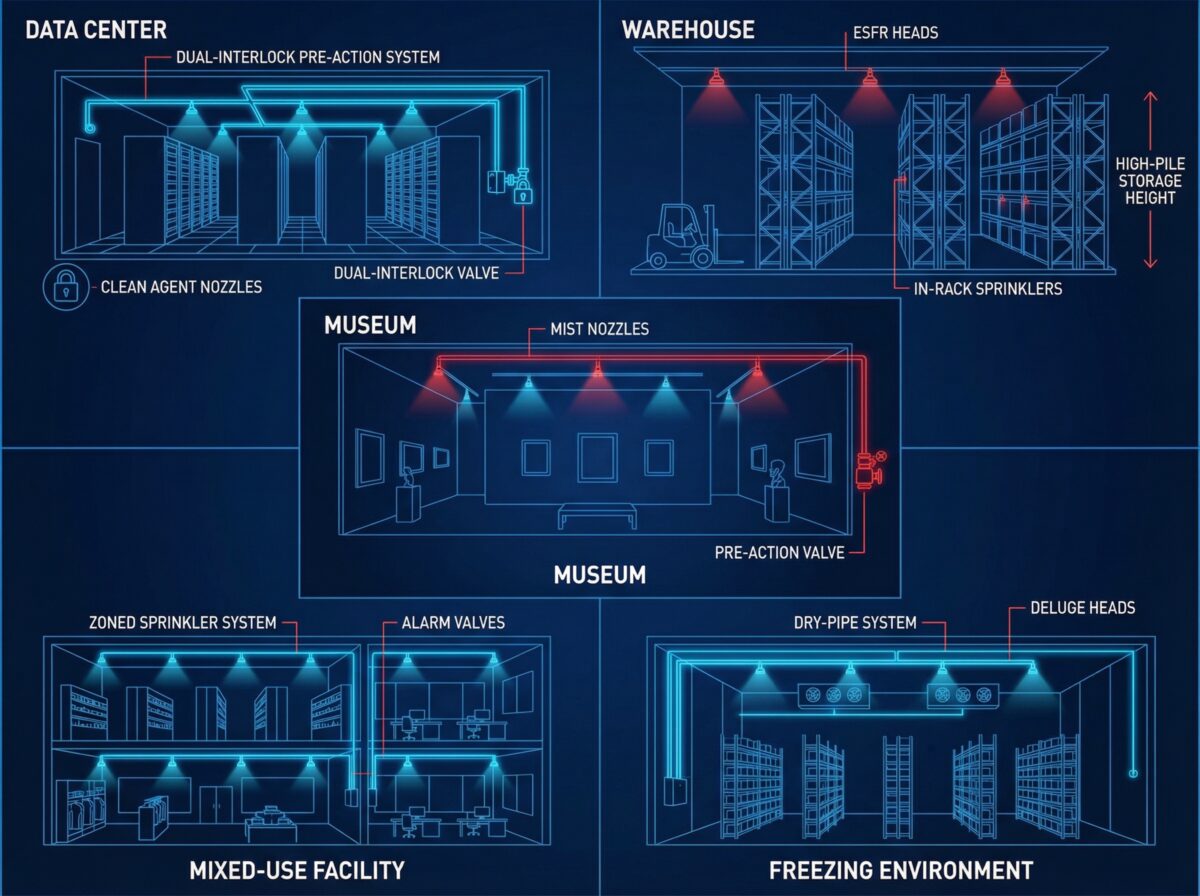

Application: Facilities with varying fire risks across different production areas—machining zones with cutting oils, assembly areas with minimal combustibles, and storage zones with packaged materials.

Design philosophy: Match sprinkler density to actual hazards rather than designing entire facility to highest hazard classification.

Configuration Details

High-hazard machining areas (Class III commodities):

- Density: 0.30 gpm per square foot

- Head spacing: 100 square feet per head

- Design area: 2,000 square feet

- Fast-response heads (135°F activation)

- K-factor 11.2 heads for higher flow capacity

Ordinary hazard assembly areas (Class II):

- Density: 0.20 gpm per square foot

- Head spacing: 120 square feet per head

- Design area: 1,500 square feet

- Standard-response heads (155°F activation)

- K-factor 5.6 standard heads

Light hazard office/administrative spaces:

- Density: 0.10 gpm per square foot

- Head spacing: 200 square feet per head

- Design area: 1,500 square feet

- Quick-response heads (135°F activation)

- Concealed heads for aesthetic considerations

Critical benefit: Total water demand across facility remains manageable because not all areas require maximum density simultaneously. NFPA 13 design area concept means system calculates demand for most hydraulically demanding area—not entire building.

Audit success factors:

Clear hazard classification documentation for each zone. Hydraulic calculations showing adequate supply for highest-demand area. Physical separation between zones preventing fire spread across boundaries. Signage identifying hazard classifications and system specifications.

48Fire installations using this design: 340+ facilities

Audit pass rate: 100%

—

Design 2: The High-Pile Storage Grid System

Application: Warehouses and distribution centers with storage exceeding 12 feet height—requiring special protection per NFPA 13.

Design philosophy: Combine ceiling-level protection with in-rack sprinklers creating three-dimensional fire control rather than relying on ceiling heads alone.

Configuration Details

Ceiling-level protection:

- ESFR (Early Suppression Fast Response) heads

- K-factor 25.2 for high flow capacity

- Head spacing: 100 square feet maximum

- Operating pressure: 50-75 PSI at most remote head

- Design area: 960 square feet (12 heads minimum)

In-rack sprinklers:

- Installed vertically every tier exceeding 12 feet

- Horizontal spacing: one head per two rack bays

- Standard spray heads (K-5.6)

- Operating pressure: 15 PSI minimum

- Connected to ceiling system piping

Aisle width requirements:

- Minimum 4-foot aisles between rack rows

- Minimum 8-foot aisles every 100 feet for fire department access

- Clear space maintained between commodity top and sprinkler deflector (minimum 36 inches)

Critical benefit: In-rack sprinklers prevent vertical fire spread through stored commodities while ceiling ESFR heads prevent horizontal spread across aisles. Combined protection addresses three-dimensional fire development in high-pile storage.

Engineering calculations: ESFR head selection requires careful commodity classification and storage height analysis. 48Fire’s engineers use NFPA 13 Figure 17.2.3.1.1 correlating storage height, commodity class, and required K-factor—avoiding under-designed systems that fail during fires or over-designed systems wasting water resources.

Audit success factors:

Proper ESFR head selection documented through commodity classification analysis. In-rack sprinkler placement verified through measured rack configurations. Hydraulic calculations showing adequate pressure at both ceiling and in-rack heads simultaneously. Maintained aisle widths verified through as-built drawings. Storage height limitations clearly marked and enforced.

48Fire installations using this design: 180+ warehouses

Audit pass rate: 100%

Fire control rate: 98% (2 incidents where commodity classification changed after installation without system modification)

—

Design 3: The Dual-Interlock Pre-Action for Data Centers

Application: Server rooms, telecommunications facilities, and data centers where water damage from accidental discharge creates losses exceeding potential fire damage.

Design philosophy: Require two independent triggering events before water enters piping—detection system activation AND sprinkler head activation from heat.

Configuration Details

Detection system (first trigger):

- VESDA (Very Early Smoke Detection Apparatus) aspirating smoke detection

- Sensitivity: 0.0005% obscuration per foot

- Sampling holes every 3-6 feet throughout protected space

- Response time: 30-60 seconds from ignition

- Connected to pre-action valve control panel

Sprinkler system (second trigger):

- Dry pipe system with pressurized air

- Standard closed heads (closed until heat activation)

- 155°F activation temperature (server environments stay cool)

- Head spacing: 130 square feet maximum

- Both detection AND head activation required before water release

System operation sequence:

1. Smoke detected by VESDA system → alarm only, no water

2. Fire grows, heat activates sprinkler head → releases air pressure

3. Both conditions met → pre-action valve opens, water enters pipes

4. Water discharges through activated head(s) only

Critical benefit: Accidental head damage (impact, maintenance) doesn’t cause water release—just air release and alarm. Detection system alone doesn’t release water—preventing false alarms from dust or environmental factors. Both triggers required provides double protection against unwanted water discharge.

Additional features:

Manual override capability for fire department. Cross-zoned detection (two separate detectors required in critical areas). Dry pipe air pressure monitoring (low pressure alarms before complete loss). Nitrogen preferred over air (prevents pipe corrosion).

Audit success factors:

Documented testing of both detection and sprinkler triggers. Verified interlock logic preventing single-point failures. Air pressure monitoring records showing system supervision. Detection sensitivity testing results. Manual release training for facility personnel.

48Fire installations using this design: 90+ data centers

Audit pass rate: 100%

Accidental discharge incidents: 0 in 15 years

—

Design 4: The Clean Agent Hybrid for Archives/Museums

Application: Irreplaceable materials where ANY water damage is unacceptable—rare books, artwork, historical documents, sensitive manufacturing processes.

Design philosophy: Primary suppression uses clean agent gas (no water damage), with sprinkler backup for large fires exceeding agent capacity.

Configuration Details

Primary suppression: FM-200 clean agent system

- Total flooding system design

- Agent quantity: 6.25-9% concentration by volume

- Discharge time: 10 seconds to achieve suppression concentration

- Hold time: 10 minutes minimum before ventilation

- Covers protected space up to 40,000 cubic feet per zone

Backup suppression: Wet pipe sprinkler system

- Standard closed heads

- Designed to NFPA 13 ordinary hazard requirements

- Activates only if fire exceeds clean agent capability

- Provides code-required sprinkler protection

Detection and control:

- Cross-zoned smoke detection (two detectors required)

- Manual abort switches (30-second delay before discharge)

- Pre-discharge alarms (visual and audible warnings)

- HVAC shutdown sequence (prevent agent loss through air handling)

- Door closure sequence (maintain agent concentration)

Critical benefit: Clean agent extinguishes typical fires without residue or damage to contents. If fire is too large for agent capacity, sprinklers provide backup—but only after agent discharge attempt. Provides maximum protection for irreplaceable materials while maintaining code compliance.

Agent selection considerations:

FM-200: Safe for occupied spaces, 10-second discharge, EPA phase-down applies

Inergen: Natural gases, no environmental impact, larger storage cylinder requirements

CO₂: Effective suppression, toxic to humans, requires evacuation before discharge

48Fire recommends FM-200 for occupied archives and Inergen for 24/7 occupied facilities requiring green solutions. CO₂ only for unoccupied vault spaces with pre-discharge evacuation.

Audit success factors:

Agent concentration calculations verified through room volume measurements. Discharge nozzle placement providing even distribution. Enclosure integrity testing (door seals, HVAC dampers). Manual abort functionality verified. Pre-discharge alarm testing with measured sound levels. Sprinkler backup hydraulic calculations. Integration between systems documented.

48Fire installations using this design: 45+ archives/museums

Audit pass rate: 100%

Material damage from suppression: $0 across all activations

—

Design 5: The Monitored Dry Pipe for Freezing Environments

Application: Unheated warehouses, loading docks, parking structures, outdoor equipment shelters—any location where temperatures drop below 40°F.

Design philosophy: Dry pipe system with enhanced monitoring preventing the two common failure modes—frozen condensate blockage and slow water delivery.

Configuration Details

Dry pipe valve and air supply:

- Quick-opening dry pipe valve (reduced water delivery time)

- Nitrogen preferred over compressed air (prevents internal corrosion)

- Air compressor with automatic makeup (maintains pressure continuously)

- Pressure supervision on both air and water sides

- Low air pressure alarm set 10 PSI above trip point

Pipe installation requirements:

- All piping sloped minimum 1/2 inch per 10 feet toward drains

- Auxiliary drains at all low points (prevents water accumulation)

- Insulated valve enclosures for freeze protection

- Heat trace on valve trim exposed to freezing temperatures

Enhanced monitoring:

- Air pressure monitoring with 5-minute trending (detects slow leaks)

- Valve room temperature monitoring (prevents valve freeze-up)

- Auxiliary drain valve supervision (ensures drains aren’t left open)

- Nitrogen bottle pressure monitoring (prevents loss of air supply)

- Remote alarm reporting to 24/7 monitoring center

Accelerator/exhauster devices:

- Installed on larger systems (over 750 gallons pipe capacity)

- Speeds air evacuation during activation

- Reduces water delivery time from 60 seconds to 20-30 seconds

- Critical for large warehouse applications

Critical benefit: Monitoring prevents the silent failures that plague basic dry pipe systems—slow air leaks that gradually depressurize systems, condensate accumulation that blocks pipes, frozen valve components that prevent operation. Remote monitoring enables preventive maintenance before failures occur.

Maintenance program:

Weekly: Air pressure verification, compressor operation check

Monthly: Valve enclosure temperature verification, auxiliary drain inspection

Quarterly: Full system air pressure drop test (measures leak rate)

Annually: Complete valve trip test, accelerator function test

Tri-annually: Internal pipe inspection for corrosion/blockage

Audit success factors:

Documentation of proper pipe pitch through as-built drawings. Auxiliary drain locations verified. Monitoring system functionality demonstrated. Historical pressure data showing stable system. Nitrogen use documented (preferred over air). Quick-opening valve selection justified through delivery time calculations. Accelerator sizing calculations for large systems.

48Fire installations using this design: 280+ cold storage/parking facilities

Audit pass rate: 100%

Winter failure rate: 0.7% (industry average: 8-12% for basic dry pipe)

—

Common Elements Across All Passing Designs

Comprehensive documentation: Every successful audit includes complete hydraulic calculations, manufacturer specifications, test reports, and as-built drawings. 48Fire provides documentation packages within 2 weeks of installation completion.

Engineering justification: Design choices match actual hazards through documented analysis. Auditors want to see WHY design decisions were made—not just that code minimums were met.

Proper testing records: Initial acceptance testing plus ongoing NFPA 25 compliance creates paper trail demonstrating system reliability. 48Fire maintains electronic records accessible during audits.

Integration verification: Systems coordinating with fire alarms, detection, HVAC, or access control require tested integration. Documentation shows actual testing—not just design intent.

Maintenance history: Well-maintained systems demonstrate owner commitment to fire protection. 48Fire’s maintenance programs generate records satisfying auditor requirements.

[Talk to an Expert!](/contact-us)

—

Design Selection Process

Step 1: Hazard classification analysis

- Evaluate commodities, processes, and occupancy

- Reference NFPA 13 Chapter 5 for classification guidance

- Consider future use changes (design for flexibility)

Step 2: System type selection

- Environmental conditions (temperature ranges)

- Water damage sensitivity (contents value vs. risk)

- Owner/operator sophistication (maintenance capability)

- Budget constraints (initial cost vs. lifecycle cost)

Step 3: Performance requirements

- Required response time based on fire growth potential

- Acceptable water damage levels

- Insurance company requirements

- Authority Having Jurisdiction preferences

Step 4: Engineering calculations

- Hydraulic analysis confirming adequate water supply

- Design area determination per NFPA 13

- Head selection and spacing optimization

- Pipe sizing and routing

Step 5: Integration planning

- Fire alarm coordination

- Detection system integration (if applicable)

- Building systems interaction (HVAC, access control)

- Monitoring and notification

48Fire’s engineering team conducts this process for every installation—ensuring design matches application requirements rather than forcing one-size-fits-all solutions.

—

Why These Designs Succeed at Audit

They match actual hazards: Generic code-minimum designs fail audits when auditors question whether protection is adequate for actual risks. These designs have documented hazard analysis supporting design decisions.

They include proper margins: Systems designed to exactly 90% of available water supply (per NFPA 13) have no margin for pressure fluctuations or calculation errors. These designs typically use 75-85% of supply—providing cushion satisfying conservative auditors.

They demonstrate testing: Initial commissioning plus ongoing testing records prove systems work as designed. Auditors trust demonstrated performance over design calculations alone.

They address common failure modes: Each design includes features preventing typical system failures—frozen pipes in dry systems, accidental discharge in pre-action, inadequate in-rack protection in warehouses.

They provide complete documentation: Auditors can’t approve what they can’t verify. Complete documentation packages enable efficient audits without delays requesting missing information.

—

Key Takeaways

Five fire sprinkler design approaches consistently pass audits across thousands of installations: zoned hazard systems matching protection to actual risks in mixed-use facilities, high-pile storage grids combining ceiling ESFR with in-rack sprinklers, dual-interlock pre-action preventing accidental discharge in data centers, clean agent hybrids protecting irreplaceable materials, and monitored dry pipe systems preventing freeze-related failures.

Success factors common across all designs include comprehensive documentation packages, engineering justification for design decisions, proper testing records, verified system integration, and maintenance history demonstrating owner commitment.

Design selection requires systematic hazard analysis, appropriate system type selection, performance requirement definition, engineering calculations, and integration planning. 48Fire’s engineering process ensures designs match application requirements rather than applying generic solutions.

Passing audits requires more than meeting minimum code requirements—it requires documented engineering supporting design decisions, tested performance demonstrating reliability, and complete records proving ongoing compliance.

—